7 - ENG

200-2824

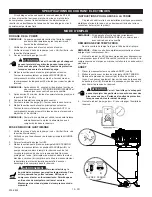

Main Power Disconnect

Install a main power disconnect switch in the power line to

the compressor, near the compressor’s location. It is operated

manually, but when it is in the ON position, the compressor

will start up or shut down automatically based on air demand.

ALWAYS operate this switch to OFF when the compressor is not

being used.

Pressure switch

(see

A

)

This switch turns on the compressor. It is operated manually,

but when in the ON position, it allows the compressor to start up

or shut down automatically, without warning, upon air demand.

ALWAYS set this switch to OFF when the compressor is not

being used.

WARNING:

For your safety, tank pressure is preset

within the switch and must never be tampered with.

This switch must not be adjusted by the operator; doing so

will void the warranty. The pressure switch controls the level of

air pressure in the tank by automatically starting and stopping the

motor, as required to maintain the factory preset pressure level.

The pressure switch also automatically bleeds pressure from

the pump head when the pump stops. This feature eliminates

back pressure in the pump, ensuring easier starting.

Tank Safety Valve

(see

B

)

Used to allow tank pressure to escape into the atmosphere.

If the pressure switch does not shut off the compressor at it’s “cut-

out” pressure setting, the safety valve will protect against high

pressure by releasing tank pressure at it’s factory set pressure

(slightly higher than the pressure switch “cut-out” setting). To

operate manually, pull the ring on the valve to relieve air pressure

in the tank.

Pressure Release Valve

(see

C

)

The pressure release valve (located on the bottom of the

pressure switch), is designed to release compressed air from the

compressor head and outlet tube when the compressor reaches

“cut-out” or is shut off. The pressure valve allows the motor to

restart freely. When the motor stops running, air will be heard

escaping from this valve for a few seconds. No air should be

heard leaking when the motor is running or after brief release

after reaching “cut-out” pressure.

Tank Pressure Gauge

(see

D

)

This gauge measures the pressure level of the air stored

in the tank. It is not adjustable by the operator, and does

not

indicate line pressure.

COMPRESSOR CONTROLS

ELECTRICAL POWER REQUIREMENTS

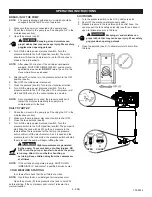

Fig. 3

A

B

D

(Measures pressure in

tank, not line pressure)

C

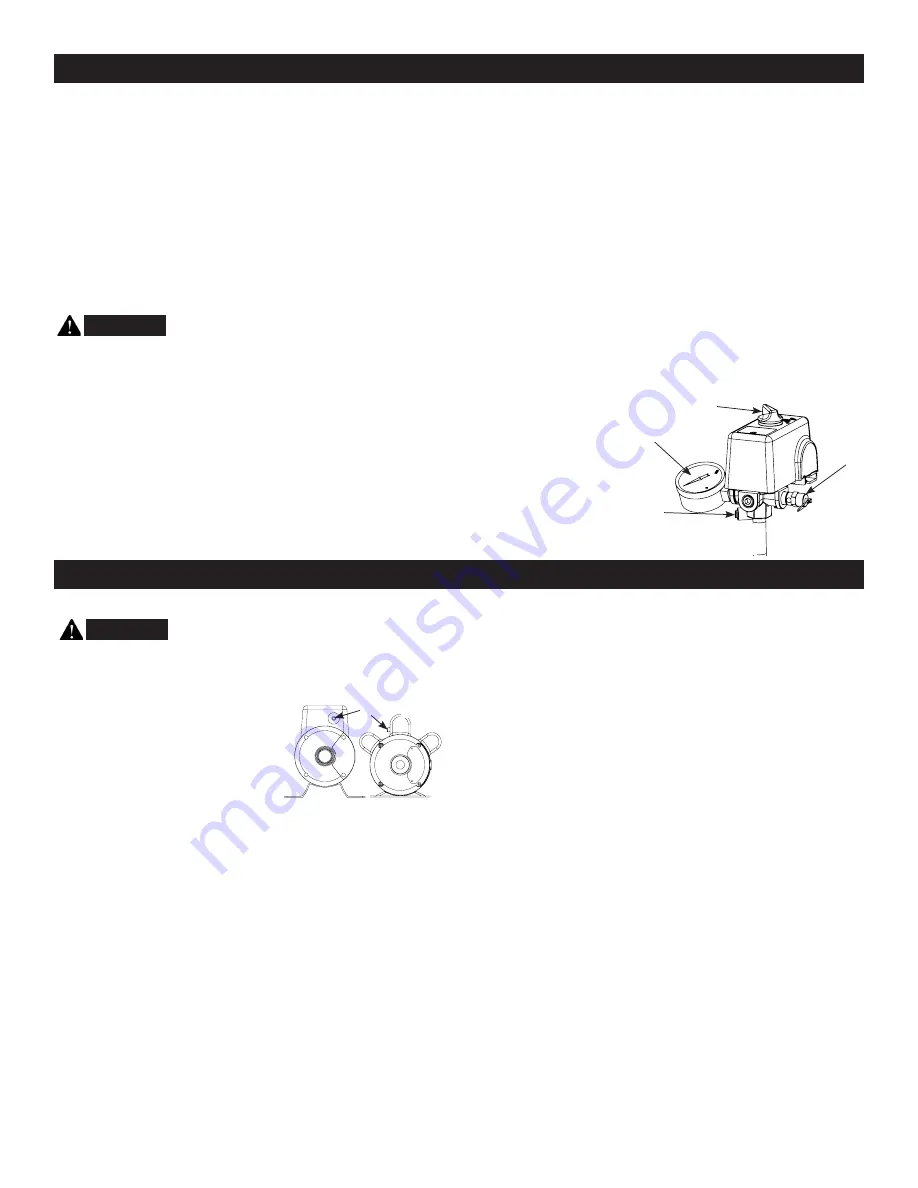

WARNING:

Ensure that all guards and shrouds are in

place before pressing the reset switch to restart the

motor.

TOPS senses both temperature and current, providing

more complete motor overload

protection than a magnetic starter,

which senses only current. If TOPS

senses an overload condition, it

will automatically shut down the

compressor. Allow 10-15 minutes

for the unit to cool down, than press

the reset button on the motor to restart the compressor.

If the motor shuts down because of overload, wait 10–15

minutes so the motor can cool down, then press (

NEVER force

)

the reset switch (see

E

) to restart the motor (see

Fig. 4

).

Refer to the air compressor’s serial label for the unit’s voltage

and amperage requirements. Ensure that all wiring is done by

a licensed electrician, in accordance with the National Electrical

Code. Use electrical conduit to protect the wiring.

For best performance and reliable starting, the air

compressor must be installed on a dedicated circuit, as

close as possible to the electrical power panel.

Provide

circuit breaker or fuse protection at your main power panel. Use

time delay fuses on the circuit, because the compressor will

momentarily draw several times its specified amperage when first

started.

Install a main power disconnect switch in the line from the

panel to the compressor. The main power disconnect switch

must be located near the compressor, for ease of use and safety.

When turned OFF, the main power disconnect switch shuts off all

power to the compressor. When it is turned ON, the compressor

will start and stop automatically, controlled by the pressure

switch.

Low voltage will cause difficult starting or an overload. Low

voltage can be caused by a low supply voltage from the local

power company, other equipment running on the same line, or

inadequate wiring. If any other electrical devices are drawing from

the compressor’s circuit, it may fail to start.

Low voltage to the compressor can be caused by a

supply wire of insufficient gauge for the distance between the

compressor and the power source. The longer the distance, the

larger the wire gauge (lower the number) must be, to overcome

the inherent voltage loss caused by the wire resistance. Refer to

the National Electrical Code to determine proper wire size for your

circuit.

If the wiring is not adequate, the input voltage will drop by 20

to 40 volts at startup. Low voltage or an overloaded circuit can

result in sluggish starting that causes the circuit breaker to trip,

especially in cold conditions.

This product must be connected to a grounded, metallic,

permanent wiring system, or an equipment - grounding terminal

or lead on the product.

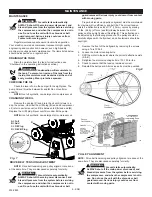

MOTOR RESET SWITCH

Fig. 4

E

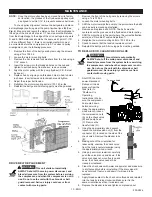

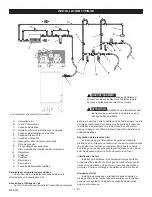

ELECTRICAL WIRING

MAIN POWER PANEL

MAIN POWER DISCONNECT SWITCH

LOW VOLTAGE PROBLEMS

GROUNDING INSTRUCTIONS

Summary of Contents for ILA5148080

Page 35: ...200 2824 35 200 2824 NOTES...