0B

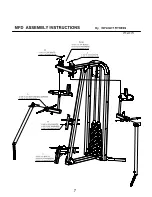

MFD ASSEMBLY INSTRUCTIONS

1B

MAIN STRUCTURE ASSEMBLY

A.

Attach Loop Upright, Base Tube, and Stabilizer using 4 – 3/8” x 8 ½” bolts, 4

– curved 3/8” washers, 4 – 3/8” flat washers and 4 - 3/8” nuts.

B.

Attach Main Upright to Base Tube using one L/H Corner Bracket and one R/H

Corner Bracket and 3 – 3/8” x 5 ½” bolts, 6 – 3/8” flat washers and 3 – 3/8”

nuts.

C.

Attach Top Beam to Loop Upright using 2 – 3/8” x 2 ¾” bolts and 2 3/8” flat

washers (no nuts).

D.

Attach the Top Beam to the Main Upright using one L/H Corner Bracket and

one R/H Corner Bracket and 3 – 3/8” x 5 ½” bolts, 6 – 3/8” flat washers and 3

– 3/8” nuts.

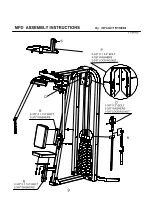

WEIGHT STACK ASSEMBLY

E.

Insert Guide Rods into the base of the Loop Upright. Allow Guide Rods to

lean back towards stabilizer.

Place one weight stack cushion on each Guide Rod and slide down to the

base.

Apply lubricant to the Guide Rods from the weight stack cushions to the tops

of the Guide Rods.

Making sure that the recess for the weight labels is facing towards the

machine and that the three pads are facing down slide onto the Guide Rods:

5 – 15lb. Weights, 10 – 10lb. Weights and 5 – 5lb. Weights.

Place Top Weight on the Guide Rods with the drilled hole facing the machine

and slide down to the stack.

F.

Install Upper Pulley Bracket by placing the pins into the tops of the Guide

Rods. Stand weight stack up right and fasten Upper Pulley Bracket to the

Loop Upright and Top Beam using the 2 – 3/8” x 2 ¾” bolts and 2 – 3/8” flat

washers installed in Step

C.

4