3

ADJUSTMENTS

Accessory Installation

Always turn off the air supply and disconnect the air

supply hose before installing, removing or adjusting any

accessory on this tool or before performing any

maintenance on this tool.

1.

The Upper Sleeve should be replaced each time a bit is

replaced.

2.

Replace the Lower Sleeve at the first indication of wear.

Wear is indicated by a “rounding out” of the square

opening in the Lower Sleeve.

3.

Replace the Rubber Bumper when the Lower Sleeve

extends out of the Retainer Nut more than 1/8”.

For Threaded Retainer No. 9001–200

1.

It is extremely important that the Retainer Nut is properly

positioned on the tool. Under normal circumstances, the

Lock Spring is sufficient to keep the Retainer Nut in

place.

2.

When the tool is used in a continuous duty cycle, it is

often necessary to use a Lock Key and Lock Pin in

conjunction with the Lock Spring. This will prevent the

loosening of the Retainer Nut which could cause damage

to the bit and other front end components.

For Plain–Type Retainer No. 11001–18

1.

To remove the accessory, clamp the Barrel (20) in

leather–covered or copper–covered vise jaws with the

accessory end up.

2.

Remove the Lock Spring (31).

3.

Slide the Retainer (30) off the Barrel and remove the

Rubber Bumper (25) from the inside of the Retainer.

4.

Slide the Lower Sleeve (24) off the accessory and remove

the accessory from the Barrel.

5.

To install the accessory, reverse the above procedure.

PLACING TOOL IN SERVICE

LUBRICATION

Ingersoll–Rand No. 10

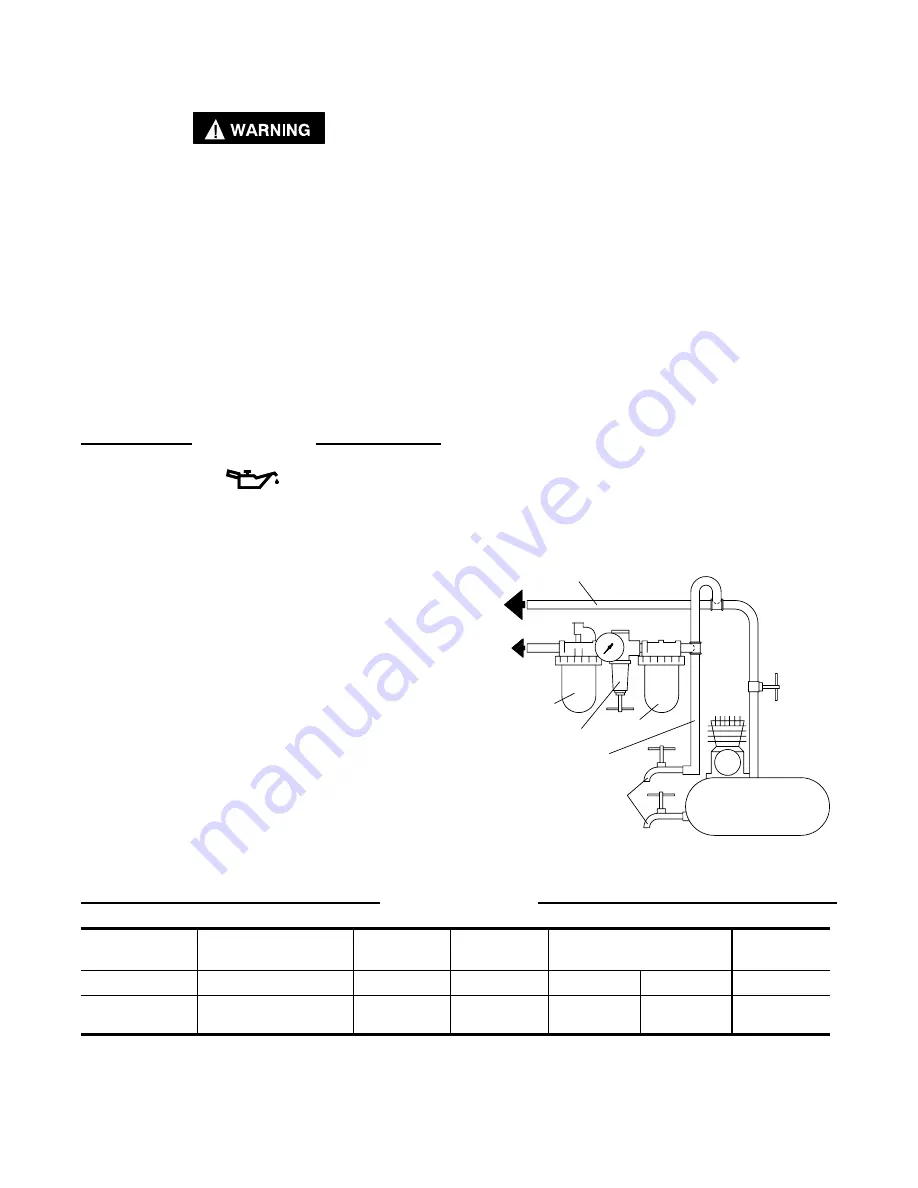

Always use an air line lubricator. We recommend the

following Filter–Lubricator–Regulator Unit:

For International – No. 3LUB8

Install the air line lubricator as close to the tool as possible.

Before attaching the air hose, place several drops of

Ingersoll–Rand No. 10 Oil into the air inlet. This should be

done each day even when an air line lubricator is used.

During the working day, check the tool to ensure that the

retainer components are lubricated.

After each two or three hours of operation, unless an air

line lubricator is used, place several drops of Ingersoll–Rand

No. 10 Oil into the air inlet.

Before storing Air Hammer or if the tool is to be idle for a

period exceeding 24 hours, pour about 3 cc or oil into the air

inlet and operate the tool for 5 seconds. This will coat the

internal parts with oil and prevent rusting while the tool is

idle.

Never use a heavy oil or an oil that forms gum. Either will

clog the small parts, restrict valve motion and cause loss of

efficiency.

If the operation of the Air Hammer becomes sluggish, pour

3 cc of a clean, suitable, cleaning solution into the air inlet and

operate the tool for 30 seconds. Lubricate in the regular

manner immediately after flushing.

MAIN LINES 3 TIMES

AIR TOOL INLET SIZE

TO

AIR

SYSTEM

TO

AIR

TOOL

LUBRICATOR

REGULATOR

FILTER

BRANCH LINE 2 TIMES

AIR TOOL INLET SIZE

DRAIN REGULARLY

COMPRESSOR

(Dwg. TPD905–1)

SPECIFICATIONS

Model

Handle

Impacts

per min.

Piston

Stroke

H

Sound Level

dB (A)

♦

Vibrations

Level

in (mm)

Pressure

Power

m/s

2

9001–EU

Grip, with Outside

Throttle

850

9 (229)

115.2

128.2

7.6

H

Tested in accordance with PNEUROP PN8NTC1.2 under load

♦

Tested in accordance with ISO8662–5