SPECIFICATIONS

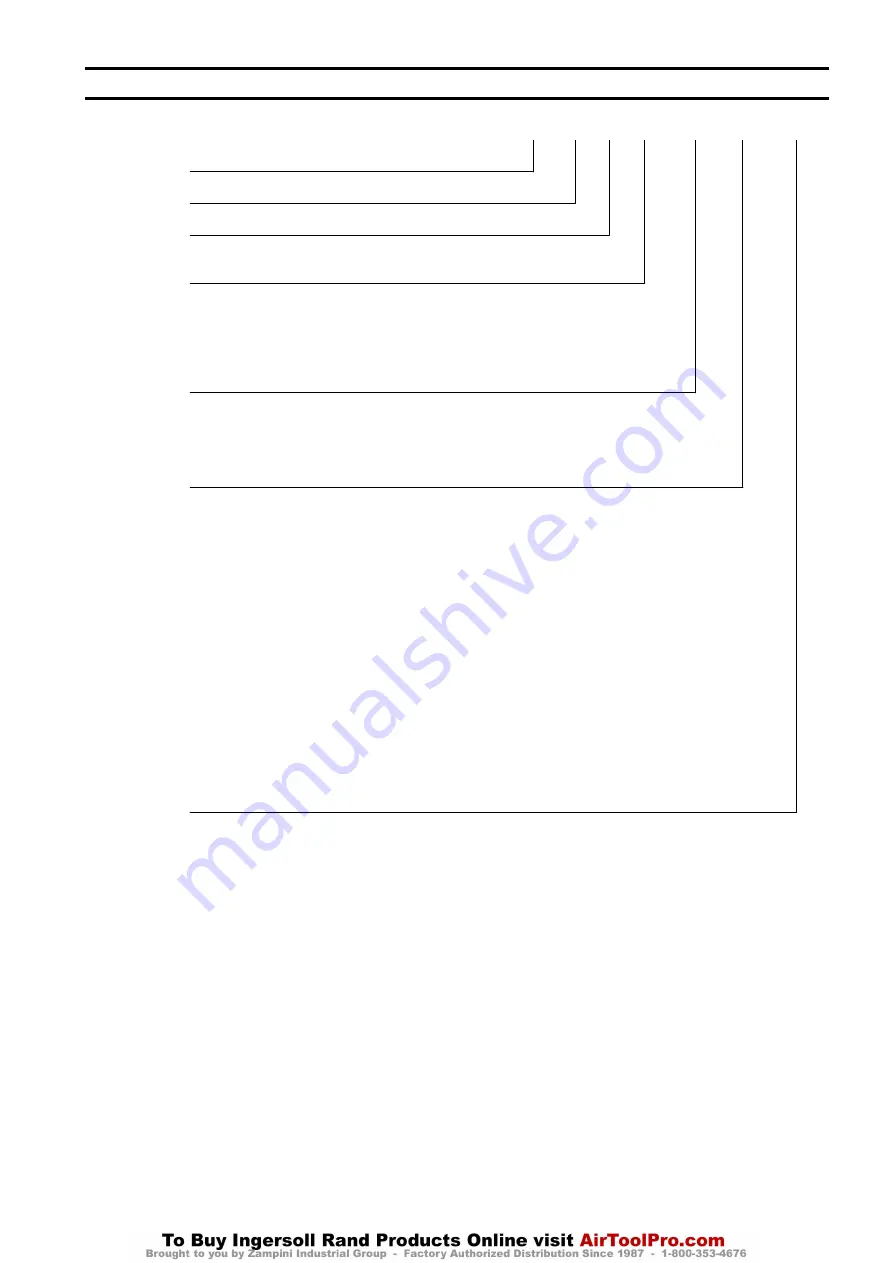

Model Code Explanation:

Example: FA150KGiMR12–1–C-E

FA

150KGi

MR

12

-

1

-

C

-

E

Series:

FA

= Force 5 Infinity Air Powered

Capacity (based on wire rope at full drum):

150KGi

= 330 lb [150 kg] Man Rider Rating

Man Rider

Designation:

MR

= Man Rider

Drum Length:

8

= 8 inches (203 mm)

12

= 12 inches (305 mm) (standard)

16

= 16 inches (406 mm)

24

= 24 inches (610 mm)

Drum Brake:

Manual Drum Band Brake Standard

A

= Automatic drum band brake

Control:

1

= Winch mounted lever throttle (Standard)

3XX

= Remote control (Contact factory) †

Wire Rope Take-off Range:

0°- 90°

Wire rope take-off angle (standard).

Contact factory for non-standard wire rope angles.

Design Temperature:

Blank

= 0° C (32° F) or warmer

C

= -20° C (-4° F)

Options:

7

= Grooved drum (Wire rope sizes in sixteenths, e.g. 7/16 in)

B

= Winch mounted base

E

= Emergency lowering system

F

= Air Line Accessories (mounted on front or back of winch guard panel)

H

= Stainless Steel Hoses (rubber hose is standard)

J

= Air Line Accessories

K

= Stowage valve

M1

= Typical Material Certificates (2.2) *

M2

= As-received traceability *

M3

= As-shipped traceability *

N1

= Type approval – ABS ††

N2

= Type approval – DNV ††

Q

= Special Paint ††

W1

= ABS – witness testing ††

W2

= DNV – witness testing ††

W3

= LRS – witness testing ††

W4

= Customer witness testing ††

X

= Testing ††

-E

=

Compliance with EU Machinery Directive, refer to “DECLARATION OF CONFORMITY” on page 15 (Includes emergency stop and overload

protection)

Notes:

* Refer to ‘Traceability’ on page 4 for a description of the differences between M1, M2 and M3.

† Not covered in this manual.

†† If N, Q, W or X are entered, the details must be specified in the text of the sales order.

Form MHD56314 Edition 4

3