29

8.

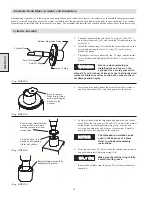

To assemble the plunger, place the roller (116) inside the

plunger body (114), and then insert the pin (115). Before

installing the pin, thoroughly coat the pin, roller, and plunger

with Lubriplate Mo-Lith NO. 2 (or equivalent) grease.

(Dwg. MHP0985)

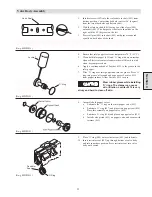

Automatic Band Brake Assembly and Installation

1.

Gently spread the ends of the brake band (104) apart, and slip

the band onto the winch drum barrel diameter.

(Dwg. MHP1097)

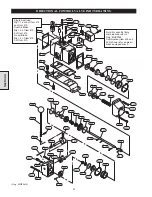

2.

Using the two long (107) and two short (112) capscrews,

fasten the brake bracket (106) on to the winch upright. Torque

the capscrews to 45-50 Nm (33-36 ft. lbs).

3.

Gently spread the ends of the brake band and slip it over the

flange and onto the brake surface.

(Dwg. MHP1099)

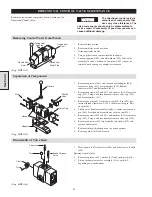

4.

Place the small spring (113) in the end of the plunger, and slip

the plunger (114) into the brake bracket (106) bolted onto the

frame. Make sure that the threaded end of the plunger faces the

open end of the bracket. (Brake bracket pictured unmounted.)

(Dwg. MHP1250)

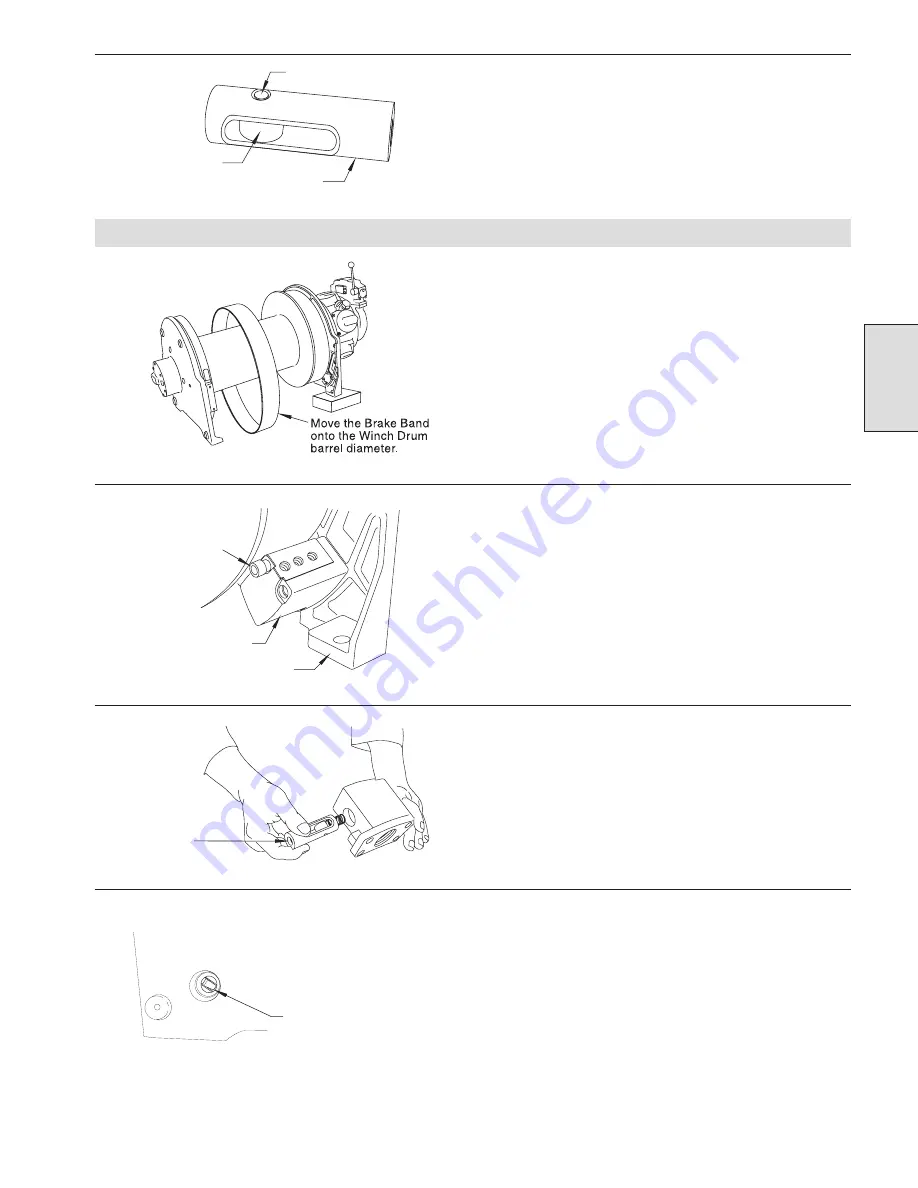

5.

Look through the hole in the upright and position the plunger

so that the slot in the plunger is aligned with the hole.

(Dwg. MHP1032)

Section 3

Pin

Roller

Plunger Body

Brake Bracket

Capscrew

Winch Upright

Threaded end of

Plunger must face

the open end of

the Bracket.

Make sure that the slot

in the Plunger is lined up

with the hole in the

Winch Upright.

Summary of Contents for FA5A

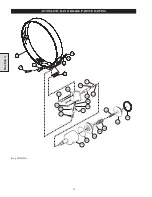

Page 10: ...10 DISC BRAKE PARTS DRAWING Dwg MHP0667 Dwg MHP0630 One Way Clutch Detail Section 1...

Page 19: ...19 Section 2 SERVICE NOTES...

Page 54: ...54 REDUCTION GEAR ASSEMBLY PARTS DRAWING Dwg MHP1221 Section 5...

Page 57: ...57 SERVICE NOTES...

Page 58: ...58 SERVICE NOTES...

Page 59: ...59 SERVICE NOTES...