26

14. Using a straight edge, position sprocket (5) so it aligns with

the sprocket on drum (2). Install setscrews (32) with

Loctite

®

609 or equivalent and tighten.

15. Install chain (6) and adjust to obtain the correct chain

tension. It may be necessary to use a chain half link (37).

16. Install guard (3) on frame (1) and secure with capscrews

(15). Also install screws (16), washers (18) and nuts (24)

which clamp the guard mesh to the inside of the frame (1).

17. Check all warning labels and tags are present and clearly

visible.

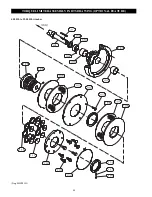

Winch Assembly

15,000 - 25,000 lb winches

Refer to Drawings MHP0255 and MHP0278.

1.

Position frame (1) on a flat and sturdy surface.

2.

Wipe clean and lightly lubricate bearing spigots on the

drum (2). Install one bearing (39) on each drum spigot.

3.

Using an overhead hoist with sufficient capacity to

adequately support the weight of the drum (2) position the

drum in frame (1). Ensure bearings (39) are located on the

bearing pads of the frame (1).

4.

Align the bearing (39) mounting holes with the bolt holes

in frame (1). Loosely install capscrews (41), washers (42),

lockwashers (48) and nuts (43).

5.

Loosely install adjusting screws (11) with nuts (20) in

frame (1).

6.

Install bearing (40) on reducer assembly output shaft. Using

an overhead hoist with sufficient capacity to adequately

support the weight of the motor and reducer assembly

position the motor and reducer assembly on frame (1).

Install capscrews (17), washers (12), lockwashers (21) and

nuts (22). Install capscrews (17) from underneath the frame

(1). Torque to specifications recommended in torque chart.

7.

Align holes in bearing (40) and frame (1) and install

capscrews (45), lockwashers (46) and nuts (47). Torque to

specifications recommended in torque chart.

8.

Install key (31) and sprocket (5) on output shaft of motor

and reducer assembly (26) or (27).

NOTICE

• Do not force sprocket onto output shaft by hammering.

Doing so may cause premature bearing failure.

9.

Using a straight edge, position sprocket (5) so it aligns with

the sprocket on drum (2). Install setscrews (32) with

Loctite

®

609 or equivalent and tighten.

10. Install chain (6) with master link (37) to obtain the correct

chain tension it may be necessary to use a chain half link (37).

11. Install guard (3) on frame (1) and secure with capscrews

(15). Also install screws (16), washers (18) and nuts (24)

which clamp the guard mesh to the inside of the frame (1).

12. Check all warning labels and tags are clearly visible.

Winch Assembly (direct drive winches)

Refer to Drawing MHP0260.

1.

Wipe clean and lightly lubricate spigots on the drum (51).

Install key (55) on reducer assembly drive shaft and

assemble drum (51).

2.

Install capscrews (57) and washers (61) in frame (50). Slide

motor and reducer assembly with drum into position.

Spigot of drum must pass through the frame upright.

3.

Install bearing (58) and secure in position with lockwashers

(59) and nuts (60).

4.

Install capscrews (56) from underneath frame (50). Install

nuts (53) and washers (54) on capscrews (56) and torque to

specifications.

Repair

Actual repairs are limited to the removal of small burrs and

other minor surface imperfections from sprockets and shafts.

Use a fine stone or emery cloth for this work.

1.

Worn or damaged parts must be replaced. Refer to the

applicable Parts Listing for specific replacement parts

information.

2.

Inspect all remaining parts for evidence of damage. Replace

or repair any part which is in questionable condition. The

cost of the part is often minor in comparison with the cost

of redoing the job.

3.

Smooth out all nicks, burrs, or galled spots on shafts, bores,

pins, or bearings.

4.

Examine all sprocket teeth carefully, and remove nicks or burrs.

5.

Polish the edges of all shaft shoulders to remove small

nicks which may have been caused during handling.

6.

Remove all nicks and burrs caused by lockwashers.

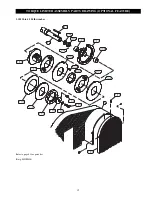

Winch Assembly (chain driven winches)

Refer to Drawing MHP0255.

1.

Position frame (1) on a flat and sturdy surface or

workbench.

2.

Wipe clean and lightly lubricate bearing spigots on the

drum (2). Install one bearing (7) on each drum spigot. The

flat mounting surface of each bearing (7) must be toward

the drum (2).

3.

Loosely install the bolt locks (4) in frame (1) so they are in

a vertical position and are located on the chain side of the

frame (1). Bolt locks (4) must be positioned with the

narrower edge located closest to the ‘U’ shaped cutout in

the frame (1).

4.

Loosely install capscrews (14) in frame (1) on the side

opposite the chain.

5.

Using an overhead hoist with sufficient capacity to

adequately support the weight of the drum (2) position the

drum in frame (1). Ensure that bearings (7) are located on

the outside of the frame drum support uprights and that the

bearing grease fittings are positioned at the bottom.

6.

Align the bearing mounting holes with bolts (14) or bolt

locks (4) and press into position.

7.

Install nuts (19) and lockwashers (13). Torque to

specifications recommended in torque chart.

8.

Loosely install adjusting screws (11) with nuts (20) in

frame (1).

9.

Install caps (8) on top of each frame (1) support. Check

threaded hole in cap is positioned nearest the drum (2).

10. Install capscrews (9) and lockwashers (25) to clamp caps

into position. Torque to specifications recommended in

torque chart.

11. Loosely install adjusting capscrews (10) with nuts (20) in

caps (8).

12. Using an overhead hoist with sufficient capacity to

adequately support the weight of the motor and reducer

assembly position the motor and reducer assembly on

frame (1). Install capscrews (17), washers (12),

lockwashers (21) and nuts (22). Install capscrews (17) from

underneath the frame (1). Torque to specifications

recommended in torque chart.

13. Install key (31) and sprocket (5) on output shaft of motor

and reducer assembly (26) or (27).

NOTICE

• Do not force sprocket onto output shaft by hammering.

Doing so may cause premature bearing failure.

Summary of Contents for 10000B20

Page 13: ...12 DRUM SWITCH CONNECTION DIAGRAMS Dwg MHP0201...

Page 14: ...13 230 Volt Single Phase 60 Hz Dwg MHP0271 WIRING DIAGRAM...

Page 15: ...14 WIRING DIAGRAMS Dwg MHP1086...

Page 16: ...15 Dwg MHP1087 WIRING DIAGRAM 208 575 Volt Three Phase 50 or 60 Hz 22 Amp and smaller...

Page 17: ...16 WIRING DIAGRAM Dwg MHP1088 208 575 Volt Three Phase 50 or 60 Hz 22 Amp and larger...