3

Form P7681 Edition 2

USING THE POWER MANAGEMENT SYSTEM

Impact Wrenches are not torque wrenches.

Connections requiring specific torque must be

checked with a torque meter after fitting with an

impact wrench.

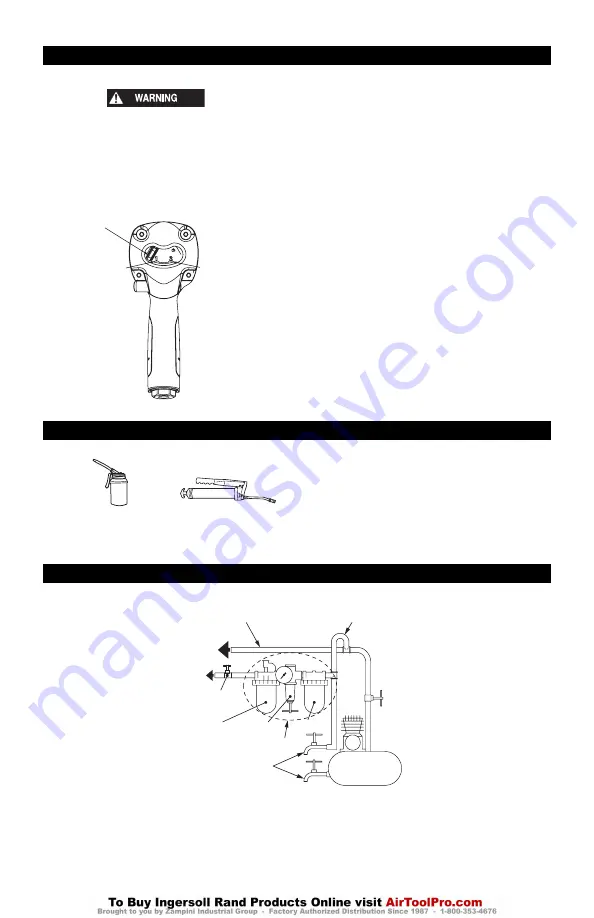

POWER MANAGEMENT SYSTEM

The 2130XP Impact Wrench incorporates a Power

Management System that allows the operator to

select three power output settings. These settings are

minimum power output, medium or maximum power

output in the clockwise direction only. The Air

Wrench will always operate at maximum power

output in the counterclockwise direction, no matter

what power output level is selected. The three power

setting indicators on the rear of the housing are for

reference only and DO NOT denote a specific power

output. The number 1 indicator designates minimum

power output and the number 2 setting indicator

denotes maximum power output. Placing the power

regulator in the center position denotes medium

power.

Power output can be further reduced in the clockwise

or ounterclockwise direction by using the variable

throttle. Air supply systems which do not deliver

adequate air pressure can affect power output at all

settings.

LUBRICATION

Ingersoll-Rand No. 50 Ingersoll-Rand No. 105

Always use an air line lubricator with these tools. We

recommend the following Filter-Regulator-

Lubricator (FRL) Unit:

Inside USA use FRL unit #C28-04-FKG0-28

Outside USA use FRL unit #C28-C4-FKG0

After each forty-eight hours of operation,

or as

experience indicates, inject about 4 cc of the recom

mended grease into the Grease Fitting (4).

INSTALLATION

POWER

REGULATOR

MINIMUM

MAXIMUM

(Dwg. TP2186)

F

L

R

Main Line(s) Inner Ø

to be 3X Size of

Air Tool's Inlet Ø

To Air

System

To Air

Tool

Lubricator

Emergency

Shut-Off

Valve

Regulator

Filter

Compressor

FRL

Drain Regularly

Branch Line(s) Inner Ø

to be 2X Size of

Air Tool's Inlet Ø

(Dwg. TPD905-2)