15

industrialaircontractor.com

Please contact 1-888-895-4549 for further assistance.

4

Running the air compressor

WARNING:

Always ensure the switch is in the OFF

position and regulator pressure gauge reads zero before

changing air tools or disconnecting the hose from the air

outlet. Failure to do so could result in possible serious

personal injury.

WARNING:

Your tool may require more air consumption

than this air compressor is capable of providing. Check the

tool manual to avoid damage to the tool or risk personal

injury.

NOTE:

Always use the minimum amount of air flow with

the pressure regulator knob. Using a higher pressure than

needed will drain air from the tank more rapidly and cause

the unit to cycle on more frequently.

□

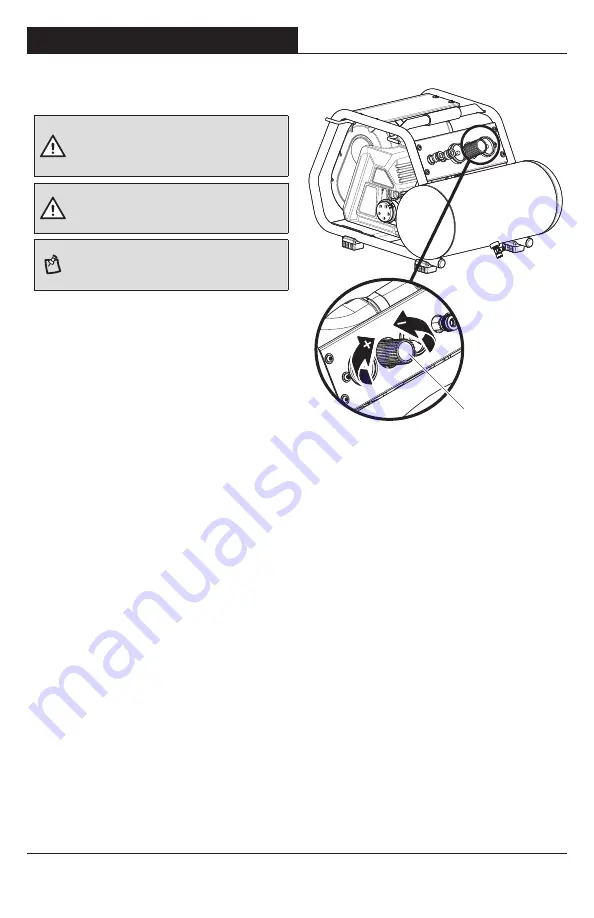

Rotate the pressure regulator knob (1) to

the desired line pressure. Turning the knob

clockwise (+) increases air pressure at the

outlet; turning counterclockwise (-) reduces air

pressure at the outlet.

□

If using an inflation accessory, control the

amount of air flow with the pressure regulator

knob (1). Turning the knob fully counterclockwise

will completely stop the flow of air.

□

When finished, always drain the tank and unplug

the unit. Never leave the unit plugged in and/or

running unattended.

1

Operation (continued)