SMT-BD2

3.2

–

X1

CONNECTOR FOR

TTL

INCREMENTAL ENCODER

&

HES

CONFIGURATION

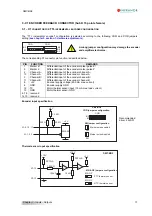

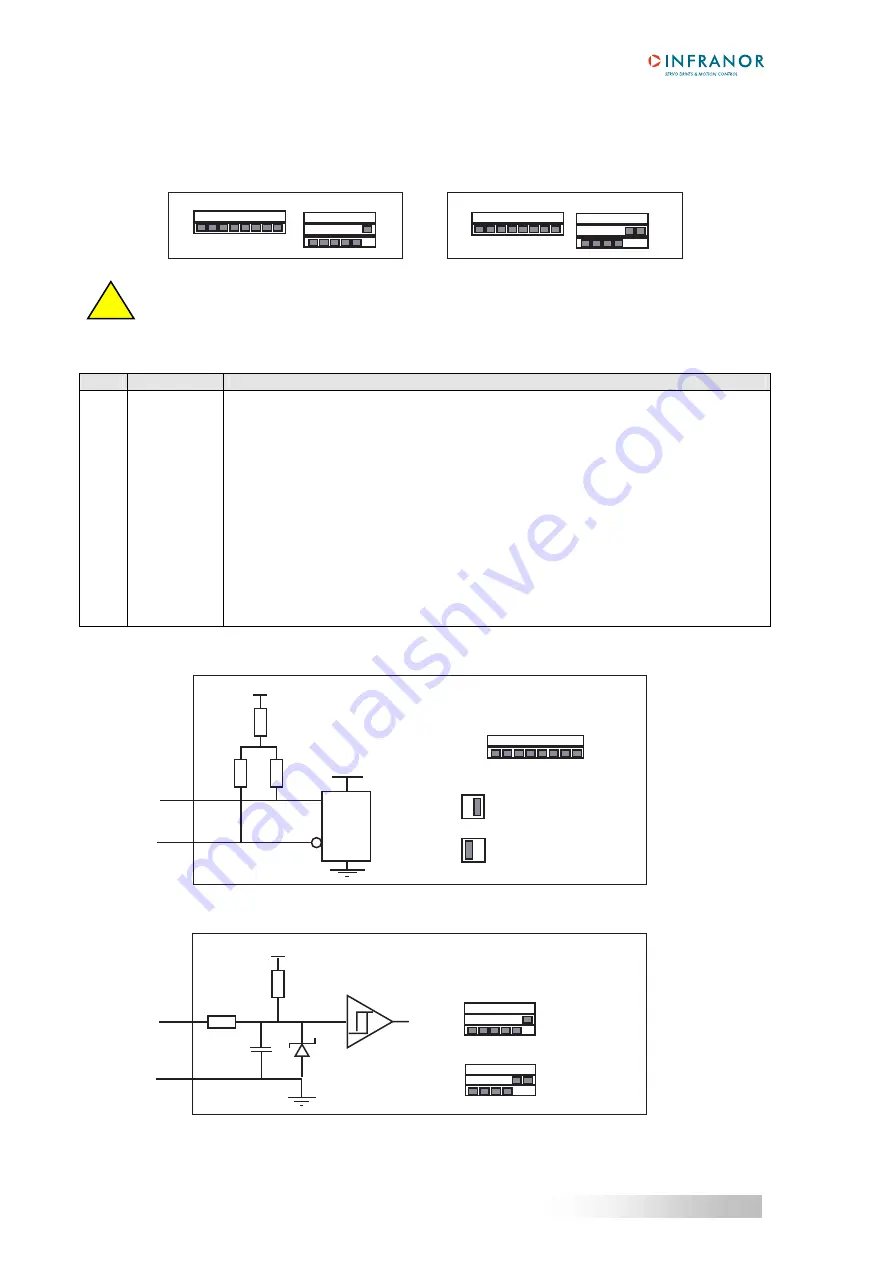

The “ TTL incremental encoder & HES” configuration is selected according to the following COM and COD

jumpers setting (

see chapter 5, section 1: Hardware adjustments

).

COD

B5

B4

B2

B1

COM

B3

COD

B5

B4

B2

B1

COM

B3

60

°

HES type

120

°

HES type

!

A wrong jumper configuration may damage the encoder and amplifier electronics.

The corresponding X1 connector pin function is described below.

PIN

FUNCTION

REMARKS

1

Marker Z/

Differential input of the encoder marker pulse Z/

9

Marker Z

Differential input of the encoder marker pulse Z

2

Channel A/

Differential input of the encoder channel A/

10

Channel A

Differential input of the encoder channel A

3

Channel B/

Differential input of the encoder channel B/

11

Channel B

Differential input of the encoder channel B

5

+5V

Encoder supply voltage (400 mA max. current)

4

GND

Encoder supply GND

14

HALL U

Hall sensor input signal phase U

6

HALL V

Hall sensor input signal phase V

7

HALL W

Hall sensor input signal phase W

15

+15V

Hall sensors supply voltage (50 mA max. current)

12

TC

Motor thermal sensor input (10 mA max. load current)

13

GND

Hall sensors/Thermal sensor GND

8 reserved

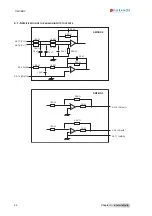

Encoder input specification

+5 V

+5 V

3,3 K

Ω

200

Ω

200

Ω

26LS32

X1-9, 10, 11

X1-1, 2,3

ZM

ZM

COD

B2

B1

SMT-BD2

Marker pulse enabled

Marker pulse disabled

ZM jumper configuration

COD jumpers configuration

Recommended

driver: 26LS31

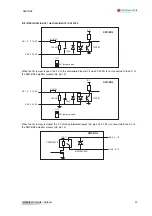

Specification of the Hall sensors input

+5 V

10 K

Ω

X1-6, 7, 14

X1-13

COM

COM

SMT-BD2

1 K

Ω

B5

B4

B3

B5

B4

B3

60

°

HES

120

°

HES

74HC14

1 nF

COM jumpers configuration

18

Chapter 3 – Inputs-outputs