4

SAFE OPERATING INSTRUCTIONS

9.

Be certain the load is properly seated in the saddle of the

hook. Do not support the load on the tip of the hook.

10. Do not “side pull” or “yard”.

11. Always ensure that you, and all other people, are clear of

the path of the load. Do not lift a load over people.

12. Never use the winch for lifting or lowering people, and

never allow anyone to stand on a suspended load.

13. Ease the slack out of the wire rope when starting a lift or

pull. Do not jerk the load.

14. Do not swing a suspended load.

15. Do not leave a suspended load unattended.

16. Never operate a winch with twisted, kinked or damaged

wire rope.

17. Pay attention to the load at all times when operating the

winch.

18. Never use the wire rope as a sling.

19. After use, or when in a non-operational mode, the winch

should be secured against unauthorized and unwarranted

use.

The following warnings and operating instructions have been

adapted in part from American National (Safety) Standard

ASME B30.7 and are intended to avoid unsafe operating

practices which might lead to injury or property damage.

Ingersoll-Rand recognizes that most companies who use

winches have a safety program in force at their facility. In the

event that some conflict exists between a rule set forth in this

publication and a similar rule already set by an individual

company, the more stringent of the two should take precedence.

Safe Operating Instructions are provided to make an operator

aware of dangerous practices to avoid and are not necessarily

limited to the following list. Refer to specific sections in the

manual for additional safety information.

1.

Only allow people, trained in safety and operation of this

product, to operate and maintain this winch.

2.

Only operate a winch if you are physically fit to do so.

3.

When a “DO NOT OPERATE” sign is placed on the

winch, or controls, do not operate the winch until the sign

has been removed by designated personnel.

4.

Before each shift, the operator should inspect the winch for

wear and damage. Never use a winch that inspection

indicates is worn or damaged.

5.

Never lift a load greater than the rated capacity of the

winch. See labels attached to winch or refer to

“SPECIFICATIONS” section.

6.

Keep hands, clothing, etc., clear of moving parts.

7.

Never place your hand in the throat area of a hook or near

wire rope spooling onto or off of the winch drum.

8.

Always rig loads properly and carefully.

WARNING

Welded mountings

can fail.

Can cause severe

injury or death.

Do not weld, braze or

solder to winch.

71270813

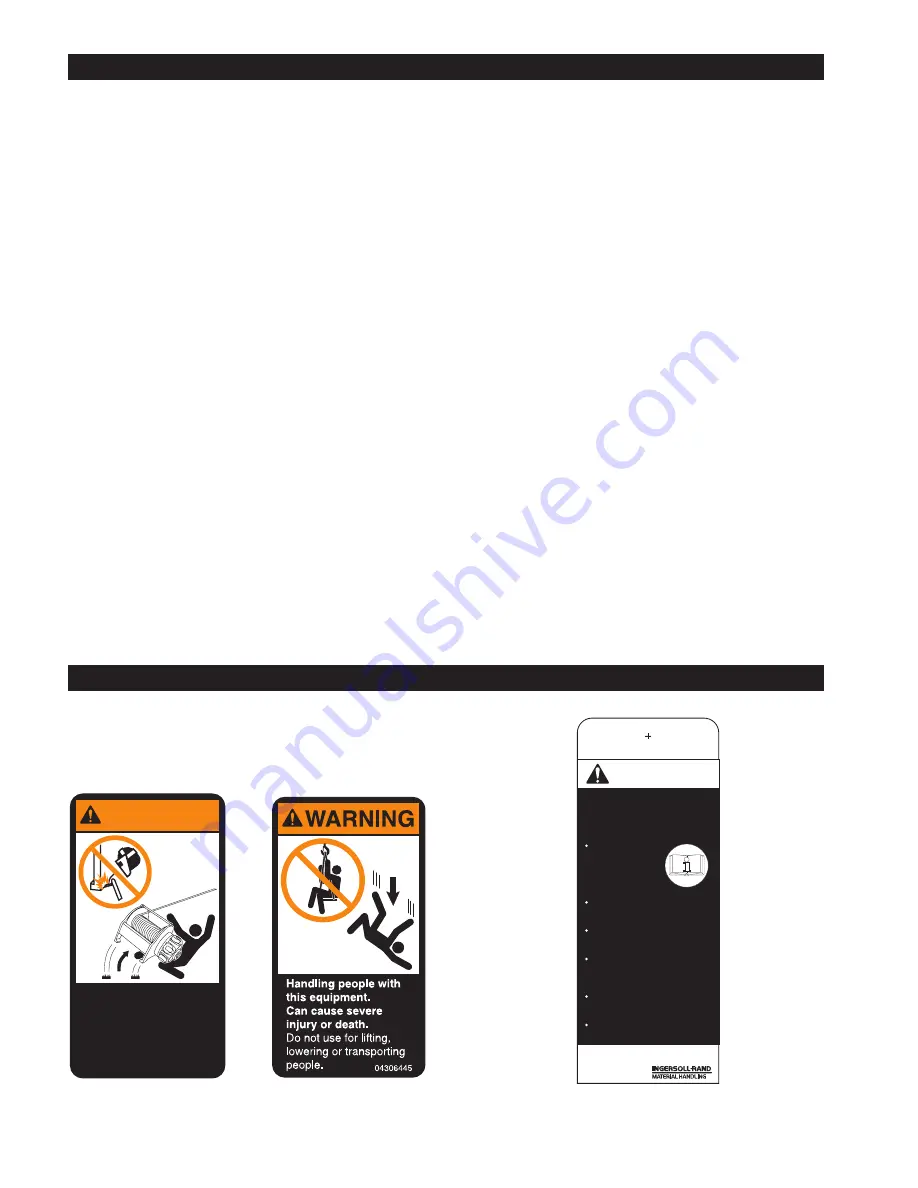

WARNING LABELS AND TAG

Each unit is shipped from the factory with the warning labels

and tag shown. If the labels or tag are not attached to your unit,

order new labels and tag and install. See the parts list for the

part numbers. Labels and tag shown smaller than actual size.

WARNING

?

Read the latest edition of ASME B30.7.

Comply with other federal, state and local rules.

P/N 71056410/A

for winches

Failure to follow these

warnings may result in

death, severe injury or

property damage:

Do not operate

this winch before

reading operation

and maintenance

manual.

Do not lift people or loads

over people.

Do not lift more than rated

load.

Do not allow less than three

wraps of wire rope to remain

on drum at all times.

Do not operate a damaged

or malfunctioning winch.

Do not remove or obscure

warning labels.

Summary of Contents for force5 FA5A-LAK1

Page 34: ...34 WINCH ASSEMBLY PARTS DRAWING ...

Page 36: ...36 MOTOR ASSEMBLY PARTS DRAWING ...

Page 38: ...38 DISC BRAKE ASSEMBLY PARTS DRAWING ...

Page 40: ...40 DRUM BAND BRAKE ASSEMBLY PARTS DRAWING ...

Page 42: ...42 LEVER OPERATED CONTROL VALVE ASSEMBLY PARTS DRAWING ...

Page 44: ...44 PENDANT OPERATED PILOT CONTROL VALVE ASSEMBLY PARTS DRAWING ...

Page 48: ...48 SHUTTLE VALVE ASSEMBLY PARTS DRAWING ...

Page 50: ...50 EMERGENCY STOP AND OVERLOAD ASSEMBLY PARTS DRAWING ...

Page 52: ...52 OPEN FRAME FACE WINCH ASSEMBLY PARTS DRAWING ...

Page 57: ...57 WINCH LABEL TAG LOCATION AND PART NUMBER REFERENCE DRAWING ...