Book 43212455 (11/03)

27

SECTION 8 - MAINTENANCE

Any unauthorized modification or failure to

maintain this equipment may make it unsafe and

out of factory warranty.

If performing

more than visual inspections, disconnect

driver engine battery cables and open manual

blow-down valve.

Use extreme care to avoid contacting hot

surfaces (heat exchange and piping, air receiver

and air discharge piping, etc.).

Never operate this machine with any guards

removed.

Inch and metric hardware was used in the design

and assembly of this unit. Consult the parts

manual for clarification of usage.

GENERAL

In addition to periodic inspections, many of the

components in this unit require periodic servicing

to provide maximum output and performance.

Servicing may consist of pre-operation and post-

operation procedures to be performed by the

operating or maintenance personnel. The primary

function of preventive maintenance is to prevent

failure, and consequently, the need for repair.

Preventive maintenance is the easiest and the

least expensive type of maintenance. Maintaining

your unit and keeping it clean at all times will

facilitate servicing.

SCHEDULED MAINTENANCE

The maintenance schedule is based on normal

operation of the unit. In the event unusual

environmental operating conditions exist, the

schedule should be adjusted accordingly.

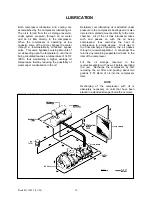

COMPRESSOR OIL LEVEL

The oil level should be checked before the unit is

operated. The optimum operating level is midway

of the sight tube on the side of the receiver tank.

See the decal beside the sight tube. If the oil level

is not in the “OK” range, make appropriate

corrections (Add or Drain). A totally filled sight

tube in which the level is not visible indicates an

over-full condition and requires that oil be drained.

AIR CLEANER

This unit is equipped with AIR FILTER

RESTRICTION INDICATOR on the front panel,

serving both compressor inlet air cleaners.

This should be checked daily during operation. If

the indicator shows (red) with the unit operating at

full speed, servicing of the cleaner element is

necessary.

Also weekly, squeeze the rubber valve (pre-

cleaner dirt dump) on each air cleaner housing to

ensure that they are not clogged.

If flagged, the air filter restriction indicator must be

reset after unit is shut down and the air cleaners

are serviced. Reset by pushing button on top of

indicator.

To service the air cleaners on all units proceed as

follows:

1.

Loosen outer wing nut and remove cover.

Remove element.

2. Inspect air cleaner housing for any

condition that might cause a leak and

correct as necessary.

3.

Wipe inside of air cleaner housing with a

clean, damp cloth to remove any dirt

accumulation, especially in the area where

the element seals against the housing.

4.

Inspect element by placing a bright light

inside and rotating slowly. If any holes or

tears are found in the paper, discard this

element. If no ruptures are found, the

element can be cleaned.

5. If a new air filter element is to be used

check it closely for shipping damage.

CAUTION

WARNING

Summary of Contents for HP600CMH

Page 8: ...Book 43212455 11 03 8 IMPORTANT SAFETY INSTRUCTIONS ...

Page 9: ...Book 43212455 11 03 9 ...

Page 10: ...Book 43212455 11 03 10 ...

Page 14: ...Book 43212455 11 03 14 fold ...

Page 37: ...Book 43212455 11 03 37 ...

Page 44: ......