26

( )

Book 22464945 (1/07)

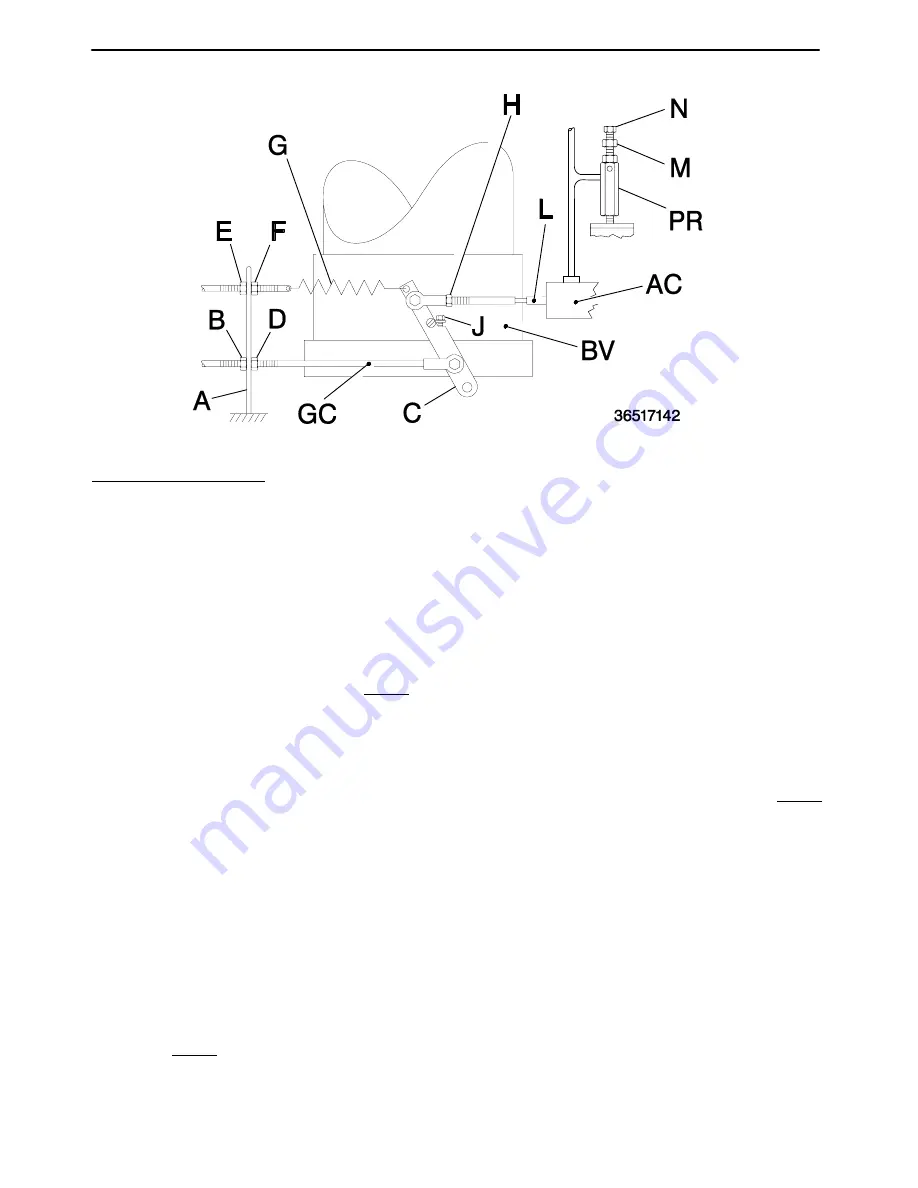

SPEED AND PRESSURE REGULATION

Adjustment Instructions

The operating pressure of this unit was set at the facto-

ry to the maximum rating (at full speed). See General

Data. However, this pressure may be reset down to

150 psi (1050 kPa).

Normally, regulation requires no adjusting; but if prop-

er adjustment is lost, proceed as follows:

1.

WITH UNIT STOPPED

, disconnect rod end

bearing on governor cable (GC) at engine gov-

ernor lever.

2.

At bracket (A) near butterfly valve (BV) run nut

(B) back on governor cable housing. Push gov-

ernor cable housing toward lever (C). Tighten

nut (D).

3.

Loosen nut (E) to relax spring (G).

4.

Loosen nut (H). Turn rod (L) in Air Cylinder (AC)

until approximately 3/4 inch (20 mm) between

nut (H) and flats on rod (L).

5.

Turn rod (L) One round into rod end bearing.

Tighten nut (H). Rotate butterfly shaft/lever (C),

open and close, several times to assure that

linkage is not binding.

6.

With engine governor lever in full speed posi-

tion, reconnect rod end bearing.

7.

Take slack out of spring (G) by moving nuts (E)

and (F). Tighten nuts.

XHP 900 Units ONLY:

Adjust spring so it is full

stretched, and nut (F) is at far end of rod, closest to

spring (G). Tighten nuts.

8.

Start unit and allow to warm up for 3 to 5 min-

utes.

9.

Push “Service Air” button on control panel.

10.

With service air valve closed, adjust pressure

regulator (PR) to rated pressure (*) plus 10 psi

(70 kPa) as follows:

11.

Loosen locknut (M) counterclockwise;. Turn

adjustment cap (N) clockwise to increase pres-

sure, counterclockwise to decrease pressure.

12.

Set no load speed (*) by adjusting position of

rod end bearing on governor cable at engine.

Tighten lock nut.

13.

Open service air valve and observe full load en-

gine speed (*). Adjust regulator to give rated

operating pressure (*). Tighten locknut (M).

14.

Close and slowly open service air valve. If en-

gine speed surges, increase tension on spring

(G) by moving nuts (E) and (F).

XHP900 Units

ONLY:

Should not be adjusted by moving nuts

(E) and (F). See Step 7.

If set speeds are not

correct, repeat steps 12, 13 and 14 as required.

15.

To regulate to any pressure between 150 psi

(1050 kPa) and maximum rating (*), make ad-

justments at the pressure regulator.