P. I. E. INEL Sp. z o. o., ul. Mostowa 1, 80-778 Gdańsk, inel@inel.gda.pl www.inel.gda.pl

5. OBSTACLE DETECTION OPERATING PRINCIPLE

Before limit positions are set (factory mode), the motor will

only detect decreased rpm caused by overload. The

obstacle detection function will be activated only after both

limit positions are set.

Obstacle detection works only for downward movement.

During upward movement, the drive will stop if decreased

rpm are detected.

If the roller blind stops unexpectedly (an obstacle appears),

the drive will move in the opposite direction in order to

release curtain tension, allowing you to remove the obstacle.

6. TROUBLESHOOTING

Problem:

The motor does not react to commands

Cause:

Thermal cut-out was activated

Solution:

Wait for 10-20 minutes

Problem:

Curtain fins do not close fully

Cause:

The curtain is blocked in the guides

Solution:

Check the roller blind guides and curtain slats

Problem:

The motor stops on its own

Cause:

The curtain is blocked in the guides

Solution:

Check the roller blind guides and curtain slats

Problem:

Blocking hangers were not detected

in semi-automatic programming

Cause:

Roller blind curtain too long.

Solution:

Shorten the curtain to appropriate size.

Problem:

The motor does not detect obstacles when

moving down.

Cause:

Limits programmed wrong way.

Solution:

Reset the drive to factory mode, then repeat the

programming procedure, starting from the upper

limit.

WARNING! Pauses between individual presses of the blind

switch buttons should be at least 1 second long! This applies

both

to

the

programming

and operating mode (after programming limit positions).

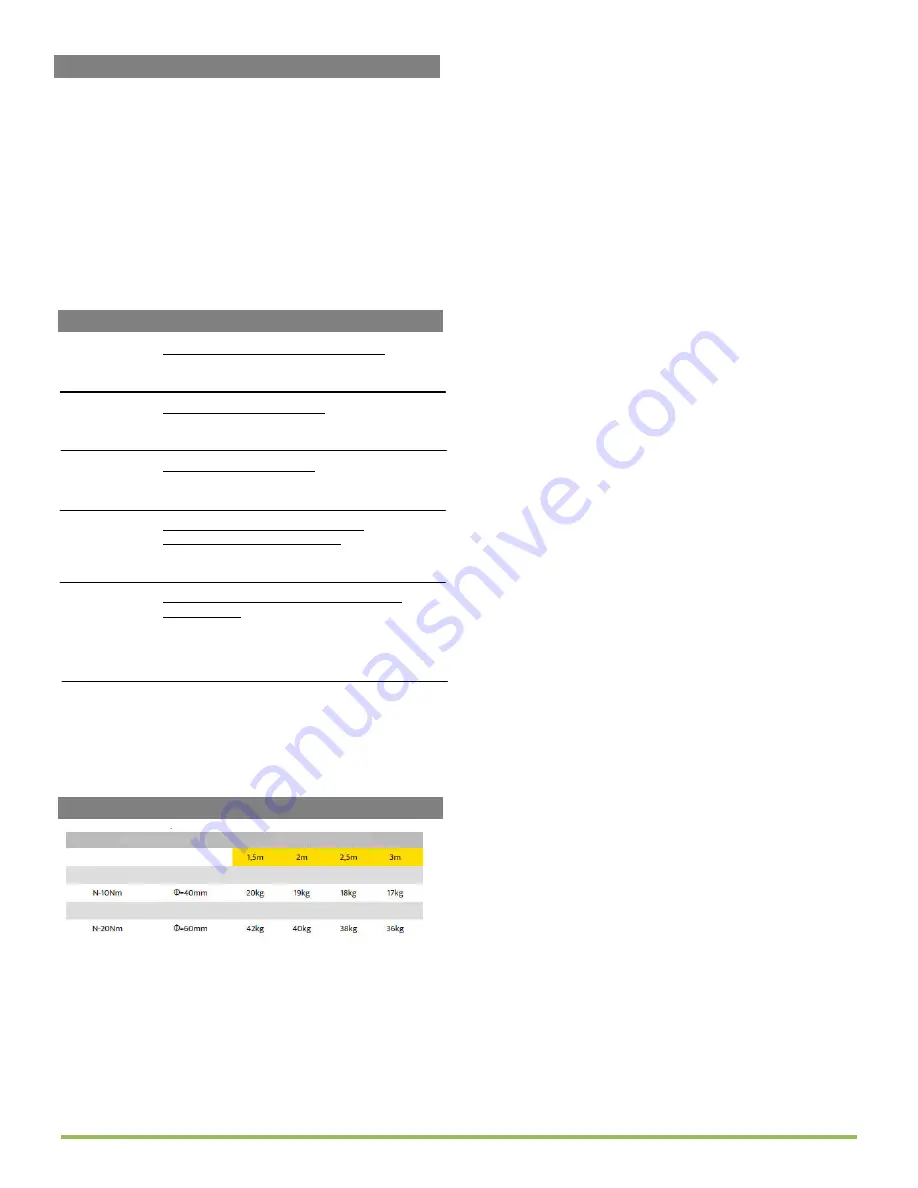

7. MOTOR SELECTION TABLE

TORQUE

ROLLER BLIND LENGTH