Triton Go Product Manual |

Product Description

INGENIA | 05/29/2017

17

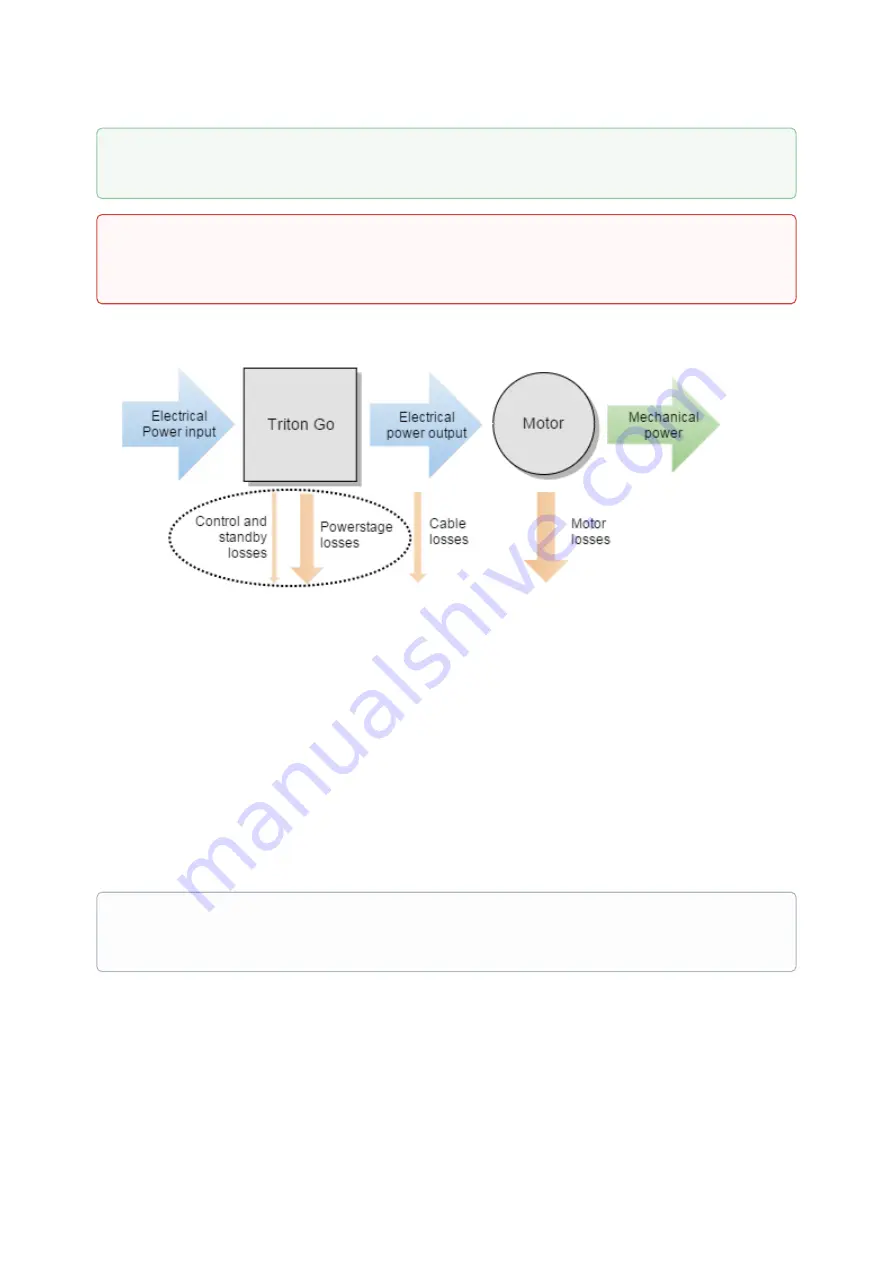

Following figure shows the basic power flow and losses in a servo drive system.

4.4.1 Power losses calculation (heat dissipation)

Current flowing through Triton Servo Drive causes power losses that, ultimately, are converted in heat. This

heat must be transferred to its surrounding environment efficiently, so that the temperature of the drive does

not reach dangerous levels. The greater the power losses, the more effective the heat dissipation must be.

Power losses mainly depend mainly on 3 parameters:

•

Motor RMS current

: this is the cause of what are called

static

or

conduction

power losses, which

typically are the main source of power losses, having that they show a positive correlation in a squared

ratio.

•

DC bus voltage

: this, along with the motor RMS current and PWM switching frequency, is the cause of

what are called

dynamic

or

commutation

losses, and show positive correlation in a proportional ratio.

•

PWM switching frequency:

similar to DC bus voltage, the PWM switching frequency directly affects the

commutation losses. Typically, 20 kHz is the default value, but it can be increased up to 80 kHz.

Other less relevant parameters affect also the power losses but are not considered in the following graphs:

• Air temperature: higher power semiconductor temperatures reduce their efficiency.

•

Motor speed: faster motor speeds result in higher overall power losses since the input DC bus current is

greater, and this increases conduction losses on the reverse polarity protection circuitry.

Drive safety is always ensured by its protections. However, by means of it, power losses and

temperature will limit the allowable motor current.

Some parts of the Triton Go can exceed 110 ºC during operation, especially at high load levels.

Do not touch the Triton Go during operation

and wait at least 5 minutes after turn off to allow a safe

cool down.

PWM switching frequency and nominal specifications

All nominal specifications in this manual are measured under a PWM switching frequency of 20 kHz.