15

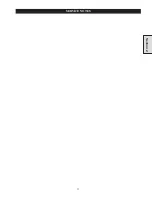

7.

Gently spread the ends of the brake band apart and slide it off

the brake drum and onto the winch drum.

(Dwg. MHP1033)

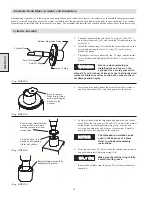

8.

Gently spread the ends of the brake band apart far enough to

clear the winch drum barrel diameter and take it off the drum.

(Dwg. MHP1045)

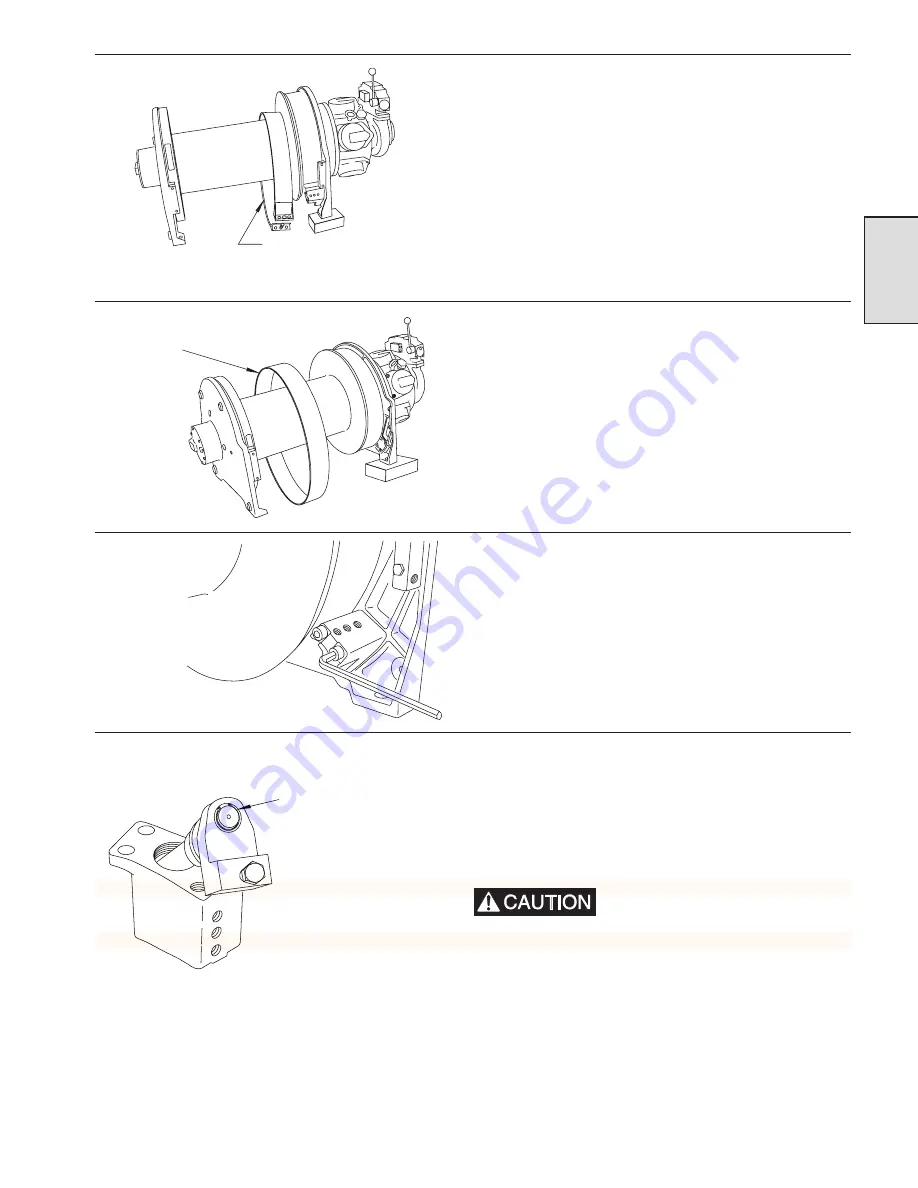

9.

Using a 10 mm allen wrench, loosen and remove the two long

and two short capscrews (107 and 112) that fasten the brake

bracket (106) to the winch upright.

(Dwg. MHP1042)

10. If needed, the ‘O’ rings and bearings can be removed from the

brake bracket. The ‘O’ rings are easily removed with a blunt

scribe or a screwdriver, and the small needle bearing (140) can

easily be removed by pressing it out. Removal of the larger

needle bearing (138) is only required if the bearing housing is

cracked or chipped or if the rollers are damaged. Removal in

this case can be accomplished using a punch, driven against the

bearing outer race.

This may shatter the race and

cause pieces to scatter. Be sure to

wear safety glasses.

11. Remove the retainer ring (132) that holds the cam plate to the

eccentric shaft, and remove the washer (133), cam plate (131),

and sleeve bearing (134). This completes the disassembly of

the manual band brake.

(Dwg. MHP1040)

Section 2

Move the Brake Band onto the

Winch Drum barrel diameter.

Remove the Brake Band

from the Winch Drum barrel

diameter.

Remove the Brake Bracket

from the Winch Upright.

Remove the Retainer Ring

and Washer to remove

the Cam Plate from the

Eccentric Shaft and take

off the Sleeve Bearing.

Summary of Contents for FA5A

Page 10: ...10 DISC BRAKE PARTS DRAWING Dwg MHP0667 Dwg MHP0630 One Way Clutch Detail Section 1...

Page 19: ...19 Section 2 SERVICE NOTES...

Page 54: ...54 REDUCTION GEAR ASSEMBLY PARTS DRAWING Dwg MHP1221 Section 5...

Page 57: ...57 SERVICE NOTES...

Page 58: ...58 SERVICE NOTES...

Page 59: ...59 SERVICE NOTES...