SAFETY INFORMATION

Warning

Any person performing service of this unit will be exposed to

hazardous voltages and the risk of electric shock. It is

assumed that any person who removes the amplifier from this

cabinet has been properly trained in protecting against

avoidable injury and shock. Therefore, any service

procedures are to be performed by qualified service personal

ONLY!

Caution

This unit does not have a power switch. Hazardous voltages

are present within the unit whenever it is plugged in.

Before the amplifier is plugged in, be sure its rated voltage

corresponds to the voltage of the AC power source to be

used. Incorrect voltage could cause damage to the amplifier

when the AC power cord is plugged in. Do not exceed rated

voltage by more than 10%: operation below 90% of rated

voltage will cause poor performance or may shut the unit off.

List of Safety Components Requiring

Exact Replacements

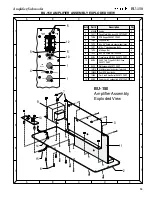

F1

Fuse SLO BLO 1.5A 250V 20mm.

UL approved

PWRCORD SPT-2 or better with polarized plug, UL

approved wired with the hot side to fused side.

Use with factory replacement panel strain relief

only.

T1

Transformer. Use only factory replacement.

DBR

Bridge diode. Use only factory replacement.

C1, 2

2200uF, 100V electrolytic filter caps. Be sure

replacement part is at least the same working

voltage and capacitance rating. Also the lead

spacing is important. Incorrect spacing may

cause premature failure due to internal cabinet

pressure and vibration.

C6

4.7uF 100V electrolytic radial

S64AMI

Power output module. Use only factory

replacement

Faceplate

Faceplate. Use only factory replacement

Air leak cover Use only factory replacement

CMC1

Use only factory replacement

L1

Use only factory replacement

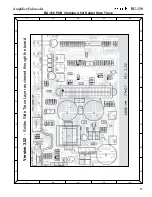

Fuse PCB

Use only factory replacement

Main PCB

Use only factory replacement

Leakage/Resistance Check

Before returning the unit to the customer, perform a leakage

or resistance test as follows:

Leakage Current. Note there is no power switch on this unit.

When the power plug is plugged in, the unit is live. Connect

the unit to its rated power source. Using an ammeter,

measure the current between the neutral side of the AC

supply and chassis ground of the unit under test. if leakage

current exceeds 0.5mA, the unit is defective. Reverse the

polarity of the AC supply and repeat.

Resistance. Measure the resistance from either side of the

line cord to chassis ground. If it is less than 500k ohms, the

unit is defective.

WARNING! DO NOT

return the unit to the customer if it fails

one of these tests until the problem is located and corrected.

2

Amplifier/Subwoofer

BU-150