4

PLACING TOOL IN SERVICE

4.

Experience will indicate the correct amount of pressure to

the tool. Normally, the amount of pressure is correct when

the tool hits rhythmically, is comfortable to hold and

works efficiently.

Do not repair the tool at the work site. Always take

the tool to a repair shop. Never drag the tool on the

ground. The air port and other openings will become

clogged with dirt and debris.

Compressed air is dangerous. When blowing the line

clear of dirt, wear eye protection and keep the air line

directed toward a safe, clear area.

5.

Always blow out the air line before using to clear the line

of dirt.

Do not operate the tool unless the chisel is against

the work since this will cause premature wear of

parts and reduce the vibration isolation properties

of the tool.

6.

Always break material to the point of “give.” Cracking

does not result in a complete break. Clear away rubble

as it is broken since uncleared rubble blocks the point

of “give.”

7.

Always take the right size “bite” with the tool. When

working new material, experiment to find the right size

“bite” required for breaking that material efficiently.

If “bites” are too big, the operator will try to pry

with the tool. This could break the chisel. The tool

is designed for demolition, not prying. Always use a

pick for prying.

If “bites” are to small, the operator will be working

too slowly.

8.

If the chisel or accessory should become stuck, do not

use excessive force or mechanical means on the tool to

pull out the chisel. Doing so will damage the vibration

isolation unit. Break out the stuck chisel with a spare

chisel or tool.

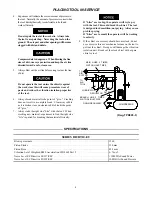

MAIN LINES 3 TIMES

AIR TOOL INLET SIZE

TO

AIR

SYSTEM

TO

AIR

TOOL

LUBRICATOR

REGULATOR

FILTER

BRANCH LINE 2 TIMES

AIR TOOL INLET SIZE

DRAIN REGULARLY

COMPRESSOR

(Dwg. TPD905–1)

SPECIFICATIONS

SERIES DB/DT10–EU

Blows per minute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1560

Piston Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150 mm

Piston Bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.5 mm

Vibration Level Weighted RMS Acceleration ISO 8662 Part 5 . . . . . . . . . . . . . . . . . . . . . . . . 6–7m/s2

Noise Level EC Directive 84/537/EEC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <108LWA Sound Power

Noise Level EC Directive 89/392/EEC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100DB (A) Sound Pressure