Ensure the pulley and sheave are properly aligned and the motor

anchor screws are adequately retightened prior to restarting the

compressor.

•

CAUTION

Improper pulley/sheave alignment and belt tension

can result in motor overload, excessive vibration,

and premature belt and/or bearing failure.

To prevent these problems from occurring, ensure the pulley and

sheave are aligned and belt tension is satisfactory after installing

new belts or tensioning existing belts.

ELECTRIC DRAIN MAINTENANCE _____________________

NOTE

The following maintenance schedule has been

developed for typical applications. Maintenance

intervals should beshortened in harsher

environments.

DRAIN VALVE MAINTENANCE SCHEDULE

DAILY

Test the valve for proper

operation. Clean the filter screen

if needed.

MONTHLY (EVERY 30 DAYS)

Clean the filter screen.

To clean the filter screen, perform the following steps:

1.

Close the strainer ball valve completely to isolate it from the air

receiver tank.

2.

Press the TEST button on the timer to vent the pressure remaining

in the valve. Repeat until all pressure is removed.

•

CAUTION

High pressure air can cause injury from flying

debris. Ensure the strainer ball valve is completely

closed and pressure is released from the valve prior

to cleaning.

3.

Remove the plug from the strainer with a suitable wrench. If you

hear air escaping from the cleaning port, STOP IMMEDIATELY and

repeat steps 1 and 2.

4.

Remove the stainless steel filter screen and clean it. Remove any

debris that may be in the strainer body before replacing the filter

screen.

5.

Replace plug and tighten with wrench.

6.

When putting the EDV-2000 back into service, press the TEST

button to confirm proper function.

TANK INSPECTION __________________________________

The life of an air receiver tank is dependent upon several factors

including, but not limited to, operating conditions, ambient

environments, and the level of maintenance. The exact effect of

these factors on tank life is difficult to predict; therefore,

Ingersoll-Rand recommends that you schedule a certified tank

inspection within the first five years of compressor service. To

arrange a tank inspection, contact Ingersoll-Rand.

If the tank has not been inspected within the first 10 years of

compressor service, the receiver must be taken out of service until

it has passed inspection. Tanks that fail to meet requirements must

be replaced.

•

WARNING

Failure to replace a rusted air receiver tank could

result in air receiver tank rupture or explosion,

which could cause substantial property damage,

severe personal injury, or death. Never modify or

repair tank. Obtain replacement from service center.

10

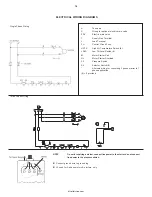

Position of weight and thrust pin when unit is operating.

http://air.irco.com