EN-7

16575250_ed1

EN

9. Install the Thrust Bearing Retainer (104) in the groove on

the Pinion to lock the components in position. Make

certain the Retainer is completely seated in the groove.

10. The Socket Retainer (115) for the Square Drive Spindle

(114) consists of a plunger, spring and washer. The hole

through the square on the working end of the Spindle has

an internal shoulder and the hole is deeper on one side of

the square than it is on the opposite side. Place the

spring into the deeper hole and insert the plunger into the

spring until the plunger is flush with the face of the

square. Holding the plunger side of the square against a

steel block, place the washer, chamfered side away from

the plunger, onto the plunger. With a rivet tool, rivet the

washer to the plunger.

11. Work some grease into the Lower Spindle Bearing (112)

and on the Bevel Gear.

12. Using a sleeve that will contact only the inner ring of the

Bearing, press the Lower Spindle Bearing, sealed side

first, onto the Spindle.

13. Slide the Bevel Gear of the Matched Gear Set (103) onto

the Spindle.

14. Apply a thread locking compound to the threads on the

Bevel Gear Retainer Nut (111) and Spindle. Allow the

compound to cure for the proper length of time and then

thread the Bevel Gear Retainer Nut onto the Spindle and

tighten it to 10.3 ft-lb (14 Nm) torque.

15. Install the assembled Spindle in the Angle Housing,

making certain the teeth of the Matched Gear Set mesh

and the Spindle turns freely.

16. Clean the threads of the Angle Housing and the Angle

Housing Cap (113). Apply a uniform coat of Vibra-Tite®**

VC3 No. 205 to the threads of the Angle Housing Cap

and allow the compound to cure between ten and twenty

minutes. Install the Angle Housing Cap and tighten the

Cap to a minimum of 15 to 18 ft-lb (20 to 24 Nm) torque.

17. Slide the Coupling Nut Retainer (109) and Coupling Nut

(108), threaded end trailing, over the notched end of the

Angle Housing.

18. Compress the Retainer and work it into the internal

groove in the nonthreaded end of the Nut.

For 3RL1A5

1. Work a light coat of

Ingersoll Rand

No. 67 Grease into

the gear teeth of the Bevel Pinion (103) and insert it, gear

end first, into the long bore of the Angle Housing (100).

2. Work 0.5 to 1 cc of grease into the Bevel Pinion Bearing

(110) and insert it, unstamped end first, into the bore of

the Angle Housing, after the Bevel Pinion.

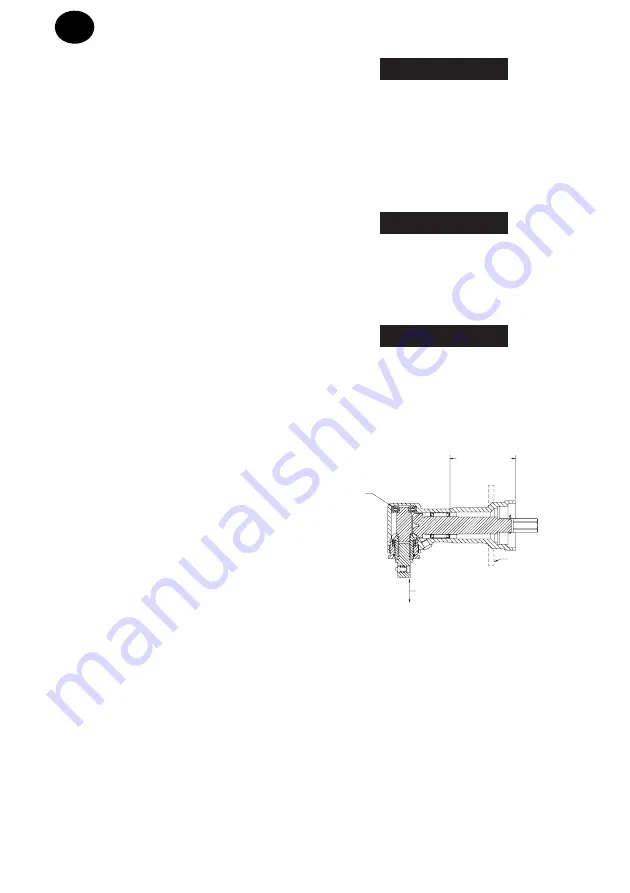

3. Support the Angle Housing on an angled support as

shown in Dwg. TPD790. Use a bearing inserting tool and

press the Bevel Pinion Bearing so the face is a maximum

of 1.32” (33.50 mm) but not less than 1.30” (33.00 mm)

below the end face of the Angle Head. Refer to Dwg.

TPD790.

4. Lubricate the Bevel Pinion Thrust Bearing (106) with 0.5

to 1 cc of grease. Install the Bearing on the rear of the

bevel pinion shaft with red-stained end of Bearing toward

the rear of the Angle Head. Secure Bearing on shaft with

Thrust Bearing Retainer (104).

5. The Socket Retainer (103A) consists of a Plunger, Spring

and Washer. The hole through the square on the working

end of the Spindle has an internal shoulder and the hole

is deeper on one side of the square than it is on the

opposite side. Place the Spring into the deeper hole and

insert the Plunger into the Spring until the Plunger is flush

with the face of the square. Holding the Plunger side of

the square against a steel block, place the Washer,

chamfered side away from the Plunger, onto the Plunger.

With a rivet tool, rivet the Washer to the Plunger

NOTICE

Do not get any thread locking compound in the bearing;

damage to the Bearing could result. Do not get any

grease on the inside diameter of the Bearing; grease will

prevent the compound from working.

6. Apply a small drop of a thread locking compound to the

small outside diameter of the upper spindle bearing shaft

on the Spindle (103).

7. Apply 2 to 4 cc of grease to the Upper Spindle Bearing

(102) and a light coat of grease to the gear teeth on the

Spindle. Press the Upper Spindle Bearing onto the

Spindle and allow the compound to dry completely.

NOTICE

Make sure that the Bevel Pinion is pulled outward toward

the Bevel Pinion Bearing before inserting the Spindle

into the Angle Head.

8. Insert the Spindle into the Angle Head until the Upper

Spindle Bearing seats into the recess of the Angle Head.

9. Install the Spindle Bearing (119) in the Cap.

10. Install the Angle Housing Cap finger-tight.

NOTICE

Spindle must turn freely.

11. With the Bevel Gear on the Spindle out of mesh with the

Bevel Pinion, measure the axial play of the Spindle (use

0.25 lb loads). Subtract 0.002” (0.051 mm) from the

reading for required shim thickness. Refer to Dwg.

TPB853.

3RL1A5 Angle Attachment

(Dwg. TPB853)

12. Unscrew and remove the Angle Housing Cap. While

pulling the Bevel Pinion outward toward the Bevel Pinion

Bearing, remove the Spindle from the Angle Head.

13. Insert the required number of shims as determined from

Step 11 in the upper bearing recess of the Angle Head.

14. Reassemble and test the Angle Head as indicated in

Steps 8, 10 and 11.

15. Once proper shimming has been achieved, remove the

Angle Housing Cap, clean the threads on the Angle Head

and the Angle Housing Cap, and apply a film of

Vibra-Tite® VC3 to the threads.

16. Install the Angle Housing Cap and tighten to 35 in-lb (3.9

Nm) torque.

17. Install the Rear Thrust Bearing Seat (105) on the Bevel

Pinion shaft with the flat face against the Thrust Bearing.

1.32”

(33.50 MM)

1.30”

(33.00 MM)

A

N

GLE

HO

US

IN

G

SUPP

O

R

T

A

XI

AL

-

PLA

Y

S

HIM TO .001” MIN.-

.003” M

A

X.

S

HIM

S