HQ Infinity Service Manual

| 27

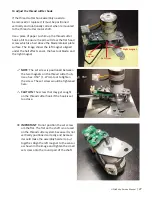

To adjust the thread cuttter hook

If the thread cutter hook assembly needs to

be removed or replaced, it must be positioned

vertically and rotationally correct when remounted

to the thread cutter motor shaft.

Use a piece of paper to shim up the thread cutter

hook a bit to ensure the arm will clear the flat head

screw which is a hair above the blade retainer plate

surface. The image shows the left magnet aligned

under the hall effect sensor, the hex tool blade, and

the right magnet.

NOTE

: The set screw is positioned between

the two magnets on the thread cutter hub.

Use a hex .050" / 1.27mm tool to tighten

the screw. The set screw would be tightened

here.

U

CAUTION

: The screw that may get caught

on the thread cutter hook if the hook is set

too close.

Â

IMPORTANT

: Do not position the set screw

om the flat. The flat on the shaft is not used

on the thread cutter system because it is not

vertically positioned correctly and because

it would make the assembly harder to put

together. Align the left magnet to the sensor

as shown in the image and tighten the small

set screw onto the round part of the shaft.

Left

magnet

Right magnet

Set screw