16

Manual Band Brake Assembly and Installation

NOTICE

Band brake installation is most

easily done with the motor end of

the winch blocked up approxi-

mately 10 cm [4 inches]. Be sure to support the winch

securely so that it cannot move while it is being serviced.

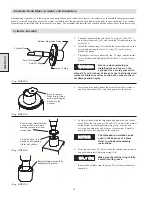

1.

If the needle bearings (138 and 140) were removed, press them

back into place. Lubricate them by packing with a good quality

EP grease, and install and lubricate the ‘O’ ring dirt exclusion

seals with the same grease.

2.

Using the two long (107) and two short (112) capscrews,

fasten the brake bracket (106) to the winch uprights. Torque

the capscrews to 45-50 Nm (33-36 ft. lbs.)

(Dwg. MHP1094)

3.

Gently spread the ends of the brake band (104) apart and slip

the band over the winch drum barrel diameter.

4.

Gently spread the ends of the brake band, and slip it over the

flange and onto the brake surface.

(Dwg. MHP1095)

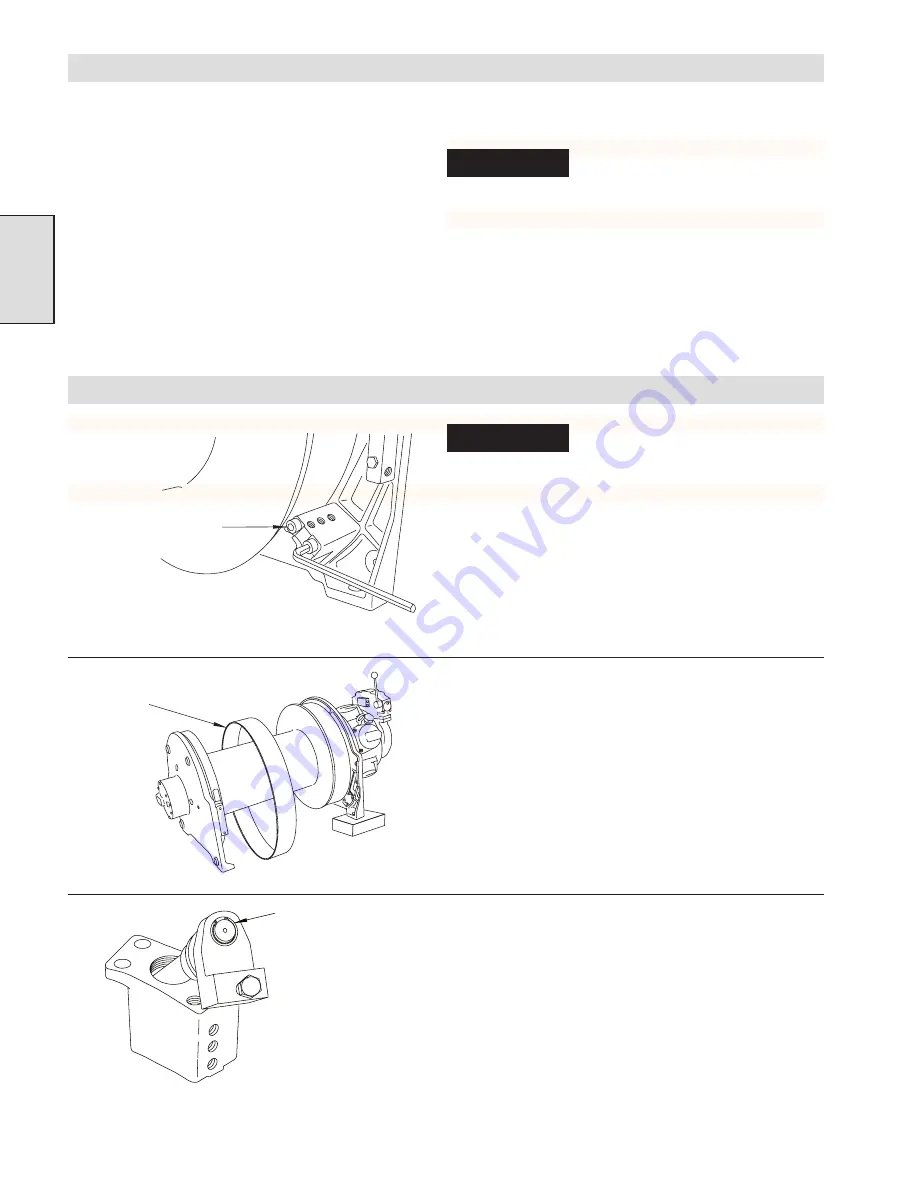

5.

Lubricate the sleeve bearing (134) with EP grease, and install

on the eccentric shaft (135) followed by the cam plate (131),

the washer (133), and the retainer ring (132).

6.

Insert the eccentric shaft into the brake bracket .

(Dwg. MHP1092)

Inspection

Section 2

1.

Check the sleeve bearing allows free movement of the cam

plate. Replace if worn oval by more than 0.76 mm (0.03

inch).

2.

Inspect the eccentric shaft bearing surfaces for galling and

flat spots.

3.

Make sure the two bearings in the brake bracket allow the

eccentric shaft to move smoothly and easily. Replace the

bearings if any of the needles are damaged or if the outer

shells are cracked or chipped.

4.

Examine the adjustment bolt threads and the locking pellet

for any damage. Replace them if the adjustment bolt is bent

or the threads are damaged, or if the pellet is tight in the

threaded locking screw hole.

5.

Make sure that the rubber spacer between the brake band

and the brake bracket is still pliable and has not hardened

or cracked.

6.

Replace the brake band if the friction surface measures less

than 1.5 mm (1/16 inch) thick anywhere on the band.

NOTICE

Do not wash the brake band in

cleaning solvent. Wipe clean, or

if needed use a commercially

available brake cleaner.

7.

Check the tubular spacers for signs of collapsing. If any of

them are buckling or collapsing, replace them as a set. They

should measure 28.3 to 28.8 mm (1.115 to 1.135 inches).

8.

Check for any signs of wear on the hardened flat washers that

retain the tubular spacers. If they are wearing, replace them as

a set.

9.

Inspect the ‘O’ rings (the dirt exclusion seals) for damage.

Replace if necessary.

Install the Brake Bracket

onto the Winch Upright.

Install the Brake Band

onto the Winch Drum barrel

diameter.

Install the Sleeve

Bearing, Cam Plate,

Washer and Retainer

Ring on the

Eccentric Shaft.

Summary of Contents for FA5A

Page 10: ...10 DISC BRAKE PARTS DRAWING Dwg MHP0667 Dwg MHP0630 One Way Clutch Detail Section 1...

Page 19: ...19 Section 2 SERVICE NOTES...

Page 54: ...54 REDUCTION GEAR ASSEMBLY PARTS DRAWING Dwg MHP1221 Section 5...

Page 57: ...57 SERVICE NOTES...

Page 58: ...58 SERVICE NOTES...

Page 59: ...59 SERVICE NOTES...