38

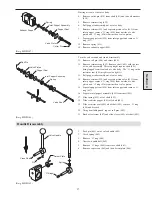

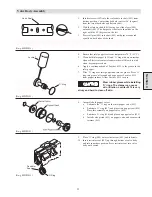

Inspection

4.

Set springs on a flat surface, springs should stand straight up.

If springs have any abnormal appearance, replace.

5.

Ensure that valve components are kept clean during repair. Dirt

or other contaminates can cause damage to new parts.

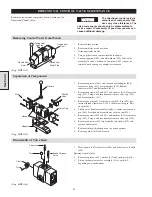

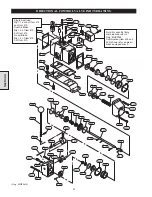

Directional Control Valve Assembly and Installation

During control valve assembly lubricate all ‘O’ rings with DOW CORNING #111 lubricant.

NOTICE

When installing new end caps,

valve body or valve adapter, clean

all threaded holes with a tap (to

remove any burrs or debris). Also remove any coating

from machined surfaces to ensure a proper fit.

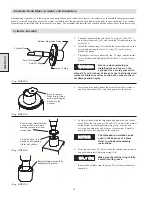

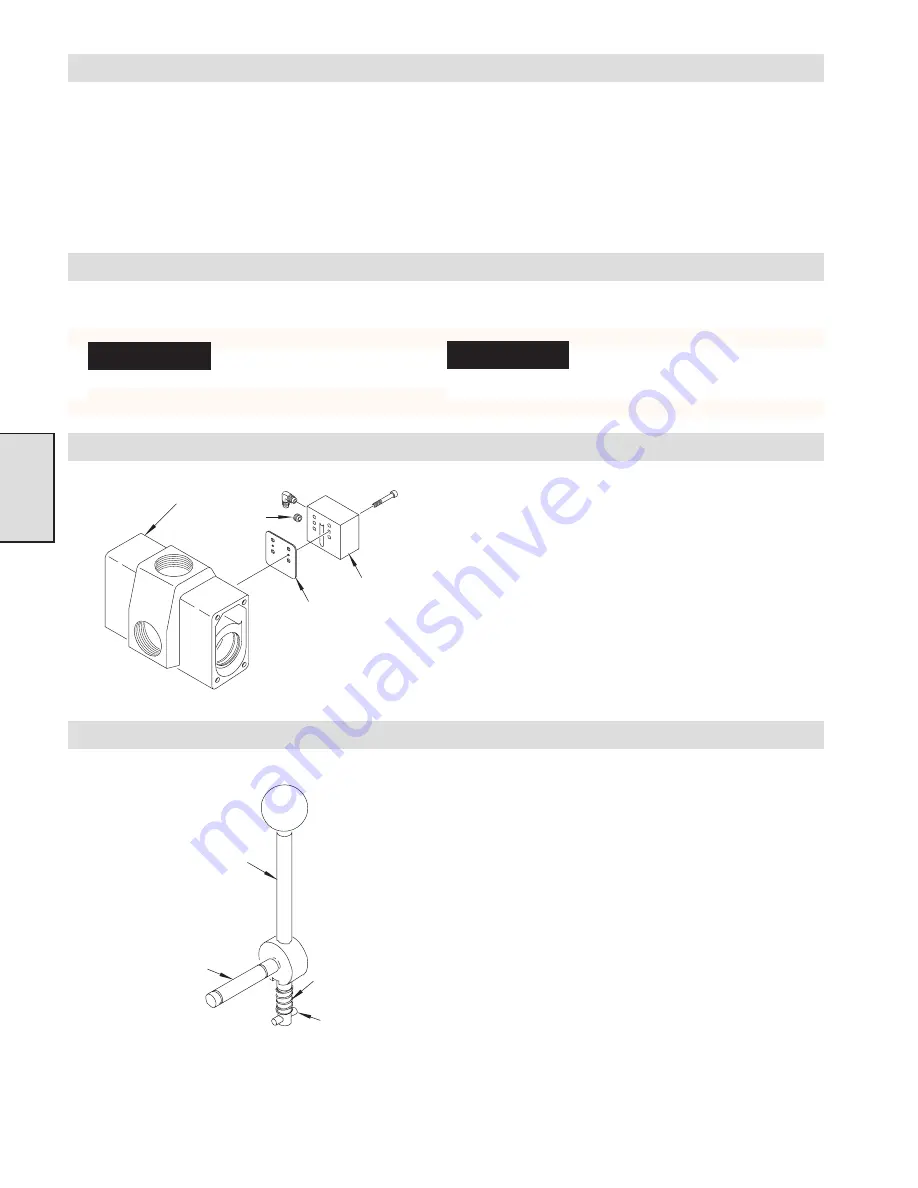

Shuttle Valve Assembly

1.

Place a bead of pipe sealant around threads of fittings installed

in lower port on shuttle valve body (479) and tighten.

2.

Place capscrews (418) into shuttle valve body(479) and slide

gasket (419) onto the capscrews. Match capscrews to mounting

holes in valve body (410) insert and tighten to 24 to 30 inch lb.

(8.9 - 3.0 Nm).

(Dwg. MHP1150)

Handle Assembly

1.

Apply Loctite

®

242 on threads of valve handle (449). Screw

handle ball (469) onto valve handle (449) and tighten.

2.

Slide ‘O’ ring (460) onto valve handle (449) and lubricate.

Insert this assembly into cross shaft (461).

3.

Slide spring (462) onto lower portion of valve handle (449).

4.

Press pin (463) into valve handle. Pin should protrude about

1/16 inch (1.6 mm) from one side. Long side of pin should fit

into slot in the cross shaft and not bind when moved up and

down.

(Dwg. MHP1151)

Section 4

1.

Inspect the bores in the valve body and end caps, for

pitting, scratches or other signs of abnormal wear. Clean

and lightly hone.

2.

Replace ‘O’ rings in all components disassembled. Replace

any steel components (not the valve body) that are showing

sign of corrosion.

3.

Inspect springs, looking for signs of cracks, bulging, or

corrosion.

NOTICE

DOW CORNING #111 lubricant

is the ONLY factory authorized

lubricant for this valve. Use of

other lubricants may cause valve malfunctions.

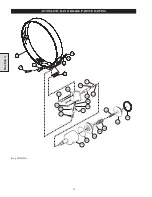

Valve

Body

Plug

Gasket

Shuttle

Valve

Valve Handle

Cross Shaft

Spring

Pin

Summary of Contents for FA5A

Page 10: ...10 DISC BRAKE PARTS DRAWING Dwg MHP0667 Dwg MHP0630 One Way Clutch Detail Section 1...

Page 19: ...19 Section 2 SERVICE NOTES...

Page 54: ...54 REDUCTION GEAR ASSEMBLY PARTS DRAWING Dwg MHP1221 Section 5...

Page 57: ...57 SERVICE NOTES...

Page 58: ...58 SERVICE NOTES...

Page 59: ...59 SERVICE NOTES...