04576005_ed12

EN-1

EN

Product Safety Information

Intended Use:

These Air Orbital Sanders are designed for smoothing and sanding paint, fiberglass, wood and body

filler.

For additional information refer to Safety Information Manual Form 04580387.

Manuals can be downloaded from www.irtools.com.

Product Specifications

Installation and Lubrication

Size air supply line to ensure tool's maximum operating pressure (PMAX) at tool inlet. Drain condensate from

valve(s) at low point(s) of piping, air filter and compressor tank daily. Install a properly sized Safety Air Fuse

upstream of hose and use an anti-whip device across any hose coupling without internal shut-off, to prevent

hose whipping if a hose fails or coupling disconnects. See drawing 16577215 and table on page 2.

Maintenance frequency is shown in circular arrow and defined as h=hours, d=days, and m=months. Items

identified as:

Parts and Maintenance

When the life of the tool has expired, it is recommended that the tool be disassembled, degreased and parts

be separated by material so that they can be recycled.

The original language of this manual is English.

Tool repair and maintenance should only be carried out by an authorized Service Center.

Refer all communications to the nearest

Ingersoll-Rand

Office or Distributor.

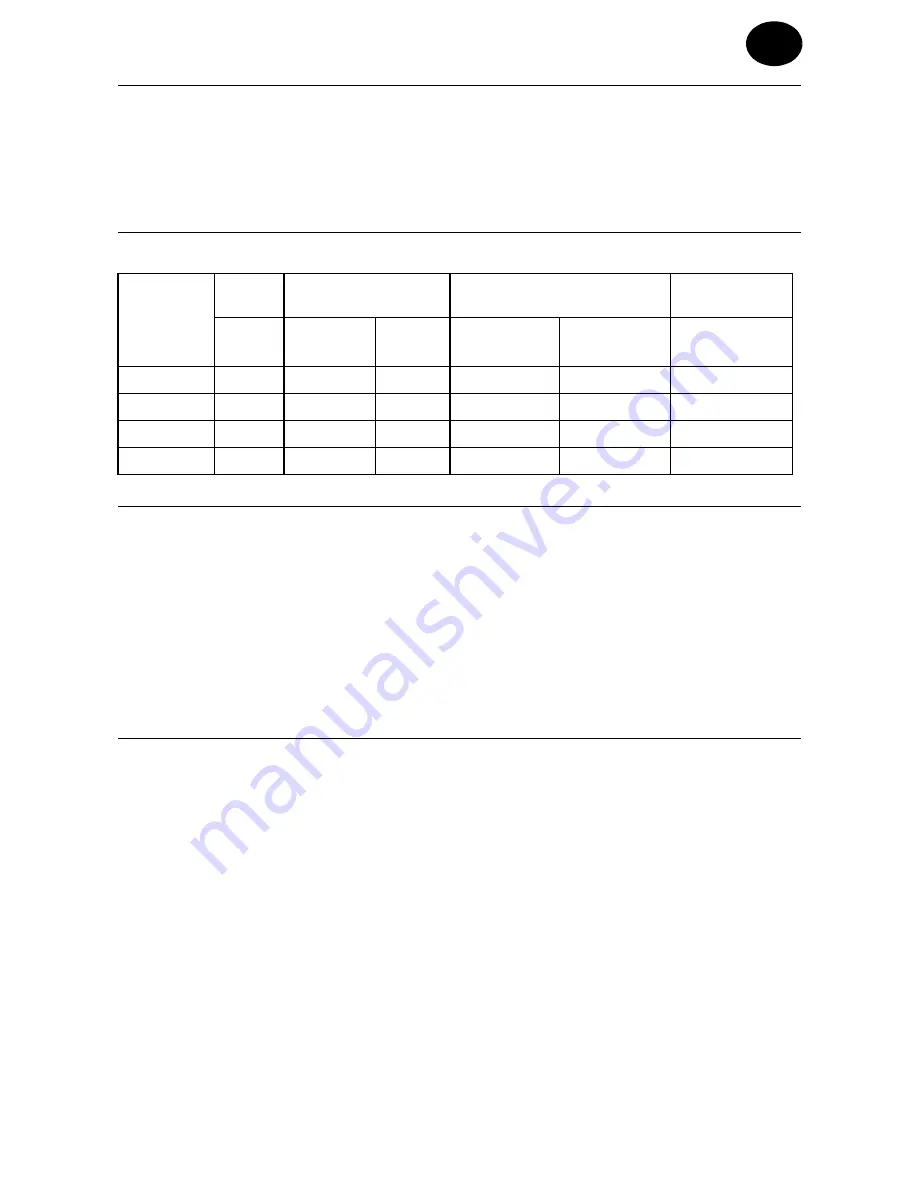

Model

Free

Speed

Pad Diameter

Sound Level dB (A)

(ISO15744)

Vibration Level

(ISO8662)

rpm

inch

mm

Pressure (L

p

)

“K

pA

”=3dB(A)

Power (L

w

)

“K

wA

”=3dB(A)

m/s²

4151

12,000

6

152

81.6

---

4.7

4151-2

12,000

6

152

81.6

---

4.7

4151-5

12,000

5

127

81.6

---

4.7

4152

12,000

6

152

81.6

---

4.8

1.

Regulator

5.

Coupling

2.

Emergency shut-off valve

6.

Safety Air Fuse

3.

Hose diameter

7.

Grease - Remove sanding pad and inject

4.

Thread size

Summary of Contents for 300G Series

Page 2: ...2 04576005_ed12 Dwg 16577215 inch mm NPT I R cm3 5 16 8 1 4 68 4 2 5 3 1 4 6 7 1m 3 4 7 ...

Page 29: ...Notes ...

Page 30: ...Notes ...

Page 31: ...Notes ...