SMT-BD2

2 - WIRING (according to CEI 801 and EN 55011 standards)

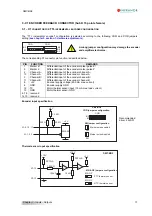

2.1

-

GND

WIRING AND GROUNDING

The reference potential is the

earth (ground)

. Motors and sensors (e HES) are grounded via their

housing. If a potential reference is existing, like a main chassis or a cabinet, with a low impedance between the

various elements, it should be used to connect ALL references to it and also connect this reference to the earth

(ground).

Long reference potential connections are suitable

ONLY

if these connections have an impedance < 0,1

Ω

. Cables

with low potential should

NEVER

run in the proximity of power lines.

Each conductor cable

(carrying a potential)

must be

shielded

. Several wires in the

same sleeve

must be

twisted

and

shielded

.

According to the

CEI 801 standard

, the connectors must be metallic or metal plated and must have

a 360° shield

connection

.

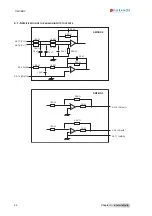

2.2

-

M

OTOR AND SENSORS CABLES

Cable ends should have a metallic collar allowing a 360° shield connection.

Motor cables must be shielded to avoid common mode effects.

Encoder and HES cable must also be shielded.

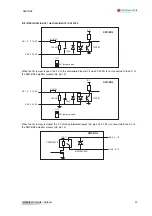

2.3

-

I

NPUT COMMAND AND SERIAL LINK CABLES

The analog input command signal CV requires a pair twisted and shielded cable. The shield must have a "360°"

connection via metallic collars at both ends. If the shield is connected by means of a pig tail, it must be connected

at one end to a 0 Volt pin of X4 on the amplifier side with a connection as short as possible.

The input command (CV) wiring must be made according to the polarity between the controller and the amplifier

(CV on "diff high" of the controller). The logic 0 Volt is directly connected to the amplifier housing. The connection

continuity is ensured by the fastening screws on the front panels.

The amplifier 0 Volt and the controller 0 Volt

MUST be connected by means of a wire. The shield MUST NEVER be used as a conductor of the 0 Volt

potential

.

The serial link cable must also be shielded according to the above mentioned shielding recommendations.

28

Chapter 4 – Connections