25

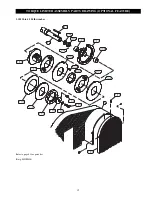

General Disassembly

The following instructions provide the necessary information to

disassemble, inspect, repair, and assemble the winch. An

exploded drawing of the winch is provided in the Parts Section

to assist part identification. If a winch is being completely

disassembled for any reason, follow the order of the topics as

they are presented. It is recommended that all maintenance work

on the winch be performed in a clean dust free work area.

In the process of disassembling the winch, observe the

following:

1.

Never disassemble the winch any further than is necessary

to accomplish the needed repair. A good part can be

damaged during the course of disassembly.

2.

Never use excessive force when removing parts. Tapping

gently around the perimeter of a part with a soft hammer

should be sufficient to loosen the part.

3.

Do not heat a part with a flame to free it for removal, unless

the part being heated is already worn or damaged beyond

repair and no additional damage will occur to other parts.

In general, the winch is designed to permit easy disassembly and

assembly. The use of heat or excessive force should not be

required.

4.

Keep the work area as clean as practical, to prevent dirt and

other foreign matter from getting into bearings or other

moving parts.

Winch Disassembly (chain driven winches)

Refer to Drawing MHP0255.

Disconnect all power to the winch before starting disassembly.

Remove wire rope and limit switches if equipped.

1.

Remove capscrews (15), screws (16), washers (18) and nuts

(24) and lift off guard (3).

2.

Remove chain (6).

3.

Loosen setscrews (32) and remove sprocket (5) and key

(31) from motor and reducer assembly output shaft.

4.

Remove capscrews (17), lockwashers (21), washers (12)

and nuts (22). Using an overhead hoist with sufficient

capacity to adequately support the weight of the motor and

reducer assembly remove the motor and reducer assembly

from frame (1).

5.

Remove capscrews (9) and lockwashers (25) and lift off

caps (8).

6.

Remove adjusting screws (11) and nuts (20) from frame (1).

7.

Support the drum (2) using an overhead hoist with

sufficient capacity to adequately handle the weight of the

drum. Remove nuts (19) and lockwashers (13). Pull

bearings (7) from drum spigots.

8.

Lift drum (2) from frame (1) and carefully set in an area

which will not cause damage to the sprocket teeth.

9.

Remove bolt locks (4) and capscrews (14) from frame (1).

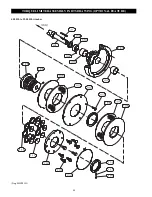

Winch Disassembly

15,000 - 25,000 lb winches

Refer to Drawings MHP0255 and MHP0278.

1.

Remove capscrews (15), screws (16), washers (18) and nuts

(24) and lift off guard (3).

2.

Remove chain (6).

3.

Loosen setscrews (32) and remove sprocket (5) and key

(31) from motor and reducer assembly output shaft.

4.

Remove capscrews (45), lockwashers (46) and nuts (47)

from bearing (40).

5.

Remove capscrews (17), lockwashers (21), washers (12) and

nuts (22). Using an overhead hoist with sufficient capacity to

adequately support the weight of the motor and reducer

assembly remove the motor and reducer assembly from frame

(1). Slide bearing (40) from motor and reducer assembly.

6.

Remove adjusting screws (11) and nuts (20) from frame (1).

7.

Remove capscrews (41), washers (42), lockwashers (48)

and nuts (43) from bearings (39).

8.

Lift drum (2) from frame (1) and carefully set in an area

which will not cause damage to the sprocket teeth. Pull

bearings (39) from drum spigots.

Winch Disassembly (direct drive winches)

Refer to Drawing MHP0260.

1.

Remove nuts (60) and lockwashers (59). Pull bearing (58)

from drum hub.

2.

Remove nuts (53), lockwashers (54) and capscrews (56)

from motor and frame (50).

3.

Slide the motor and drum assembly away from bearing (58)

until drum spigot is clear of the frame (50).

4.

Remove drum (51) from reducer assembly drive shaft.

Limit Switch Disassembly (optional feature)

Refer to Drawings MHP0263 and MHP0579.

1.

Remove screws (74) and lockwashers (73). Lift limit switch

(72) from bracket (71).

2.

Remove nuts (19) and lockwashers (13) from extension

studs (70). Remove bracket (71) and extension studs (70).

3.

Tap pin (75) out of drum only if it requires replacement.

On 15000B20 and 25000B25 winches, bracket (71) can only be

removed after capscrews (41), washers (42), lockwashers (48)

and nuts (43), that retain bearing (39), have been removed.

Cleaning, Inspection and Repair

Use the following procedures to clean, inspect, and repair the

components of the winch.

Cleaning

Clean all winch component parts in solvent. The use of a stiff

bristle brush will facilitate the removal of accumulated dirt and

sediments on the sprockets, frame and drum. Dry each part using

low pressure, filtered compressed air.

Inspection

All disassembled parts should be inspected to determine their

fitness for continued use. Pay particular attention to the

following:

1.

Inspect sprockets for worn, cracked, or broken teeth.

2.

Inspect all bearings for wear, scoring, or galling. Check for

freeness of rotation. Replace bearings if rotation is rough or

bearings are excessively worn.

3.

Inspect shafts for ridges caused by wear. If ridges caused

by wear are apparent on shafts, replace the shaft.

4.

Inspect all threaded items and replace those having

damaged threads.

5.

Check guard for damage and that it provides suitable

protection from the roller chain and sprockets.

6.

Inspect chain to ensure it is clean and free from rust. Refer

to “LUBRICATION” section for information on cleaning

and lubricating chain.

Summary of Contents for 10000B20

Page 13: ...12 DRUM SWITCH CONNECTION DIAGRAMS Dwg MHP0201...

Page 14: ...13 230 Volt Single Phase 60 Hz Dwg MHP0271 WIRING DIAGRAM...

Page 15: ...14 WIRING DIAGRAMS Dwg MHP1086...

Page 16: ...15 Dwg MHP1087 WIRING DIAGRAM 208 575 Volt Three Phase 50 or 60 Hz 22 Amp and smaller...

Page 17: ...16 WIRING DIAGRAM Dwg MHP1088 208 575 Volt Three Phase 50 or 60 Hz 22 Amp and larger...