ENGLISH

10. LOAD CHAIN END ANCHORS. Ensure both ends of load chain are securely attached.

Secure if loose, repair if damaged, replace if missing.

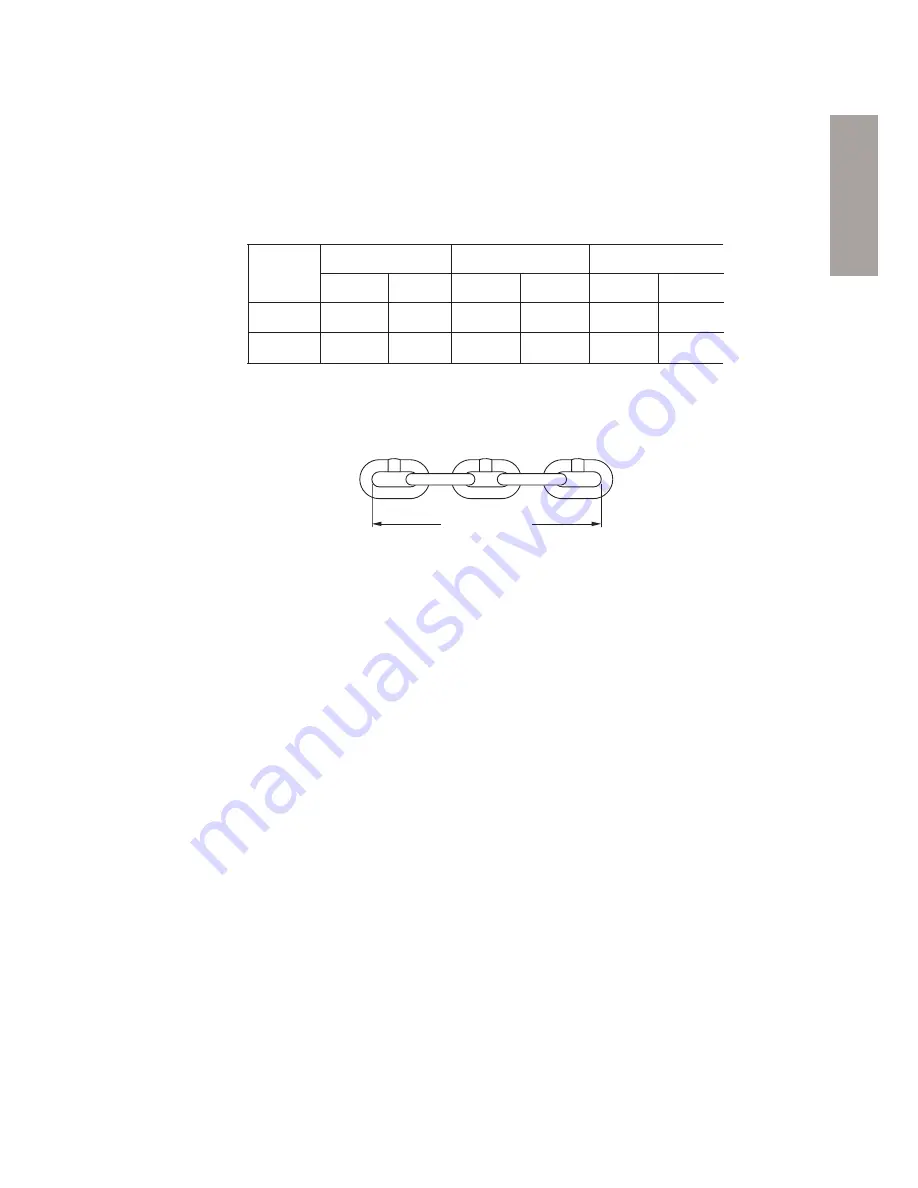

11. LOAD CHAIN. Measure the chain for stretching by measuring across eleven link sections all

along the chain (ref. Dwg. MHTPA0041) paying particular attention to the most reeved links.

When any eleven links in the working length reach or exceed the discard length shown in Table

2, replace the entire chain. Always use a genuine

Ingersoll-Rand

Material Handling replacement

chain.

Table 2

Model

No.

Chain Wire Size

Normal Length

Discard Length

in

mm

in

mm

in

mm

MLK

1/4

6,35

8448

214,6

8,57

218

HLK

3/8

9,52

9108

231,3

9,24

234

Zinc plated load chain is available for standard hoists. Always use

stainless steel load chain on HL1000KR Spark Resistant Hoists.

Gauge Length

(Dwg. MHTPA0041)

12. CHAIN CONTAINER. Check for damage or excessive wear and that chain container is

securely attached to the hoist. Secure or replace if necessary.

13. LIMIT ASSEMBLY. Check throttle lever moves freely. To limit hook downward travel the

loop in the slack chain side must contact the throttle lever. To limit hook upward travel the

bottom hook block must contact the throttle lever.

To test “UP” and “DOWN” travel limits first run hoist slowly with no load to verify proper

function. Repeat test at full speed with no load to verify proper function.

Hoists Not in Regular Service

1.

A hoist which has been idle for a period of one month or more, but less than one year, should

be given an inspection conforming with the requirements of “Frequent Inspection” before being

placed into service.

2.

A hoist that has been idle for a period of more than one year should be given a complete

inspection conforming with the requirements of “Periodic Inspection” before being placed into

service.

3.

Standby hoists should be inspected at least semiannually in accordance with the requirements

of “Frequent Inspection.” In abnormal operating conditions equipment should be inspected at

shorter intervals.

12