36 |

www.HandiQuilter.com

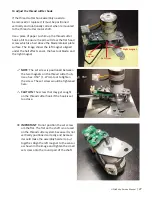

To correct the rear hook shaft

1.

Use a 2mm hex tool to loosen the two sets screws on the front pulley and slide the front pulley

and spacer up against the front bearing internal race. (Ensure the bearing is firmlly seated into its

housing.)

2.

Firmly retighten the first screw in direction of motion onto the flat of the hook shaft. (Ensure the

bearing is firmlly seated into its housing.)

3.

Firmly retighten the second screw in direction of motion onto the shaft.

4. Use a 2mm hex tool to loosen the two set screws on the back pulley and slide the back pulley and

spacer up against the back bearing internal race. (Ensure the bearing is seated firmly into its housing.)

5.

Firmly retighten the first screw in direction of motion onto the flat of the hook shaft.

6.

Firmly retighten the second screw in direction of motion onto the shaft.

7. Check the hook shaft for any play front to back by pushing the shaft front to back in the bottom frame

extrusion.

Main Shaft

(long top shaft with hand wheel)

The main shaft has two ball bearings in the rear frame bulkhead that are pressed onto the main shaft

with the rear frame bulkhead. The main shaft timing pulley by the hand wheel is stepped down on the

front edge to ride against the back bearing inner race and will help hold the ball bearings into the rear

frame bulkhead. This keeps the main shaft from being able to shift forward.

The main shaft encoder with its flange to the back is next, just inside the rear frame bulkhead. It has to

be placed on the shaft before the rear bulkhead and bearings are pressed onto the main shaft.

The main shaft also has a ball bearing in a mount that is pressed on the shaft in the middle part of the

shaft. This bearing and mount align with the mounting holes in the upper main extrusion.

The front of the main shaft has three additional bearings that support the main shaft; two bearings are

in front of the pulley and one behind. The very front end of the main shaft is stepped down to fit these

front three bearings and the counterweight crank.

The two front-most bearings on the main shaft are positioned onto the shaft so they press up tight

against a flange at the front of the gear box in the head frame. Directly behind them is a pulley with a

wide belt and behind the pulley there is one more ball bearing which is held into place at the rear with a

snap ring in the head frame. The top pulley on the main shaft drives the pulley on the bottom short shaft.

The bottom pulley on the short shaft drives the pitman, needle bar, and hopping foot.