30

2.

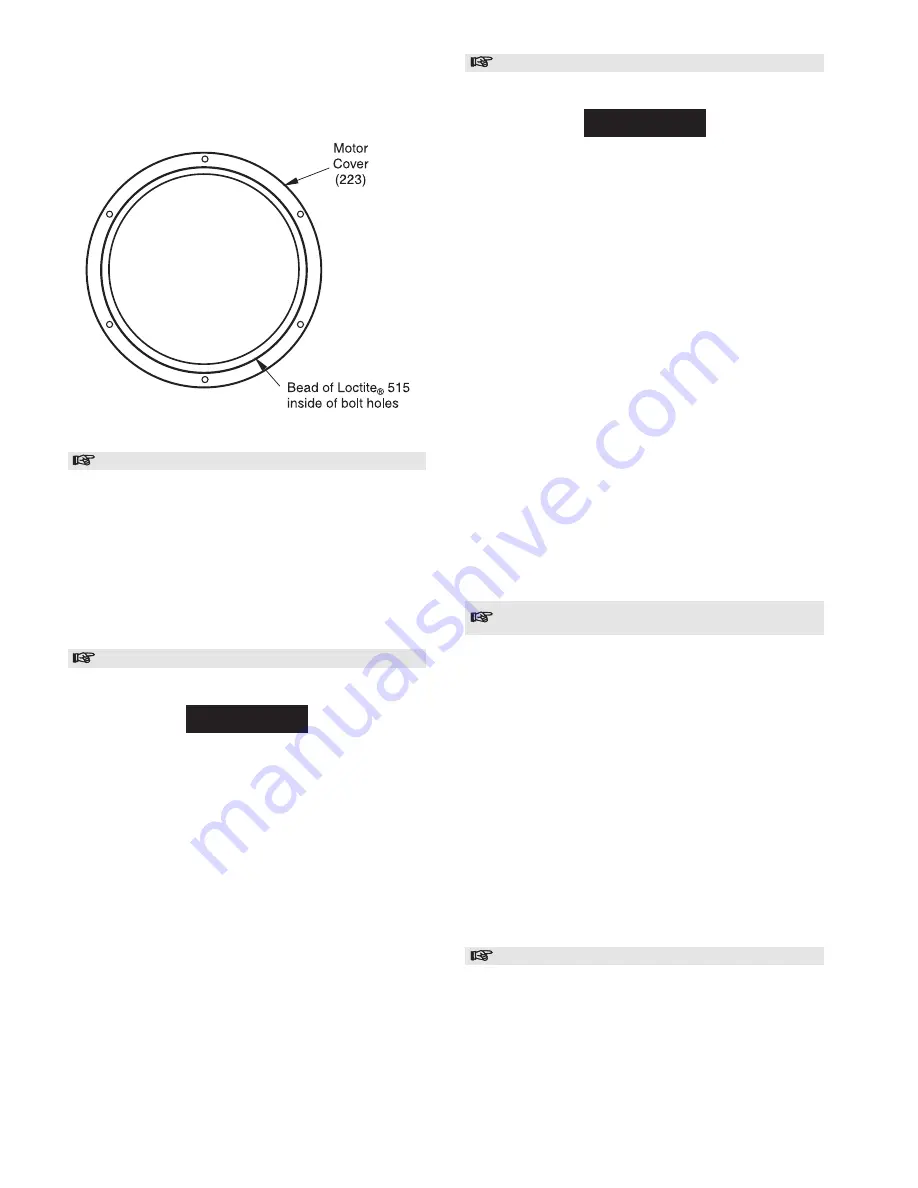

Place cover assembly onto motor housing.

3.

Apply Loctite

®

242 to capscrews (224) and insert into

motor housing. Tighten to 40-50 in lb. (4.5-5.7 Nm).

Motor Cover Sealant Placement

(Dwg. MHP1318)

Mounting Motor To Winch

1.

Assemble exhaust manifold (233) by inserting capscrews

(224) through exhaust manifold and into motor housing.

Tighten to 40-50 in lb. (4.5-5.7 Nm).

2.

Wrap a nylon sling around motor housing and, using a

suitable hoist, slide motor assembly straight onto drive

shaft (61), twisting motor to engage splines on shaft.

3.

Align bolt holes, with air inlet on motor housing facing up.

Insert capscrews (221) through motor flange into adapter

(71) and tighten to 33-36 ft lb. (45-49 Nm).

4.

Attach muffler assembly (234) to exhaust manifold (233).

Control Valve Assembly

Refer to Dwg. MHP1314.

NOTICE

• During assembly align parts using match marks made

during disassembly.

1.

Install seal rings (315) on each end of valve body (316).

2.

Install valve body (316) into valve bushing (314).

3.

Install valve body retainer (305) with two capscrews (302)

and lockwashers (304). Torque capscrews to 25 ft lbs (34

Nm).

4.

Install flange (318) and gasket (317) and secure using

capscrews (302) and lockwashers (304). Torque capscrews

to 25 ft lbs (34 Nm).

5.

If removed, reinstall spring retaining stud (306) and torque

to 25 ft lbs (34 Nm).

6.

Install spring (303) and handle (300) on square shaft of

valve body (316). The spring (303) ends must straddle the

spring retaining stud (306) on throttle handle (300). Install

roll pin (301).

7.

Check throttle handle moves fully left and right without

sticking or binding. Throttle handle should center, by

spring force, automatically when released.

Installation of Control Valve and Inlet Manifold

Refer to Dwg. MHP1314.

NOTICE

• Manifold (606) and cover (607) are bonded together and

thermoplastic coated. If these components are separated then

they must be re-bonded prior to assembly. Refer to the

following:

Bonding Procedure:

a.

Clean mating surfaces of manifold (606) and cover

(607). Apply a thin layer of Loctite

®

515 to one

mating surface.

b.

Insert capscrews (614) through cover. These are just

guides at this time.

c.

Place cover onto manifold. Ensure bolt holes are

aligned. Clamp cover and manifold together and allow

sealant to cure.

d.

Refer to ‘Thermoplastic Coated Parts Assembly’ to

repair removed coating.

1.

Verify spool locating pin (613) is straight and installed in

manifold (606). Position gasket (611) and manifold/cover

assembly on motor housing. Install four capscrews (614) to

clamp parts to motor housing (220). Torque capscrews to

108-112 in lb. (12-13 Nm).

2.

Mount control valve assembly (260) and gasket (321) to

cover such that handle is toward winch drum. Install four

capscrews (331) and torque to 33-36 ft lb. (45-49 Nm).

3.

Connect brake line to swivel elbow fitting (319) on control

valve housing.

4.

Connect air supply line to control valve.

Installation of Remote Control Valve and Inlet

Manifold

Optional feature. Refer to Dwg. MHP1304.

1.

Verify spool locating pin (613) is straight and installed in

manifold (606). Position gasket (611) and manifold on

motor housing. Apply Loctite

®

242 to capscrew (614)

threads and install four capscrews to clamp manifold to

motor housing (220). Torque capscrews to 108-112 in lb.

(12-13 Nm).

2.

Apply Loctite

®

515 to valve assembly mounting surface

and install on cover (607). Apply Loctite

®

242 to capscrew

(615) threads and install four capscrews to clamp cover to

valve assembly. Torque capscrews to 55 ft lb (74 Nm).

3.

Apply Loctite

®

515 to manifold surface and install cover

and valve assembly. Position assembly such that valve

exhaust port is away from the winch drum. Install four

capscrews (608) and torque to 21 ft lb. (28 Nm).

4.

Connect brake line to connector fitting (621).

5.

Connect pendant hoses to valve fittings.

6.

Connect air supply line to control valve.

Emergency Stop Assembly

Optional feature. Refer to Dwg. MHP1331.

1.

Place bracket (527) on bottom of shut off valve (522).

Locate bracket long end on the shut off valve air out side.

Loosely install capscrews (528).

2.

Place bracket (529) on bottom of shut off valve. Locate

bracket face to rear (as viewed from muffler side) of shut

off valve. Install capscrews (531).

3.

Tighten capscrews (528) and (531).

Summary of Contents for FA2A

Page 8: ...7 ...

Page 38: ...37 WINCH CROSS SECTION DRAWING ...

Page 39: ...38 WINCH ASSEMBLY PARTS DRAWING ...

Page 41: ...40 MOTOR ASSEMBLY PARTS DRAWING ...

Page 47: ...46 CONTROL VALVE ASSEMBLY PARTS DRAWING ...

Page 49: ...48 REMOTE PENDANT AND CONTROL VALVE ASSEMBLY PARTS DRAWING ...

Page 53: ...52 EMERGENCY STOP AND OVERLOAD ASSEMBLY PARTS DRAWING ...

Page 55: ...54 REMOTE EMERGENCY STOP AND OVERLOAD ASSEMBLY PARTS DRAWING ...