27

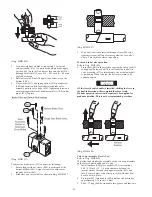

a.

Lubricate ‘O’ ring on poppet valve (423).

b.

Lubricate ‘O’ ring (427) and place it on poppet seat

(428). Place this assembly on poppet valve (423).

c.

Lubricate ‘O’ ring (426) and place it on poppet valve

(423).

d.

Put valve piston (431) on poppet valve and secure with

retainer ring (432).

e.

Place ‘O’ ring (430) in groove in valve piston and

lubricate.

8.

Slide poppet assembly onto shaft (401) and insert cotter pin

(414) in end of shaft to hold components. Do not bend

cotter pin ends at this time.

NOTICE

• Pendant Pilot Valves do not use cotter pin (414). For these

units, use a suitable cotter pin to temporarily contain

components on the shaft. The pin will be removed in a

following step.

9.

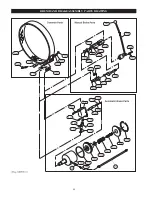

Lubricate ‘O’ ring (404), place on restrictor seat (403) and

insert assembly from the bottom of valve body and into

position. Refer to Dwg. MHP1023. Press restrictor seat into

groove in valve body until seated.

10. Install shaft (401) assembly in valve body (410) from side

with installed restrictor seat (403). Carefully install to

prevent sleeve (408) or pins (405) from damaging seat as

they pass through.

11. Align poppet seat with valve body and, using fingers, press

poppet seat into valve body.

(Dwg. MHP1023)

12. Secure in place using retainer ring (429). Remove cotter pin

installed in step 8.

NOTICE

• The flats on shaft (401) must be facing the left (or valve)

side of the valve body (410).

13. On opposite side of valve body, slide exhaust poppet (420)

onto shaft (401). Press into valve body.

14. Install spring (422).

15. Slide poppet assembly (423) onto shaft (401).

NOTICE

• Pendant Pilot Valves do not use cotter pin (414). For these

units, use a suitable cotter pin to temporarily contain

components on the shaft. The pin will be removed in a

following step.

16. Align poppet seat with valve body and, using fingers, press

poppet seat into valve body.

17. Secure in place using retainer ring (429).

NOTICE

• Install pin (406) in step 18 only enough to determine

clearance requirements of step 19. Do not fully install pin

until directed.

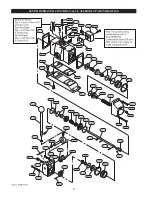

18. On lever operated control valves install pin (406) in shaft

(401) on the handle end of valve. This is the side of the

valve that the restrictor poppet (402) and restrictor seat

(403) are located. On pendant operated control valves pin

(406) will be installed on both ends of shaft (401).

19. Measure clearance between end of poppet assembly (423)

and pin (406). Using shims (444) attain a clearance of 0.03

- 0.05 inch (0.8 - 1.3 mm) between poppet assembly and

pin.

20. When clearance is established, press pin down until pin

protrudes below shaft 0.380 (+/- 0.01) inch (9.7 [+/- 0.3]

mm).

Brake Release Valve Installation and Adjustment

Refer to Dwgs. MHP0653 (Pendant Pilot Operated Valve) or

MHP0654 (Lever Operated Valve) and MHP1227.

NOTICE

• Valve assembly (413) shaft body is longer on one side of

middle groove than the other. Correct placement of valve

assembly is with the longer shaft section located towards the

bottom of the valve body (410). The shorter section will

protrude up, through the valve body.

• To adjust brake release valve ensure sleeve (408) is loose on

shaft (401). If not loose, back off (turn counterclockwise)

setscrew (407).

1.

Rotate sleeve (408) to place the longer edge on top. Refer

to Dwg. MHP1024.

2.

Using gentle hand pressure to prevent damage to the valve

assembly (413) shaft body, press valve assembly down until

ball is in firm contact with sleeve (408).

CAUTION

• When using sealants care must be taken to use only enough

to effectively do the job. Excess sealant can drip onto internal

components and harden resulting in erratic winch operation

or control problems.

Summary of Contents for force5 FA5A-LAK1

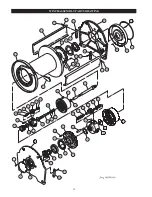

Page 34: ...34 WINCH ASSEMBLY PARTS DRAWING ...

Page 36: ...36 MOTOR ASSEMBLY PARTS DRAWING ...

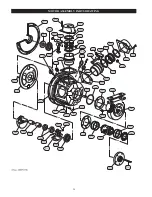

Page 38: ...38 DISC BRAKE ASSEMBLY PARTS DRAWING ...

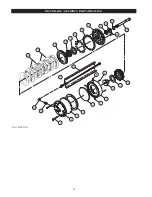

Page 40: ...40 DRUM BAND BRAKE ASSEMBLY PARTS DRAWING ...

Page 42: ...42 LEVER OPERATED CONTROL VALVE ASSEMBLY PARTS DRAWING ...

Page 44: ...44 PENDANT OPERATED PILOT CONTROL VALVE ASSEMBLY PARTS DRAWING ...

Page 48: ...48 SHUTTLE VALVE ASSEMBLY PARTS DRAWING ...

Page 50: ...50 EMERGENCY STOP AND OVERLOAD ASSEMBLY PARTS DRAWING ...

Page 52: ...52 OPEN FRAME FACE WINCH ASSEMBLY PARTS DRAWING ...

Page 57: ...57 WINCH LABEL TAG LOCATION AND PART NUMBER REFERENCE DRAWING ...