MHD56114 - Edition 4

25

MAINTENANCE

WARNING

WARNING

• Never perform maintenance on the winch while it is

supporting a load.

• Before performing maintenance, tag controls:

WARNING - DO NOT OPERATE -

EQUIPMENT BEING REPAIRED.

• Only allow personnel trained in safety and service on this

winch to perform maintenance.

• After performing any maintenance on the winch, test winch

to 125% of its rated line pull at mid drum before returning to

service. (Testing to more than 125% of rated line pull may be

required to comply with standards and regulations set forth in

areas outside the USA.)

• Shut off air system and depressurize air lines before

performing any maintenance.

Reduction Gear Assembly

It is recommend that the first oil change be done after

approximately 50 hours initial operation. Always inspect removed

oil for evidence of internal damage (metal shavings, dirt, water,

etc.). Refer to the “LUBRICATION” section for recommended

lubricants.

Adjustments

Disc Brake

Brake adjustment is

not

required. If the disc brake does not hold

100% of rated load at mid drum, disassemble and repair.

NOTICE

NOTICE

• Winches are provided with a breather plug located at the top

of the disc brake housing. If the brake assembly is removed or

repaired ensure the breather is installed and located at the top

of the brake housing during reassembly.

Manual Drum Band Brake (optional feature)

Refer to Dwg. MHP1402 on page 47.

1.

Release wire rope tension on the drum.

2.

Raise handle (135) to free brake bands (136) and (137).

3.

Remove cotter pin (139) and pin (138).

4.

Rotate brake link stud (141) clockwise to increase brake

torque.

5.

Install pin (138) and check adjustment.

NOTICE

• If brake band cannot be adjusted to hold the rated load,

replace the brake band assembly.

6.

Adjust brake so when brake handle locks (goes over-center),

brake will hold rated load.

7.

Install cotter pin (139) when adjustment is complete.

8.

Lift up the brake handle to free position.

Automatic Drum Band Brake (optional feature)

Refer to Dwg. MHP2508 on page 46.

For adjustments, references to “clockwise” and

“counterclockwise” directions, in the text, refer to directions as

viewed from the head end of capscrew (120).

NOTICE

• If brake band cannot be adjusted to hold rated load, replace

the brake band assembly.

1.

Loosen jam nut (117) closest to plunger (114).

2.

Adjust band assembly using capscrew (120).

a.

To loosen band brake, turn capscrew (120) in the

counterclockwise direction.

b.

To tighten band brake, turn capscrew (120) in the

clockwise direction.

NOTICE

• If the capscrew (120) is not accessible, the jam nut (117)

[located closest to the head of capscrew (120)] may be used to

adjust the band brake. Ensure capscrew turns with nut.

3.

When adjustments are complete tighten jam nut (117) closest

to plunger (114).

Pilot Air Control Valve Adjustment (optional feature)

Refer to Dwg. MHP2513 on page 51.

If winch operating speeds differ from performance specifications

pilot air control valve may require adjustment.

1.

Loosen nut (773) and adjust adjusting screw (270), located in

valve cap end (268), until drum speed for no-load haul-in

equals drum speed for full load payout.

2.

Rotate screw (270) ‘out’ to increase drum speed and ‘in’ to

decrease drum speed. It is suggested that a chalk mark be

placed on drum flange so that drum rpm can be accurately

counted.

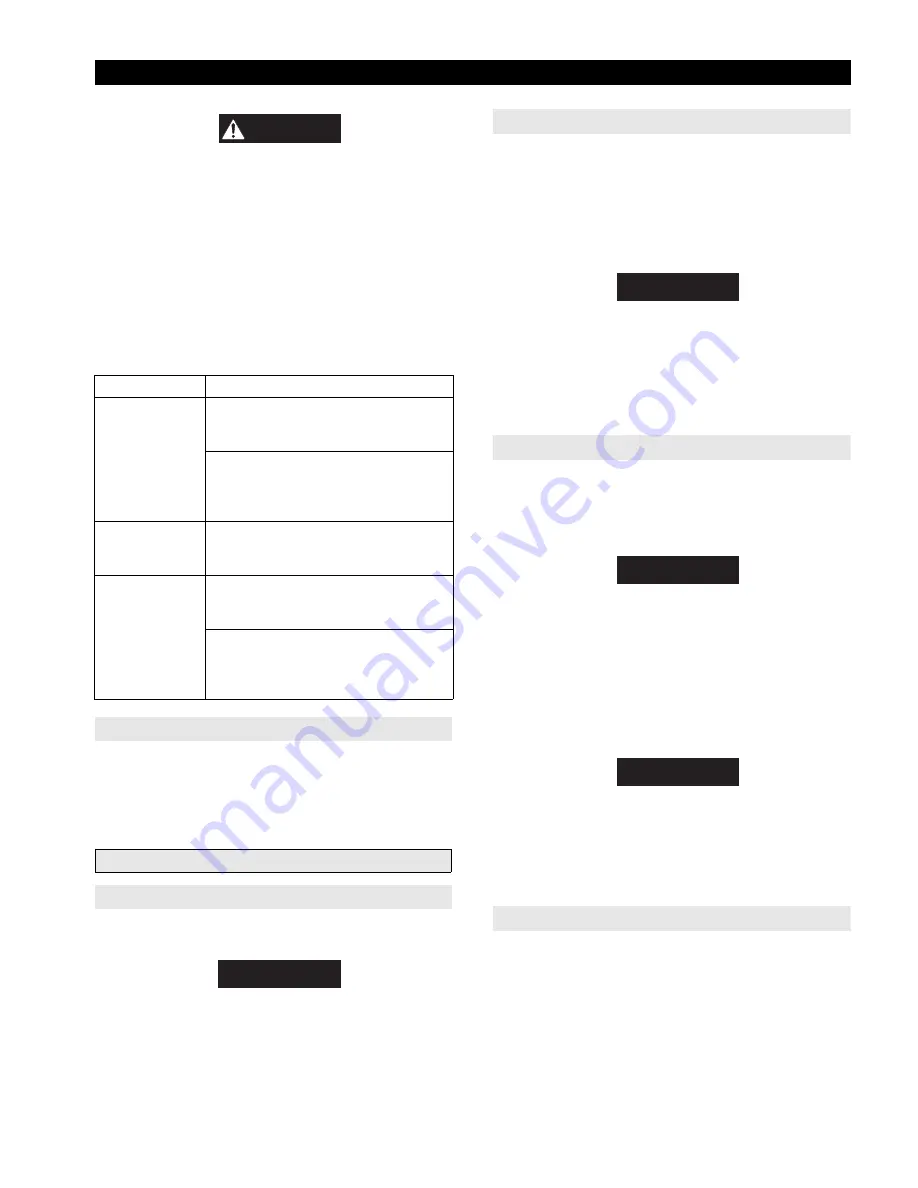

INTERVAL

MAINTENANCE CHECK

Start of each shift

(Operator or

Maintenance

Personnel)

Make a thorough visual inspection of the

winch for damage. Do not operate winch if

damaged.

Operate winch at low RPM in both

directions. Winch must operate smoothly

without sticking, binding or abnormal

noises. Check operation of the brake(s).

3 Months

(Maintenance

Personnel)

Inspect drum brake friction linings. Clean

or replace parts as required. Adjust drum

brake as necessary.

Yearly

(Maintenance

Personnel)

Inspect the winch gearing, shafts and

bearings for wear and damage. Repair or

replace as necessary.

Check all supporting members, including

foundations, fasteners, nuts, sheaves and

rigging, etc. for indications of damage or

wear. Repair or replace as required.