Only allow

Ingersoll Rand

trained technicians to perform maintenance on this product. For additional information contact

Ingersoll Rand

factory or nearest

Distributor.

For additional supporting documentation refer to Table 1 ‘Product Information Manuals’ on page 2.

Manuals can be downloaded from http://www.ingersollrandproducts.com.

The use of other than genuine Ingersoll Rand replacement parts may result in safety hazards, decreased performance and increased maintenance and will invalidate all

warranties.

Original instructions are in English. Other languages are a translation of the original instructions.

Refer all communications to the nearest Ingersoll Rand Office or Distributor.

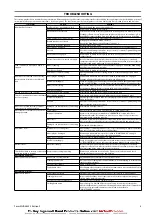

Table 1: Product Information Manuals

Publication

Part/Document Number Publication

Part/Document

Number

Product Safety Information Manual (Non-Man Rider)

MHD56250

Product Maintenance Information Manual (Non-Man Rider)

MHD56301

Product Safety Information Manual (Man Rider)

MHD56251

Product Maintenance Information Manual (Man Rider)

MHD56304

Product Parts Information Manual

MHD56302

INSPECTION

Frequent inspections should be performed on equipment in regular service. Refer

to Product Information Manual. Some options may not apply to your product, refer

to data (name) plate for correct model and any applicable manuals.

n

Periodic Inspection

Refer to Table 2 ‘Inspection Classifications’ on page 2 for suggested winch

inspection classifications for Periodic Inspection intervals. Select conditions most

appropriate to application.

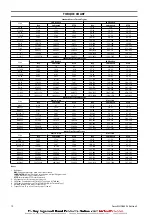

Table 2: Inspection Classifications

Conditions

Normal

Heavy

Severe

Typical Use (operating time)

Infrequent

Regular

Continual/Constant

Load Range

60% of Capacity 75% of Times Used

80% of Capacity 75% of Times Used

100% of Capacity 75% of Times Used

Installation

Protected/Enclosed/Dry

Not Sheltered/Exterior

Full Exposure

Atmosphere

Clean/Non-Corrosive

Dirty/Non-Corrosive/Freshwater Marine

Dirty/Corrosive/Saltwater Marine

Climate

Dry/Stable Temperature

Wet/Moderate Temperature Fluctuations

Wet/Severe Temperature Fluctuations

Maintain written records of periodic inspections to provide an accumulative basis

for continuing evaluation. Inspect all items listed in “Frequent Inspection.” Also

inspect the following at the suggested intervals recommended in Table 3

‘Maintenance Interval Chart’ on page 3:

1.

Siderails and Uprights. Check for deformed, cracked or corroded main

components. Replace damaged parts.

2.

Fasteners. Check retainer rings, capscrews, nuts and other fasteners on winch,

including mounting bolts. Replace if missing or damaged and tighten if loose.

3.

Drum and Sheaves. Check for cracks, wear or damage. Replace if necessary.

4.

Wire Rope. In addition to “Frequent Inspection” requirements, also inspect for

the following:

a. Build-up of dirt and corrosion. Clean with steam or a stiff wire brush to

remove dirt and corrosion if necessary.

b. Loose or damaged end connection. Replace if loose or damaged.

c. Check wire rope anchor is secure in drum.

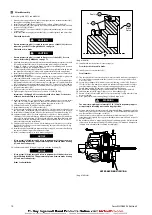

d. Verify wire rope diameter. Measure the diameter of the wire rope from

crown-to-crown throughout the life of the wire rope. Recording of the actual

diameter should only be done with the wire rope under equivalent loading

and in the same operating section as accomplished during previous

inspections. If the actual diameter of the wire rope has decreased more than

1/64 inch (0.4 mm) a thorough examination of the wire rope should be

conducted by an experienced inspector to determine the suitability of the

wire rope to remain in service. Refer to Dwg. MHP0056 on page 2.

A

B

C

D

(Dwg. MHP0056)

5.

All Components. Inspect for wear, damage, distortion, deformation and

cleanliness. If external evidence indicates damage, disassemble as required to

conduct a detailed inspection. Inspect gears, shafts, bearings, sheaves, springs

and covers. Replace worn or damaged parts. Clean, lubricate and reassemble.

6.

Brakes. Individually test brakes installed to ensure proper operation. Brakes

must hold a 125% rated load at mid drum without slipping. If indicated by poor

operation or visual damage, disassemble and repair brake(s). Check all brake

surfaces for wear, deformation or foreign deposits. Clean and replace

components as necessary. Adjustments can be made to the drum band brake

to compensate for normal brake lining wear. Refer to ‘Adjustments’ in the

“MAINTENANCE” section. If brake band cannot be adjusted to hold rated load,

replace the brake band assembly. Adjustments cannot be made to the disc brake.

The disc brake must be repaired as described in the “MAINTENANCE” section.

7.

Foundation or Supporting Structure. Check for distortion, wear and continued

ability to support winch and rated load. Ensure winch is firmly mounted and that

fasteners are in good condition and tight.

8.

Limit Switches (optional feature). Operate winch in both directions to activate

limit switches. Limit switches should engage (stop winch operation) at

established settings (+/- 2 feet [+/- 0.6 meters]). Reset limit switch by operating

winch in opposite direction. Refer to ‘Limit Switch Adjustment’ in

“MAINTENANCE” section.

9.

Winch Guard (optional feature). Verify fasteners are tight and in good

condition. Ensure guard is in good condition.

10.

Emergency Stop Valve (optional feature). During winch operation verify the

emergency stop valve operation. Valve must stop winch operation quickly. Valve

must reset properly. Refer to ‘Emergency Stop Valve’ in the “OPERATION” section

in Product Information Manual for procedures.

11.

Overload Device (optional feature). Ensure overload device is properly set to

stop the winch when loads exceed 150% (+/- 25%) of winch rated capacity. If

winch does not shut down, contact your distributor or the factory for repair

information.

12.

Press Roller (optional feature). Inspect rollers for wear and grooves. Ensure

rollers freely rotate. Replace rollers if worn or grooved. Replace bearings if

rotation is rough or stiff.

13.

Labels and Tags. Check for presence and legibility of labels. Replace if damaged

or missing.

n

Records and Reports

Inspection records, listing all points requiring periodic inspection should be

maintained for all load bearing equipment. Written reports, based on severity of

service, should be made on the condition of critical parts as a method of

documenting periodic inspections. These reports should be dated, signed by the

person who performed the inspection, and kept on file where they are readily

available for review.

n

Maintenance Intervals

Refer to “Periodic Inspection” and Table 2 ‘Inspection Classifications’ on page 2 for

maintenance interval guidance.

2

Form MHD56303 Edition 2