Page 2 of 8

6544X-X (en)

DISASSEMBLY OF AIR MOTOR

NOTE: All threads are right hand.

Place motor in up stroke position. This can be accom-

plished by pushing (48) rod toward the top of the air

motor.

Remove four (1) screws from (2) defl ector.

Remove (2) defl ector.

Remove six (3) screws from (8) air motor cap.

Remove (8) air motor cap and (10) gasket.

Loosen four (4) screws (which hold (12) valve plate and

(9) valve guide) until (9) valve guide can be removed by

pulling upward (see fi gure 9, page 6).

1.

2.

3.

4.

5.

6.

PARTS LIST / 6544X-X & 6546X-X

Item Description

(size)

(Qty) Part No.

1 Screw

(#8 - 32 x 7/8”) (not shown)

(4) Y136-90-S

2 Defl ector

(not shown)

(1) 90409

3 Screw

(#10 - 24 x 1/2”)

(6) 95956827

4 Screw

(#8 - 32 x 3/4”)

(4) Y19-89-S

5 Washer

(4) 90084

6 Screw

(1/4” - 28 x 3/4”)

(2) Y119-49-C

7 Washer

(1/4” i.d.)

(2) Y14-416

8 Air Motor Cap

(1) 90078

9 Valve Guide

(1) 90093

10 Gasket

(1) 90083-1

11 Insert

(1) 90097

12 Valve Plate and Pin Assembly

(1) 65028

12a Roll Pin

(3/32” o.d. x 3/4” long)

(2) Y178-26-S

13 Insert Spring Assembly

(1) 65032

14 Valve Insert

(1) 90796

15 Gasket

(1) 90091

16 “O” Ring

(1/16” x 1-3/8” o.d.)

(2) Y325-26

17 Washer

(1) 91344

18 “O” Ring

(1/16” x 3/4” o.d.)

(2) Y325-16

19 Head Assembly

(1) 65889

20 “U” Cup

(3/16” x 1-3/8” o.d.)

(1) Y186-51

21 “O” Ring

(1/8” x 4-1/4” o.d.)

(2) Y325-242

22 Screw

(#8 - 32 x 3/8”)

(4) Y136-85-S

24 Piston Assembly

(1) 61851

27 Rod Assembly

(see chart, page 4)

(1) - - - - -

Item Description

(size)

(Qty) Part No.

28 Cylinder

(see chart, page 4)

(1) - - - - -

29 Tube

(see chart, page 4)

(1) - - - - -

30 Base and Bearing Ass’y

(see chart, page 4)

(1) - - - - -

31 Valve Piston

(1) 92394

32 Washer

(1) 90105

33 Gland

(1) 91006

34 Seal

(1) 91007

35 “O” Ring

(0.103” x 1.255” o.d.)

(1) 91207

36 Extension Rod

(1) 90080

38 Adapter

(1) 92393

39 Gland

(1) 90114

40 Washer

(1) 91345

41 “O” Ring

(1/16” x 7/16” o.d.)

(1) Y325-11

42 Bolt

(see chart, page 4)

(4) - - - - -

43 Snap Ring

(see chart, page 4)

(1) - - - - -

44 Washer

(see chart, page 4)

(1) - - - - -

45 “U” Cup

(see chart, page 4)

(1) - - - - -

46 Washer

(see chart, page 4)

(1) - - - - -

47 Nut

(see chart, page 4)

(4) - - - - -

48 Piston Rod

(see chart, page 4)

(1) - - - - -

49 “O” Ring

(see chart, page 4)

(1) - - - - -

50 Ground Lug

(1) 93006

51 Ground Label

(not shown)

(1) 93007

Items included in Service Kit

61268

(continued on page 5)

“Smart Parts”, keep these items on hand in addition to the service kits

for fast repair and reduction of downtime.

Includes item (12a) roll pin (qty 2).

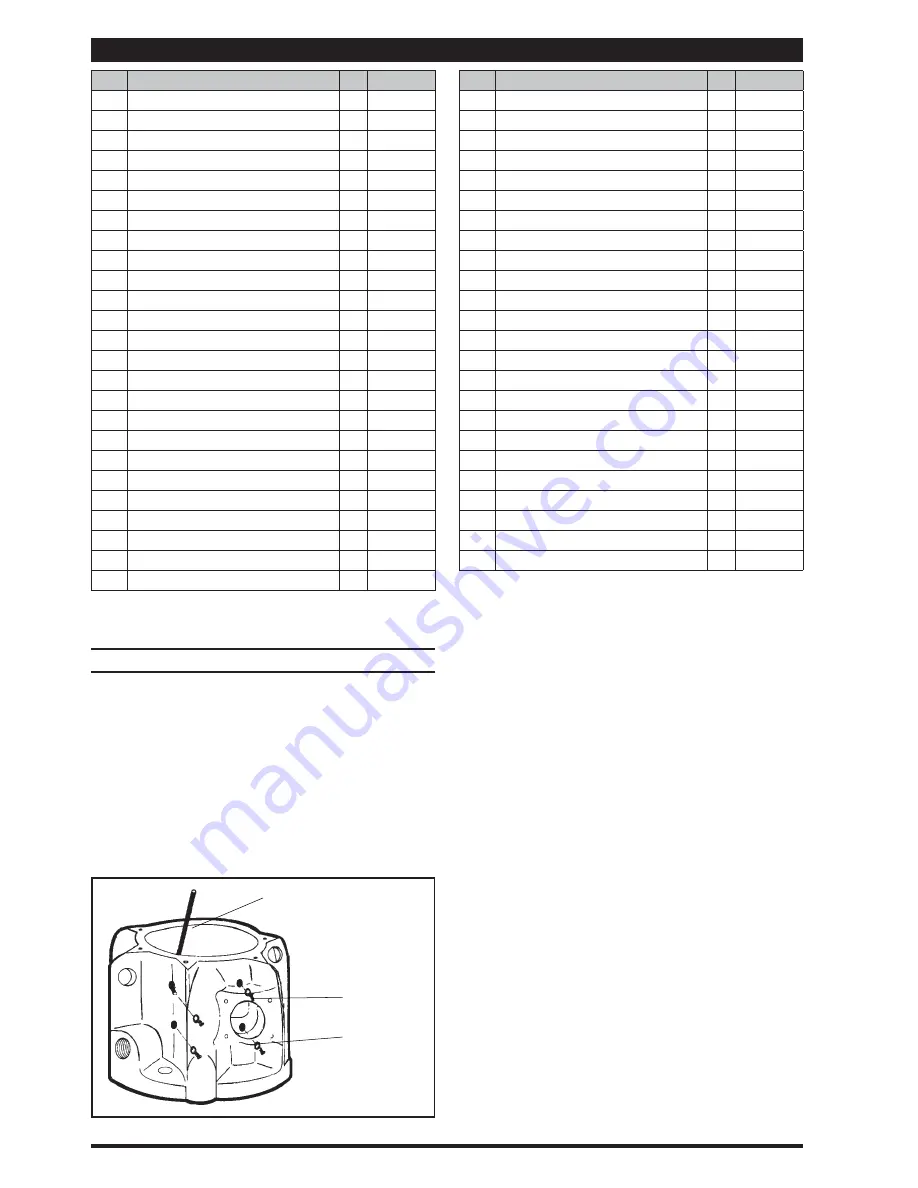

Figure 2

(Use an Allen wrench to

push out screws and

washers as shown.)

4

Screws (4)

5

Washers (4)

Allen Wrench

Remove four (4) screws and four (5) washers from (19)

head assembly by pressing outward with a small allen

wrench, as illustrated in fi gure 2.

With the aid of a screwdriver, unhook the legs of (13) in-

sert spring assembly from the bottom of (12) valve plate.

Remove (12) valve plate and (13) insert spring assembly

from (19) head by pulling upward. If (12) valve plate is

stuck, tap the top edge lightly with a soft face mallet.

Do

not tap with anything metallic

.

Remove both (11 and 14) inserts and (13) insert spring

assembly from (12) valve plate.

Remove (15) gasket from (19) head assembly.

Remove two (6) screws and two (7) lock washers from

(33) gland in (19) head assembly.

With fingers, pull (31) valve piston upward until (33)

gland has pulled out of its chamber.

Remove (33) gland by sliding it up over (31) valve piston.

Remove (34) seal and (35) “O” ring from (33) gland (see

fi gure 8, page 6).

Disassemble (31) valve piston from (38) adapter as

shown in fi gure 4, page 3.

Pull (38) adapter upward until assembly is taut and

grasp (36) extension rod with fi ngers, as shown in fi gure

9, page 6. Grasp (36) extension rod below (38) adapter.

Now push (38) adapter down on (36) extension rod and

remove (32) washer from (36) extension rod. Now re-

move (38) adapter.

Remove (17) washer and (20) “U” cup from (38) adapter.

Remove four (47) nuts from four (42) bolts.

Remove four (42) bolts.

Remove (19) head assembly and place on the work-

bench with (8) cap side down. This action will allow (40)

washer to fall out of its cavity.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.