INSTRUCTION

i

Read this instruction before installation

and wiring of the product

Instruction TPDAxxxxAx

1

TPDAxxxxAx

Pressure transmitter

TPDA...A are single or dual port pressure transmitters with one or two

universal outputs for 0...10 V or 4...20 mA (selectable).

Technical data

Supply voltage

24 V AC/DC ±15 %

Protection class

IP54

Calculated power consumption

0...10 V mode

2 VA (rms) / min. trafo size 7.5 VA

4...20 mA mode

2.7 VA (rms) / min. trafo size 9 VA

Overall accuracy, pressure

≤ 1 % full scale

Annual deviation (typical)

P1250 models

±2 Pa

P2500 models

±4 Pa

P7500 models

±20 Pa

Damping (settable)

1, 2, 4 and 8 s

Operating temperature range -25…+50°C

Operating humidity

Max. 95 % RH (non-condensing)

Overvoltage on any terminal

Max. ±18 V (referenced to GND)

Universal outputs PS1, PS2

Configured as 0...10 V

Load impedance ≥ 10 kΩ,

Output impedance ≤ 35Ω

Configured as 4...20 mA

Output is actively sourced into a resistive

load impedance to signal ground. The

load impedance must be between

40...500Ω

Pressure ranges (full scale)

Model

Pressure

range (Pa)

mBar

mmH

2

O

inH

2

O

TPDA-12A

PS1

0…1250

0…12.5

0…125

0…5

TPDA-25A

PS1

0…2500

0…25

0…250

0…10

TPDA-75A

PS1

0…7500

0…75

0…750

0…30

TPDA-1225A2

PS1

0…1250

0…12.5

0…125

0…5

PS2

0…2500

0…25

0…250

0…10

TPDA-1275A2

PS1

0…1250

0…12.5

0…125

0…5

PS2

0…7500

0…75

0…750

0…30

Note:

The suffix in the name denotes the number of sensors in the unit.

The suffix “-2” indicates two sensors. No suffix means one sensor only.

Installation

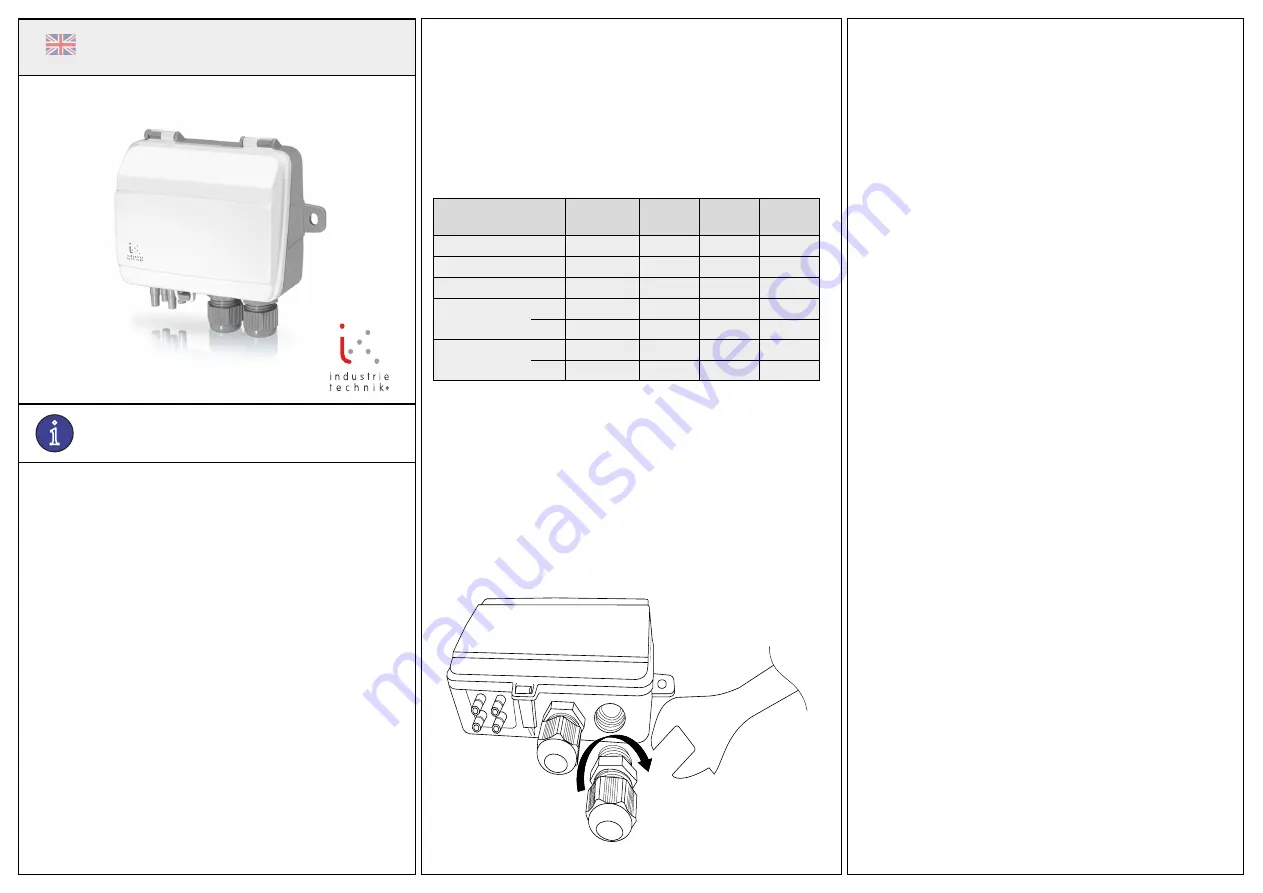

The transmitter comes with one cable gland mounted and one loose. If

two cables are used, one for supply voltage and one for output signals,

the other cable gland must be assembled to the housing. Screw in the

cable gland until the plastic knockout in the housing snaps. Make sure to

remove the plastic knockout completely. Secure the cable gland.

1. Mount the transmitter horizontally or vertically on a stable,

vibration-free surface. If the unit is installed in a humid environ-

ment, install it vertically with the cable gland edge of the unit

pointing down to allow moisture to escape.

Take extra care when connecting the hoses to the inlet ports, as

the thin inner connections of the inlets are very sensitive. The lid

should be kept closed while performing the connections, or the

thin tubing might detach from the sensor.

2. Refer to the graphics below for wiring. Use the leftmost cable

gland for supply voltage and use the rightmost gland for output

signals in order to minimise crosstalk between supply wires and

signal wires.

3.

Set the DIP-switch to the desired operational mode and param-

eters.

4. Power up the unit.

5.

Let the unit warm up for 10 minutes, then perform a zero-set

calibration by pressing the pushbutton.

6. Connect plastic tubes from the ventilation duct to the pressure

inlets.

NOTE: A straight cut off nipple must be used for mounting in the

ventilation duct.

For optimal measuring results, measuring points with turbulent air

flow should be avoided. Preferably, measuring should be performed

at a distance of 2 duct diameters before bends and branching and at

6 duct diameters after bends and branching.

Wiring

1. G (+)

2. G0 (-)

3. UO1 +

4. UOI GND

5. UO2 +

6. UO2 GND

Terminals 2, 4 and 6 are galvanically the same (GND/G0).

For models with two sensors, the leftmost DIP-switch controls sensor

1 and the rightmost DIP-switch controls sensor 2 (see diagram 2

below).

12632 C

JUL

17

EN