10.0 INSTALLATION AND INITIAL START-UP

10.1 EQUIPMENT APPLICATION GUIDELINES

Ingersoll Rand Regenerative air dryers are shipped complete with

desiccant up to and including model HB2100. On larger units, the

desiccant is packaged separately for ease in handling. Refer to Section

11.6 for desiccant fill procedures.

To achieve the best dryer performance, carefully check that the design

and installation requirements outlined below are satisfied.

Ingersoll Rand dryers are available with an operating range from 75 -

150 PSIG. Air available for your usage will vary with operating pressure.

The maximum design pressure of the standard Desiccant Dryers is 150

PSIG. For units that require higher operating pressures, consult your

Ingersoll Rand representative.

Dryers are sized according to flow and pressure drop, not pipe size. The

difference between the inlet and the outlet flow is the amount of purge

air required. This air is exhausted to atmosphere and is not available for

use downstream. Make certain air supply to dryer meets air demand

plus purge air requirements.

A

NOTICE

The standard dryer is not rated for any gas other than air.

A

NOTICE

Ingersoll Rand recommends that the mufflers be cleaned after initial start-

up to remove any desiccant dust generated during shipment. After running

dryer for initial 30 minute period, de-energize / depressurize dryer and

remove mufflers. Disassemble and clean the removable insert inside the

muffler core. Reinstall mufflers prior to operating dryer.

10.2 LOCATING AND MOUNTING

The dryer must never be installed where air and/or ambient temperature

exceeds 120°F or drops below +35°F. Locate dryer to avoid extremes

of heat and cold from ambient or other conditions. Where applicable,

dryer towers may be insulated to reduce heat loses. Avoid locating

dryer outside or where it is exposed to the elements.

The dryer, or any air system component, must be located to avoid

exposure to pulsation in the compressed air as well as possible surges

due to fluctuating demand. In addition, care must be used to minimize

exposure to vibration transmitted through mounting pads or piping.

Provide adequate space around the dryer for normal maintenance

requirements and service.

If the dryer is shipped with the desiccant packaged separately, install the

desiccant after locating and mounting. Desiccant has been provided

separately to minimize handling difficulty and placing unnecessary

stress on the dryer assembly.

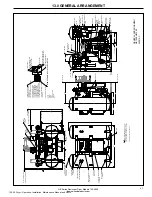

Bolt the dryer to the foundation using the bolt holes provided in the base

frame. Anchor bolts should project a minimum of 3.5 inches above the

foundation and allow proper nut and washer assembly.

10.3 PIPING

Pipe the compressed air lines to the inlet and outlet connections. Locate

the pre-filters as close as possible to the dryer. Ensure the positioning

allows for ease of servicing.

Note that the wet air inlet is located at the dryer's upper manifold and the

dry outlet air is located at dryer's lower manifold. In situations where air

supply is required 24- hours a day (it is undesirable to interrupt the airflow),

a three-valve bypass system is recommended to bypass the dryer. To

keep pressure drop at a minimum, use the fewest elbows necessary

Once all piping has been connected all joints, including those on the

dryer, should be soap bubble tested at line pressure to ensure no joints

have been damaged in transit and site placement.

10.4 FILTRATION

It is important that a pre-filter and a post-filter be provided in your dryer

installation. These filters are included with each dryer. They are mounted

on model HB1500 and smaller.

A

NOTICE

All dryers must have proper filtration. Liquid water and oil must be

removed before the air enters the dryer. Ensure separators, pre-filters

and drains are in good working order. Failure to do so will void

warranty.

It is recommended that a mechanical separator be installed immediately

preceding the pre-filter to remove the bulk liquid and entrained water.

Coalescing pre-filters, located before the dryer, protect desiccant beds

from contamination by oil, entrained water, pipe scale, etc., thereby,

extending dryer desiccant life. Locate pre-filters as close to dryer as

possible.

FAILURE TO PROVIDE AND MAINTAIN A

HIGH

EFFICIENCY COALESCING PRE-FILTER WILL VOID DRYER

WARRANTY.

Post-filters, located after the dryer, help eliminate the possibility of

desiccant dusting carrying over into the air system.

A

WARNING

High temperature filters must be used to prevent rupture possibility in the

event dryer failure should occur. Consult your Ingersoll Rand

representative for appropriate filter selection.

10.5 DEW POINT TRANSMITTER INSTALLATION (OPTIONAL)

On dryers equipped with EMS, the dew point transmitter is shipped in a

separate container within the electrical enclosure to protect the

transmitter during shipment. Prior to using the EMS feature, the

transmitter must be installed in the sensor block located on the side of

or behind the electrical enclosure and the transmitter cable fastened to

the sensor. Note that the transmitter should only be installed when the

dryer is ready to be commissioned.

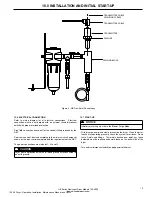

To install the Dew Point Transmitter:

• Remove Transmitter from original packaging.

• Verify that Washer is placed below Transmitter hex.

• Thread the Transmitter into the Sensor Block as shown.

• Attach the Transmitter Cable to the Transmitter. Be sure to fully

engage the Transmitter Cable Securing Screw into the mating thread in

the Transmitter.

14

HB Series Desiccant Dryer Models 150-8000

ingersollrandproducts.com

120.26 Dryer - Operation, Installation, Maintenance Manual, and Parts