11 - ENG

200-2927

MAINTENANCE

SERVICE INTERVAL

Perform the following maintenance at the intervals indicated below.

Daily

or after

each use

Monthly or

Every 50

Hours

1 Year or

200 Hours

After first 8 hours

and then every 500

operating hours

Inspect air filters (clean or replace as necessary)

•

Check pump oil level

•

Change pump oil

(Use full synthetic, non-detergent air compressor oil.)

•

Operate the tank safety valve

•

Check belt tension

•

Drain tank

•

Check and tighten all bolts

(do not over tighten)

•

10. Perform the “Break-in of the pump” procedure in the

Operating Instructions to make sure there are no leaks and

the check valve is working properly.

A dirty air filter

will reduce the

compressor’s

performance and life.

To avoid any internal

contamination of the

pump, the filters should

be cleaned frequently,

and replaced on a

regular basis. Felt filters

should be cleaned in

warm, soapy water,

rinsed, and allowed

to air dry before

reinstallation. Paper filters should be replaced when dirty. Do

not allow the filters to become filled with dirt or paint. If the filter

becomes filled with paint, it should be replaced. Direct exposure

to dirty conditions or painting areas will void your warranty.

Pull the tank safety valve daily to ensure that it is operating

properly and to clear the valve of any possible obstructions.

Check that all connections are tight. A small leak in any of

the hoses, transfer tubes, or pipe connections will substantially

reduce the performance of your air compressor. If you suspect

a leak, spray a small amount of soapy water around the area

of the suspected leak with a spray bottle. If bubbles appear,

repair or replace the faulty component. Do not over tighten any

connections.

Before storing the compressor for a prolonged period, use

an air blow gun to clean all dust and debris from the compressor.

Disconnect the power cord and coil it up. Pull the tank safety

valve to release all pressure from the tank. Drain all moisture from

the tank. Clean the filter elements and filter housings; replace

the elements if necessary. Drain the oil from the pump crankcase

and replace it with new oil. Cover the entire unit to protect it from

moisture and dust.

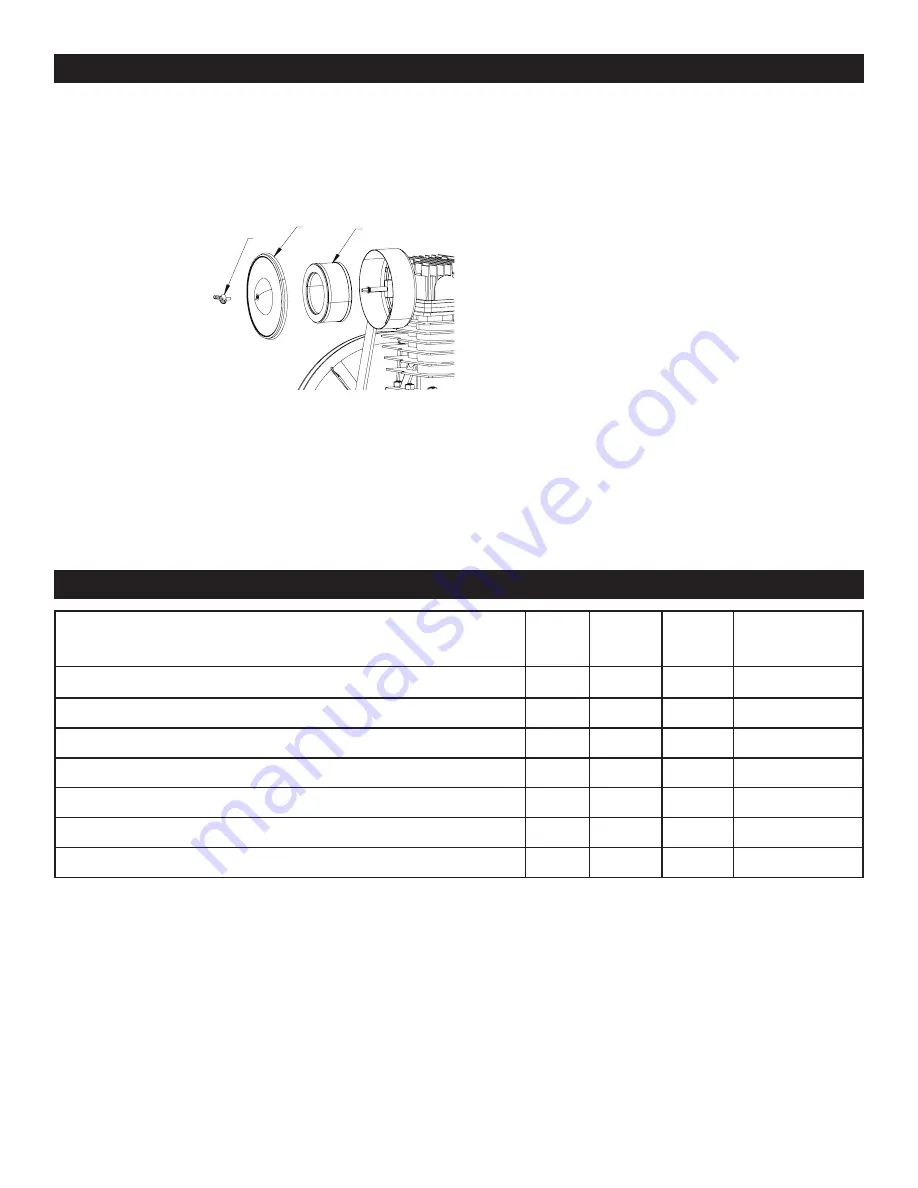

CLEANING THE AIR FILTERS

CHECKING THE RELIEF VALVE

TESTING FOR LEAKS

STORAGE

A

B

C

A = Wing nut(s)

B = Metal cover(s)

C = Filter element(s)

Summary of Contents for IV5076055

Page 35: ...200 2927 35 200 2927 NOTES...