Book 43212455 (11/03)

36

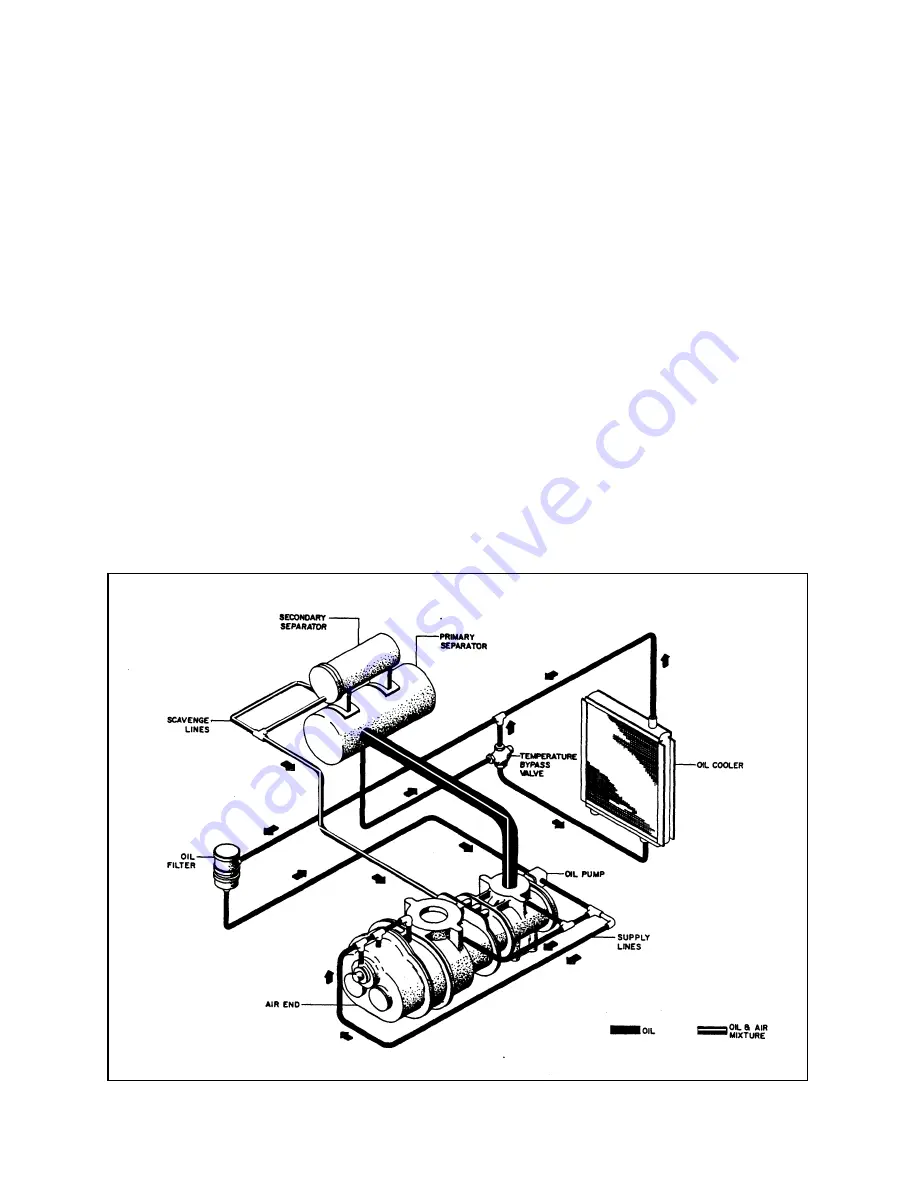

LUBRICATION

Both compressor lubrication and cooling are

accomplished by the compressor lubricating oil.

The oil is forced from the oil storage reservoir,

under system pressure, through an oil cooler

and an oil filter directly to the compressor.

When the compressor is operating at low

capacity, some of the oil may bypass the cooler

through a thermostatically controlled bypass

valve. This valve bypasses varying amounts of

oil, depending upon the temperature, until the oil

being circulated reaches a temperature of 185

°

F

(85

°

C) thus maintaining a higher average oil

temperature thereby reducing the possibility of

water vapor condensation in the oil.

Typical Lubricating and Cooling Oil System

Relatively cool lubricating oil is admitted under

pressure to the compressor bearings and is also

injected in metered amounts, directly to the rotor

chamber. All of the oil thus introduced mixes

with, and passes on with the air being

compressed, thus removing the heat of

compression to a large degree. On its way to

the final discharge connection, the air passes

through a receiver/separator. A scavenger line

returns any remaining separated oil back to the

inlet of the compressor.

Fill the oil storage reservoir in the

receiver/separator with new oil before operating

the unit. Recharge the compressor by first

removing the air filter and pouring about two

gallons (7.57 liters) of oil into the compressor

inlet.

NOTE

Recharging of the compressor with oil is

absolutely necessary on units that have been

placed in extended storage (6 months or more).

Summary of Contents for HP600CMH

Page 8: ...Book 43212455 11 03 8 IMPORTANT SAFETY INSTRUCTIONS ...

Page 9: ...Book 43212455 11 03 9 ...

Page 10: ...Book 43212455 11 03 10 ...

Page 14: ...Book 43212455 11 03 14 fold ...

Page 37: ...Book 43212455 11 03 37 ...

Page 44: ......