4

Form MHD56349 Edition 1

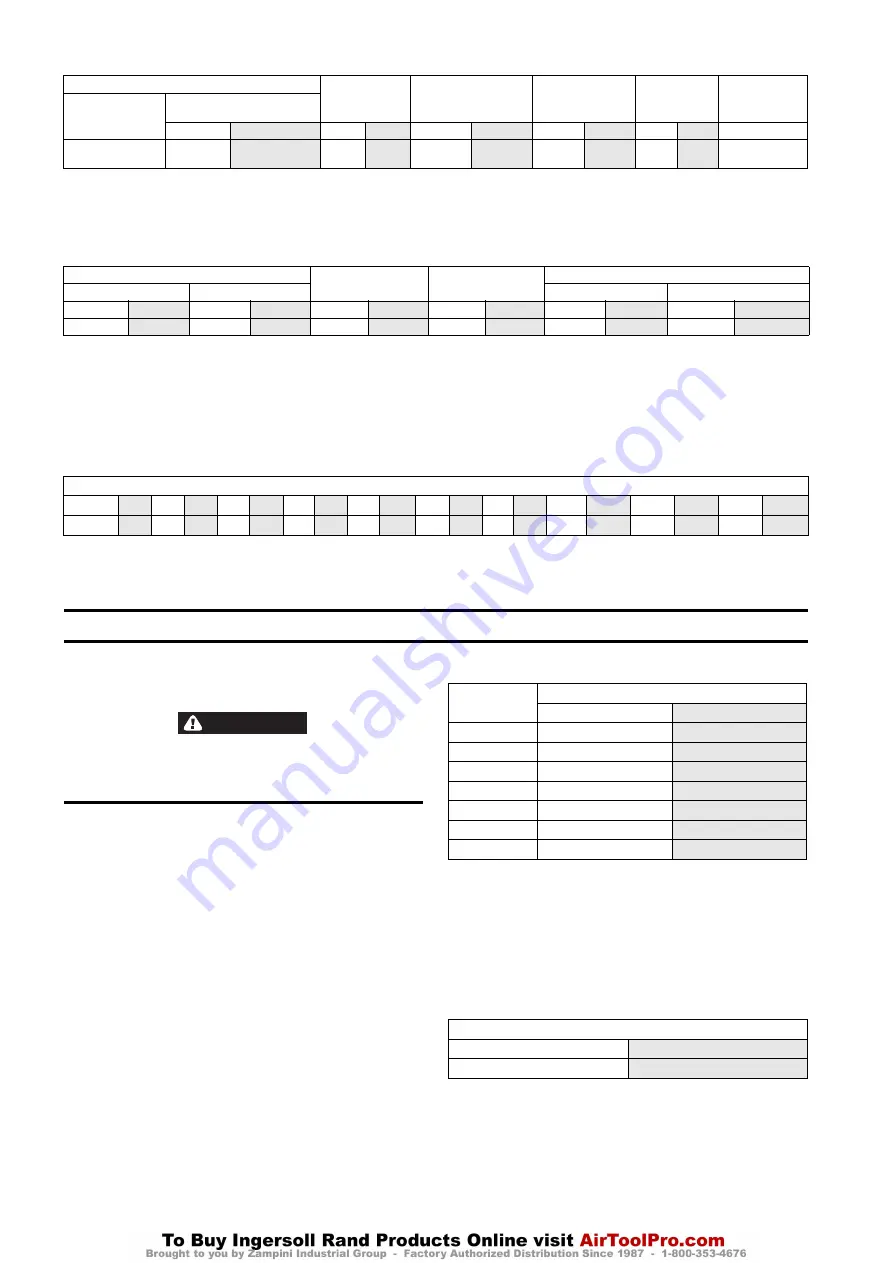

Table 2: Specifications

INSTALLATION

Prior to installing the winch, carefully inspect it for possible shipping damage.

Winches are supplied fully lubricated from the factory.

Check oil levels and adjust as necessary before operating winch. Refer to

“LUBRICATION” section for recommended oils and lubrication intervals.

CAUTION

• Owners and users are advised to examine specific, local or other regulations,

including American National Standards Institute and/or OSHA Regulations

which may apply to a particular type of use of this product before installing or

putting winch to use.

Mounting

Refer to Dwg. MHP0133 on page 11,

A.

Drum; Table 5 on page 4 and Table 6 on

page 4.

Care must be taken when moving, positioning or mounting the winch. In most cases,

lifting lugs have been provided to assist in handling the winch. If lug locations are

improper for your specific installation, great care should be taken to ensure that

winch, when lifted, will be properly balanced. Determine weight of winch by referring

to “SPECIFICATIONS” section. Add weight of wire rope and other installed options as

necessary. Lift winch 3 to 4 inches (75 to 100 mm) off ground. Verify winch is

balanced and secure before continuing lift. Mount winch so axis of drum is horizontal

and that motor vent cap is not more than 15° off top vertical center. If winch is to

be mounted in an inverted position, motor case must be rotated to position vent cap

to the top.

1. The winch mounting surface must be flat and of sufficient strength to handle

rated load plus weight of winch and attached equipment. An inadequate

foundation may cause distortion or twisting of winch uprights and side rails

resulting in winch damage.

2. Make sure mounting surface is flat to within 0.005 inch (0.127 mm) per inch of

drum length. Shim if necessary. Refer to Table 5 on page 4.

3. Mounting bolts must be Grade 8 or better. Use self-locking nuts or nuts with

lockwashers. Refer to Table 6, “Mounting Bolts,” on page 4.

4. Tighten 3/4 inch (18 mm) mounting bolts evenly and torque to 380 ft lbs (515

Nm) for dry thread fasteners. If fasteners are plated, lubricated or a thread

locking compound is used, torque to 280 ft lbs (380 Nm).

5. Maintain a fleet angle between sheave and winch of no more than 1-1/2°. The

lead sheave must be on a center line with drum and, for every inch (25 mm) of

drum length, be at least 1.6 feet (0.5 metre) from the drum. Refer to Product

Safety Information Manual.

6. Do not weld to any part of winch.

Air System

Air Motor Pipe

Inlet Size

Minimum Air System

Hose Size (inside

diameter)

Drum

Barrel Diameter

Drum Flange

Diameter

Sound Pressure

Level

Rated Operating

Pressure

Air Consumption

(at rated pressure and load)

scfm

cu.m/min

inch

mm

inch

mm

inch

mm

inch

mm

dBA

90 psig (630 kPs/6.3

bar)

700

20

1.25

32

1.5

38

15

381

27

686

89

Sound measurements have been made in accordance with ISO 11201, ISO 3744-3746 and ISO 4871 test specifications for sound from pneumatic equipment. Readings shown

are based on the average noise level of each winch configuration, proportionate to the utilized time in a regular cycle.

Lpc (Peak Sound Pressure) does not exceed 130 dB.

Performance based on 90 psig (6.3 bar/630 kPs) operating pressure.

Table 3: Rated Performance (at Rated Pressure/Volume)

Full Drum Lifting Capacity *

Stall Pull

Required Rope Size **

Drum Rope Storage Capacity ***

Personnel

Utility

Personnel

Utility

lbs

kgs

lbs

kgs

lbs

kg

in

mm

ft

m

ft

m

4,400

2,000

7,040

3,200

24,000

10,909

5/8

16

1,024

312

1,456

444

* Man Rider rating of 4,400 lbs (2,000 kg) is based on requirements of ANSI A10.22 [8:1 design factor with 5/8 inch (16 mm) wire rope]. Utility rating of 7,040 lbs (3,200 kg)

is based on requirements of ASME B30.7 [5:1 design factor with 5/8 inch (16 mm) wire rope].

** Rope construction: Only 6 x 19, 6 x 37 classification, or rotation-resistance ropes, all with IWRC, shall be used.

*** Man Rider wire rope storage is based on a winch with a 24 inch (610 mm) diameter drum flange and on ANSI A10.22 standards which require the top layer to be at least

2 inches (51 mm) below the drum flange diameter. Utility wire rope storage is based on a winch with a 19 inch (483 mm) diameter drum flange and on ASME/ANSI B30.7

standards which require the top layer to be at least 1/2 inch (13 mm) below the drum flange diameter.

Refer to sales literature for winch drum wire rope storage capacities on other drum lengths.

Table 4: Available Drum Lengths

Drum Lengths

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

---

---

12

305

16

406

20

508

24*

610*

30

762

36

915

40**

1016**

42**

1067**

50**

1270**

* Standard Length

** Special, contact factory

Table 5: Mounting Surface Tolerance

Drum

Length

Mounting Surface Minimum Flatness

inch

mm

8

0.04

1.02

12

0.06

1.52

16

0.08

2.03

20

0.10

2.54

24

0.12

3.05

30

0.15

3.81

36

0.18

4.57

Table 6: Mounting Bolts

Mounting Bolts

inch

mm

3/4

18