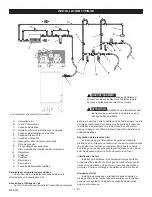

9 - ENG

200-2824

MAINTENANCE

This unit starts automatically.

ALWAYS shut off the main power disconnect, and

bleed all pressure from the system before servicing

the compressor, and when the compressor is not in

use. Do not use the unit with the shrouds or belt

guard removed. Serious injury could occur from

contact with moving parts.

Regular maintenance will ensure trouble–free operation.

Your electric powered air compressor represents high–quality

engineering and construction; however, even high–quality

machinery requires periodic maintenance. The items listed below

should be inspected on a regular basis

Drain the moisture from the tank (for instructions, see

“Shutdown” in the operating instructions section).

Condensation will accumulate in

the tank. To prevent corrosion of the tank from the

inside, this moisture must be drained at the end of

every workday. Wear protective eyewear.

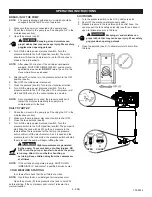

Check the level of oil in the pump with the sight glass. The

pump oil level must be between

A

and

B

. Do not overfill or

underfill.

NOTE:

Use full synthetic, non-detergent air compressor oil.

Remove the oil plug (

C

) and drain the oil until it slows to a

drip, then close. Unscrew the oil fill plug (

D

) and add compressor

oil (refer to parts manual) until it is between full (

A

) and add (

B

).

Replace the oil fill plug. Never overfill or under fill the pump.

NOTE:

Use full synthetic, non-detergent air compressor oil.

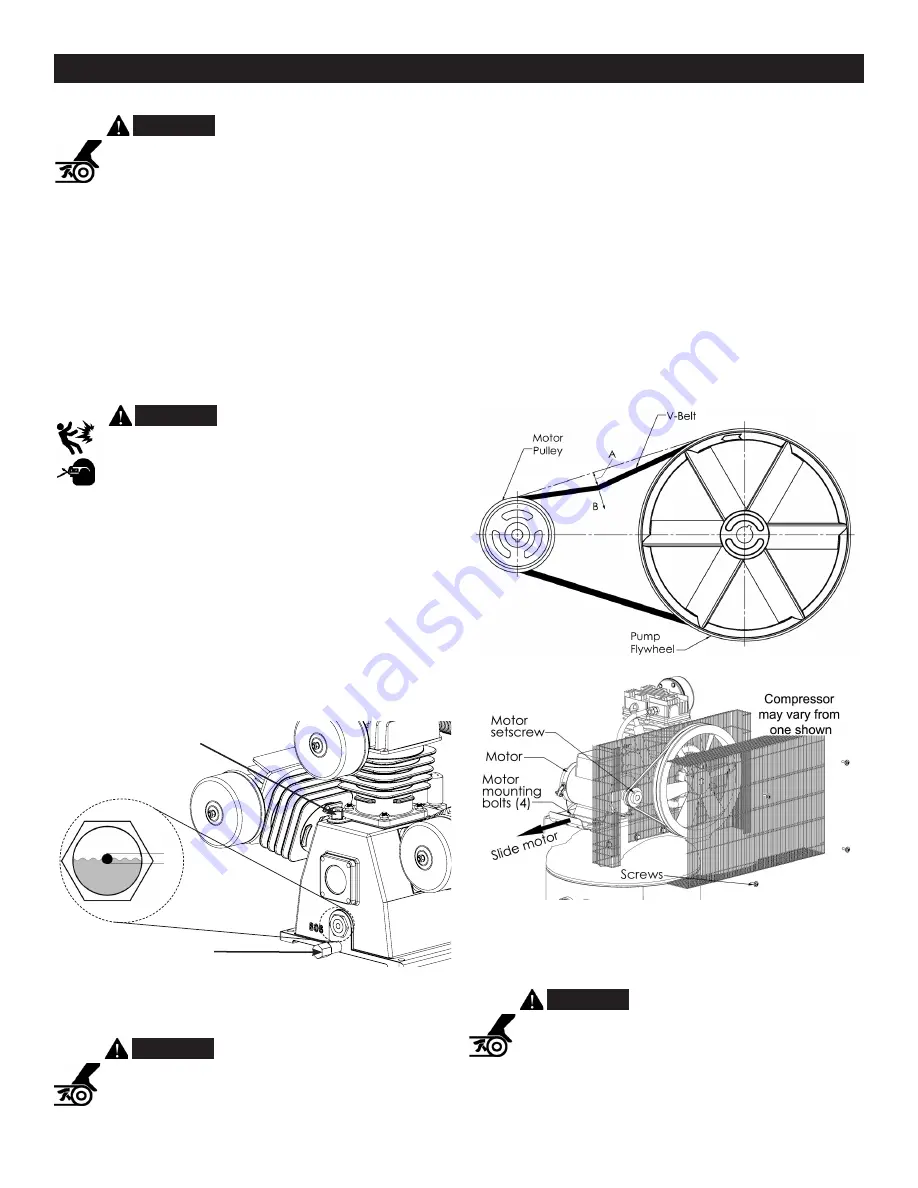

NOTE:

Drive belt tensioning and pulley alignment are done

at the same time. They are discussed separately for clarity.

This unit starts automatically.

ALWAYS shut off the main power disconnect, and

bleed all pressure from the system before servicing

the compressor, and when the compressor is not in

use. Do not use the unit with the shrouds or belt

guard removed. Serious injury could occur from contact

with moving parts.

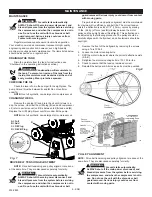

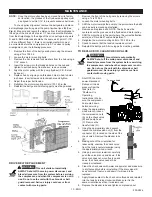

Proper belt tension and pulley alignment must be maintained

for maximum drive efficiency and belt life. The correct tension

exists if a deflection (see

A

) of 1/2” (13 mm) occurs by placing

10 lbs. (4.6 kg) of force (see

B

) midway between the motor

pulley and the pump flywheel (See

Fig. 8

). This deflection can

be adjusted by the following procedure. The pulley should be

carefully aligned with the flywheel, and all setscrews should be

kept tight.

1. Remove the front of the beltguard by removing the screws

using a Torx T25 bit.

2. Loosen the motor mounting bolts.

3. Shift the motor to the point where the correct deflection exists

(A & B).

4. Retighten the motor mounting bolts to 130-180 in.-lbs.

5. Check to ensure that the tension remained correct.

6. Reinstall the belt guard. All moving parts must be guarded.

NOTE:

Drive belt tensioning and pulley alignment are done at the

same time. They are discussed separately for clarity.

This unit starts automatically.

ALWAYS shut off the main power disconnect, and

bleed all pressure from the system before servicing

the compressor, and when the compressor is not in

use. Do not use the unit with the shrouds or belt

guard removed. Serious injury could occur from

contact with moving parts.

MAINTENANCE

DRAINING THE TANK

CHECKING THE OIL

CHANGING THE OIL

WARNING:

DRIVE BELT TENSION ADJUSTMENT

Fig. 8

WARNING:

PULLEY ALIGNMENT

WARNING:

WARNING:

A = Full

B = Add

C = Oil Plug

D = Oil Fill Plug

Fig. 7

D

C

B

A

Summary of Contents for ILA5148080

Page 35: ...200 2824 35 200 2824 NOTES...