20

MHD56114 - Edition 4

Periodic Inspection

Periodic inspection intervals for winch use under various

conditions is listed below:

Disassembly may be required as a result of frequent inspection

findings or in order to properly inspect the individual components.

Disassembly steps are described in the “MAINTENANCE”

section. Maintain written records of periodic inspections to

provide an accumulative basis for continuing evaluation. Inspect

all items listed in ‘Frequent Inspection.’ Also inspect the

following:

1.

SIDE RAILS and UPRIGHTS. Check for deformed, cracked

or corroded main components. Replace damaged parts.

2.

FASTENERS. Check retainer rings, split pins, capscrews,

nuts and other fasteners on winch, including mounting bolts.

Replace if missing or damaged and tighten if loose.

3.

DRUM and SHEAVES. Check for cracks, wear or damage.

Replace if necessary.

4.

WIRE ROPE. In addition to “Frequent Inspection”

requirements, also inspect for the following:

a.

Build-up of dirt and corrosion. Clean with steam or a

stiff wire brush to remove dirt and corrosion if

necessary.

b.

Loose or damaged end connection. Replace if

loose or damaged.

c.

Check wire rope anchor is secure in drum.

d.

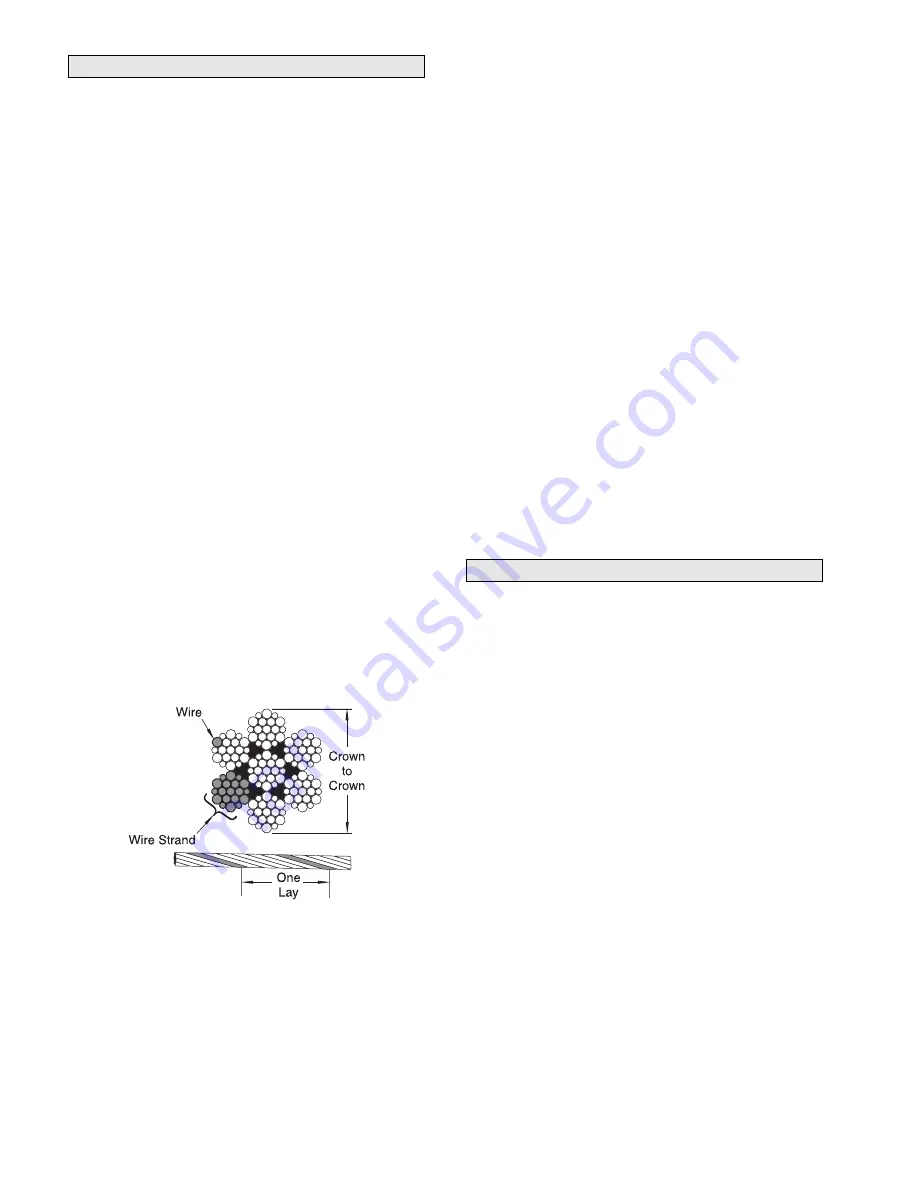

Verify wire rope diameter. Measure the diameter of the

wire rope from crown-to-crown throughout the life of

the wire rope. Recording of the actual diameter should

only be done with the wire rope under equivalent

loading and in the same operating section as

accomplished during previous inspections. If the actual

diameter of the wire rope has decreased more than 1/64

inch (0.4 mm) a thorough examination of the wire rope

should be conducted by an experienced inspector to

determine the suitability of the wire rope to remain in

service. Refer to Dwg. MHP0056 on page 20.

(Dwg. MHP0056)

5.

ALL COMPONENTS. Inspect for wear, damage, distortion,

deformation and cleanliness. If external evidence indicates

damage, disassemble as required to conduct a detailed

inspection. Inspect gears, shafts, bearings, sheaves, springs

and covers. Replace worn or damaged parts. Clean, lubricate

and reassemble.

6.

BRAKES. Individually test brakes installed to ensure proper

operation. Brakes must hold a 125% rated load at mid drum

without slipping. If indicated by poor operation or visual

damage, disassemble and repair brake(s). Check all brake

surfaces for wear, deformation or foreign deposits. Clean

and replace components as necessary. Adjustments can be

made to the drum band brake to compensate for normal

brake lining wear. Refer to ‘Adjustments’ in the

“MAINTENANCE” section. If brake band cannot be

adjusted to hold rated load, replace the brake band assembly.

Adjustments cannot be made to the disc brake. The disc

brake must be repaired as described in the

“MAINTENANCE” section.

7.

FOUNDATION or SUPPORTING STRUCTURE. Check

for distortion, wear and continued ability to support winch

and rated load. Ensure winch is firmly mounted and that

fasteners are in good condition and tight.

8.

LABELS AND TAGS. Check for presence and legibility of

labels. Replace if damaged or missing.

9.

DRUM GUARD (optional feature). Verify fasteners are tight

and in good condition. Ensure guard is in good condition.

10. EMERGENCY STOP VALVE (optional feature). During

winch operation verify the emergency stop valve operation.

Valve must stop winch operation quickly. Valve must reset

properly. Refer to ‘Emergency Stop Valve’ in the

“OPERATION” section for procedures.

11. OVERLOAD DEVICE (optional feature). Ensure overload

device is properly set to stop the winch when loads exceed

150% (+/- 25%) of winch rated capacity. If winch does not

shut down, contact your distributor or the factory for repair

information.

Winches Not in Regular Use

1.

Equipment which has been idle for a period of one month or

more, but less than six months, shall be given an inspection

conforming to the requirements of “Frequent Inspection”

before being placed in service.

2.

Equipment which has been idle for a period of over six

months shall be given a complete inspection conforming

with the requirements of “Periodic Inspection” before being

place in service.

3.

Standby equipment shall be inspected at least semiannually

in accordance with the requirements of “Frequent

Inspection”. In abnormal operating conditions equipment

should be inspected at shorter intervals.

NORMAL

HEAVY

SEVERE

yearly

semiannually

quarterly