4

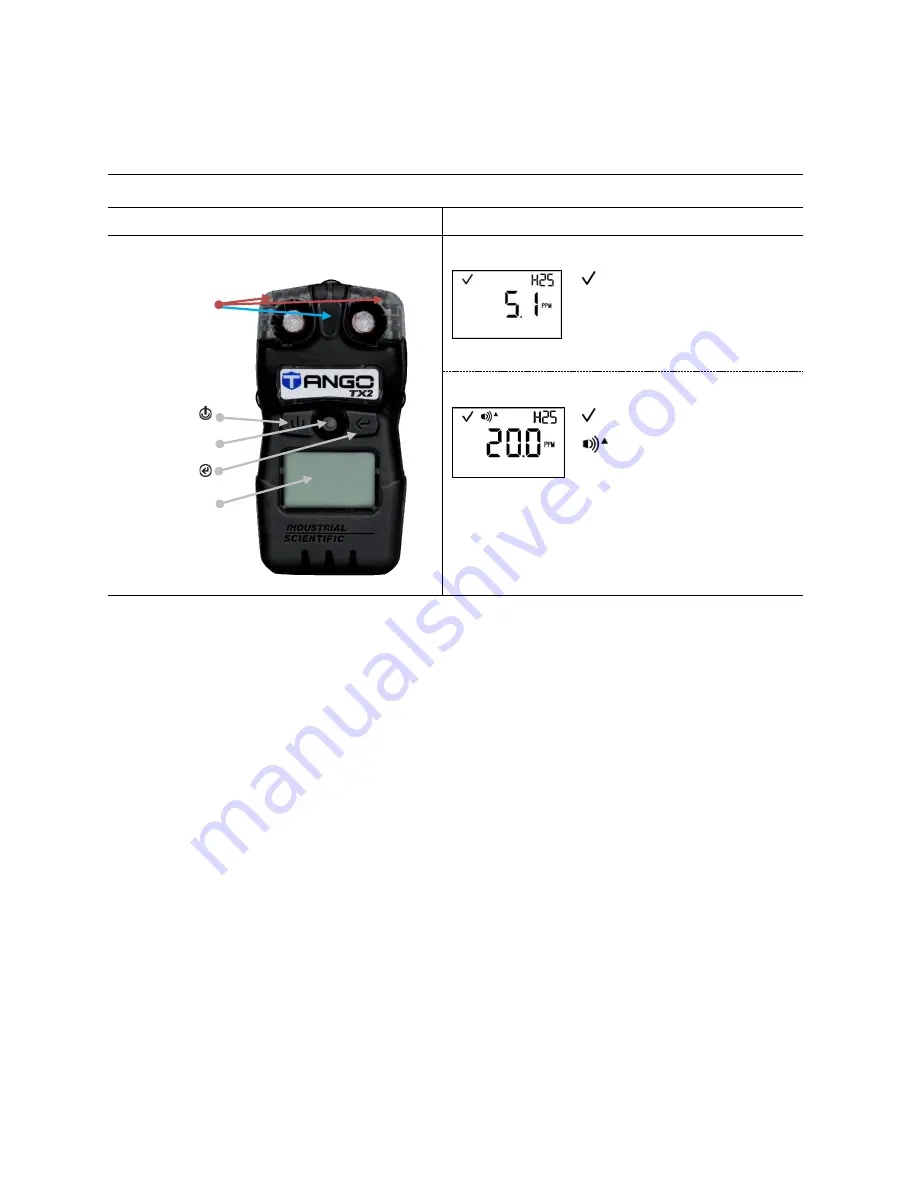

appear during operation. Likewise, the alarm-screen example shows how the display generally appears

when a gas event has caused an instrument alarm; sound, light, and vibration signals would also occur

based on the alarm type and some settings.

Figure 2.1 User interface

Instrument

Display screen (samples)

Home screen

Operating

Lights

H2S

Gas sensor

5.1 PPM

Gas reading and unit of

measure

Alarm screen

Power button

Operating

Speaker

High alarm

Enter button

H2S

Alarm-causing gas sensor

Display screen

20.0

PPM

Gas reading and unit of

measure

Vibration

(not

shown)

Gas-reading display behavior

The safety team sets how the instrument

—

when

not

in alarm

—

will display gas readings. As noted in the

setting,

“

Gas reading display

”

, the options are:

•

Display readings only for sensor 1.

•

Display readings only for sensor 2.

•

Alternately display readings for one sensor, then the other using a 3-second interval.

When a gas sensor causes an instrument alarm, the instrument will automatically display gas readings

using the alternating pattern. When the alarm-causing condition is no longer detected, the readings display

will revert to its set behavior.

Preparing the Tango TX2 for First Use

There are three steps to prepare the Tango TX2 for first use.

1.

Review instrument settings and adjust as needed. See the chapter,

2.

Calibrate the instrument. See the chapter,

3.

Perform a bump test. See the chapter,

Summary of Contents for TANGO TX2

Page 6: ......

Page 16: ......

Page 38: ...32 Illustration 7 1 Disassembled Tango TX2 and case top assembly Instrument Case top assembly...