2 1

Amplifier/Subwoofer

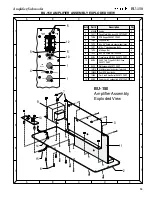

BU-150

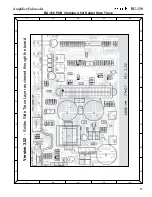

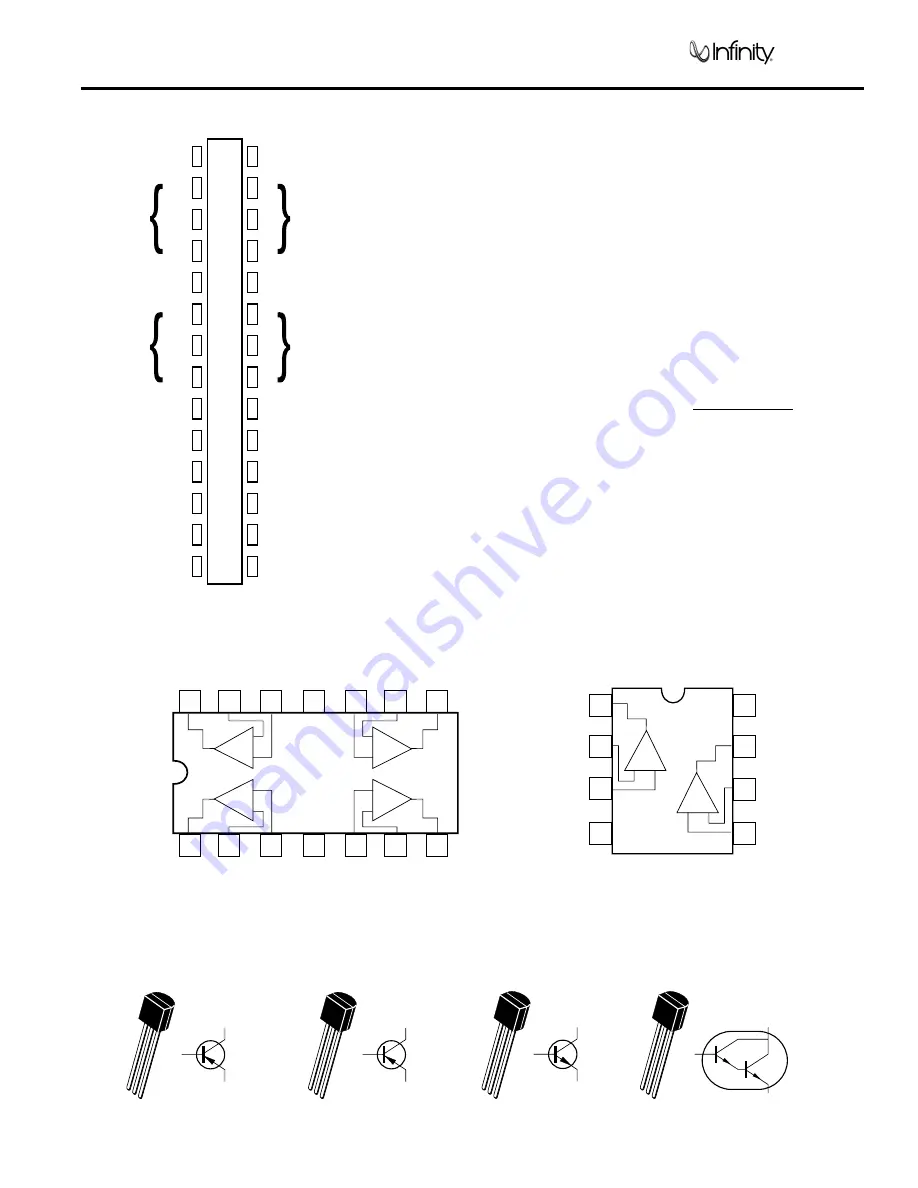

BU-150 INTEGRATED CIRCUIT DIAGRAMS

U1 - (

LM324) Quad Op Amp

U2 -

(TLO 82) Dual Op Amp

1

5

2

6

3

7

4

14

10

13

9

12

8

11

1

2

4

3

-

-

-

-

+

+

+

+

OUT 4

OUT 1

IN 4-

IN 1-

IN 4+

IN 1+

GND

V+

IN 3+

IN 2+

IN 3-

IN 2-

OUT 3

OUT 2

2

Base

2

Base

3 Collector

3 Collector

1 Emitter

1 Emitter

1

1

2

2

3

3

Q4, 5

- (MPS A56)

80V PNP Transistor

Q2

- (2N3906)

40V PNP Transistor

2

Base

2

Base

3 Collector

3 Collector

1 Emitter

1 Emitter

1

1

2

2

3

3

Q3

- (2N3904)

40V NPN Transistor

Q1

- (MPS A13)

30V NPN(Darl) Transistor

S53AMI/S64AMI

- Power Amp module SAFETY PART

15

16

17

18

19

20

21

22

23

24

25

26

27

28

1

2

3

4

5

6

7

8

9

10

11

12

13

14

+6V

v+

O/P

V-

+15V

SD

FR

I/P

GND

-15V

+6V

v+

O/P

V-

+15V

SD

FR

I/P

GND

-15V

NOTE:

THE FOLLOWING PROCEDURES MUST BE FOLLOWED

WHEN INSTALLING NEW S53AMI/S64AMI AMP MODULES:

FAILURE TO FOLLOW ONE OR MORE OF THESE STEPS MAY

RESULT IN THE INSTANT DESTRUCTION OF THE MODULE WHEN

POWERED UP.

Align white indent marker on Amp Module with indent marker on main

PCB; alternately observe position of label on the top of the module;

incorrectly replacing the Module 180 in the PCB slot will result in its

destruction.

All AC powered test instruments (meters, oscilloscopes, etc.) must

have a floating ground, i.e. be connected to an isolation transformer.

Align and position the Amp Module before soldering.

Attach the amp Module with the mounting screws

or

powering up.

Use only rosin-core or non-acid core solder; thoroughly de-flux the

surfaces after soldering.

If the new S53AMI/S64AMI Amp Module has larger mounting hole(s) in

the case, and the stock screws no longer will fit, and screws of the

proper type cannot be obtained locally order:

(2) part# 60301S (screws)

(2) part# 60301N (nuts)

°

before soldering

1)

2)

3)

4)

5)

1

2

3

4

8

7

6

5

A

B

-

-

+

+

B OUTPUT

A OUTPUT

B -INPUT

A -INPUT

B +INPUT

A +INPUT

V

-

V

+