19

industrialaircontractor.com

Please contact 1-888-895-4549 for further assistance.

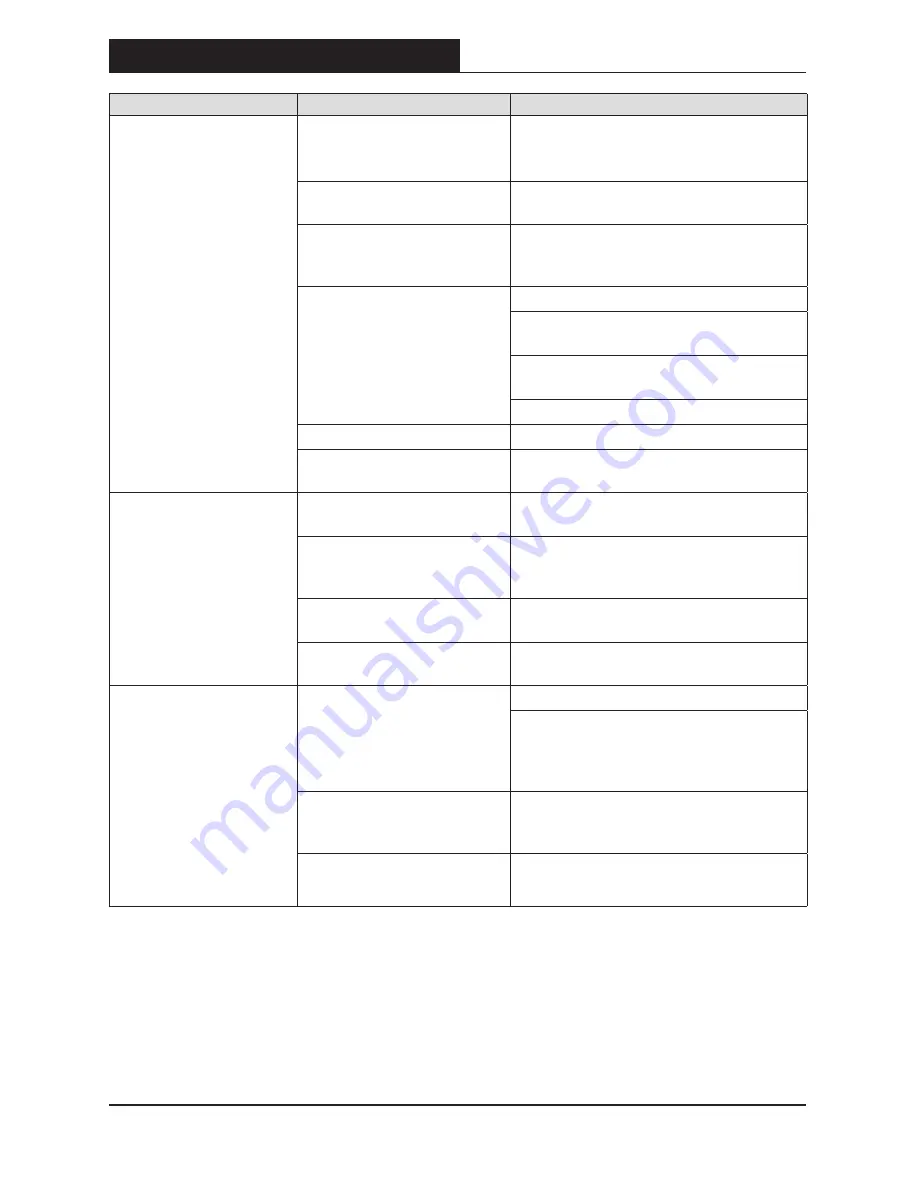

Problem

Possible Cause

Solution

The compressor does not

run.

□

There is a loss of power or

the motor is overheated.

□

Check for proper use of extension cord.

□

There is no power to the

unit.

□

Check to be sure the unit is plugged in.

□

The circuit breaker has

tripped or a fuse has blown

at the main power source.

□

Check the fuse/breaker.

□

The thermal overload

protector is actuated.

□

Turn the air compressor OFF ( O ).

□

Unplug the air compressor and wait until

the compressor cools down.

□

Plug the air compressor into an approved

outlet.

□

Turn the air compressor AUTO ( I ).

□

The pressure switch is bad.

□

Bring the compressor to a service center.

□

The compressor has reached

automatic shutoff pressure.

□

Release the air from the tank until the

compressor restarts automatically.

The motor hums while

running slowly, or it does not

run at all.

□

There is low voltage from

the power source.

□

Call an electrician.

□

The wrong gauge wire or

length of extension cord is

being used.

□

Check for proper gauge wire and cord

length.

□

There is a shorted or open

motor wiring.

□

Bring the compressor to a service center.

□

There is a defective check

valve or unloader.

□

Bring the compressor to a service center.

The fuses blow or circuit

breaker trips repeatedly.

□

The incorrect fuse type is

being used.

□

Check for the proper fuse.

□

Use a time-delay fuse. Disconnect other

electrical appliances from the circuit

or operate the compressor on its own

branch circuit.

□

The wrong gauge wire or

length of extension cord

is used.

□

Check for the proper gauge wire and

cord length.

□

There is a defective check

valve or unloader.

□

Bring the compressor to a service center.

Troubleshooting