The cycle tune-up must be performed at initial installation of the indoor cycle for optimal performance and

longevity. Please read and follow all instructions below. If the indoor cycle is not installed and tuned as

described, components may wear excessively and the indoor cycle may become damaged. If you have

questions about the installation, please contact service@indoorcycling.com.

Note: Some maintenance procedures require acid-, silicone- and solvent free spray lubricant

(for

example BRUNOX),

and White Lithium grease

.

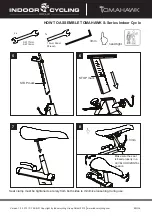

1.

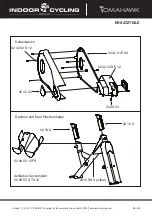

Make sure that the indoor cycle is level. If the indoor cycle rocks on the floor, turn the

leveling feet underneath the front and/or rear stabilizer until the rocking motion is eliminated.

2.

Verify Emergency brake function to assure that emergency brake functions correctly.

3.

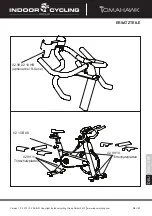

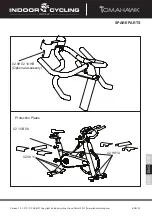

Brake pad calibration: Turn resistance knob counterclockwise as far as possible (minimum bra-

king effect), verify that there is a slight separation of the brake pad from flywheel. Brake pad

should barely touch the flywheel when resistance knob is turned counter-clockwise as far as it

can go.

4.

Apply spray lubricant to the brake pad using the lubrication holes on the plastic part or the brake

pad and externally on the felt pad. Make sure brake pad is thoroughly soaked from end to end

with lubricant spray. Then, wipe the excess off from the flywheel.

* Best Practice: Use a refillable spray bottle filled with non-aerosol

acid-, silicone- and solvent

free

spray lubricant purchased by the gallon (3.7 L) at the local hardware store.

5.

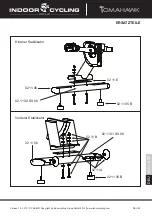

Apply Lithium grease to the threads on the lower end of the brake rod. First, turn the Resistance

knob clockwise until it stops. Apply a small amount of white lithium grease to the threads on the

brake rod above the two lock nuts. Then, turn the resistance knob counter-clockwise until it stops.

6.

Apply Lithium grease on the metal threads of all the adjustment knobs.

7.

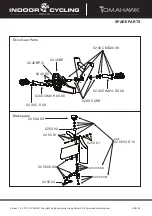

Verify four (4) Allen nuts on RS pulley for tightness. If loose, apply LocTite Threadlocker Blue-242

and retighten.

8.

Verify R and L crank arm Allen bolts for tightness. If loose, apply LocTite Threadlocker Blue-242

and retighten.

9.

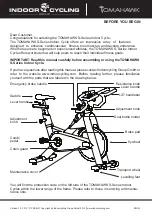

Verify belt tension. Check if belt drive is firmly tightened and does not slip while riding under resis-

tance load. In case that the belt slips, proceed using the adjustment technique as described on

page (17). Please note that a belt drive gear never shows slack. In case of adjustment do

not apply too much tension.

10.

Wipe down bike frame with rag moistened with solvent free spray lubricant

11.

Some parts of the indoor cycle may become loose during shipment. Check crank arms, check all

exposed screws, bolts, and nuts, and make sure that they are properly tightened.

Customer Service

1.

Provide basic maintenance instructions to client and direct them to detailed maintenance instruc-

tions (page 13-19).

2.

Sign-off sheet provided to client to confirm explanation of maintenance procedures/manual and

verification of condition of bikes

Version 1.0 2013 IC-TKSB-01 Copyright by Indoorcycling Group GmbH 2013

|

www.indoorcycling.com

ENG 8

INITIAL INSTALL CHECKS