STARTING/OPERATING

•

Close service valve.

•

Engage hydraulic pump at lowest possible driver

speed

Do NOT engage compressor motor at driver speed above

idle. Damage to compressor motor, pump, or other

driveline component scan occur.

•

Flip RUN/STOP switch to RUN position.

•

Increase driver speed to compressor operation rated

speed.

•

Allow compressor to run unloaded five (5) to ten (10)

minutes.

•

Compressor is now ready to furnish compressed air

when service valve is opened.

STOPPING

•

Close air service valve(s).

•

Allow the unit to run at “no load” for 3 to 5 minutes to

reduce the compressor temperature.

•

Flip RUN/STOP switch to STOP position.

•

Disengage hydraulic pump.

NOTE: Once the drive motor stops, the automatic

blow-down valve will begin to relieve all pressure from

the receiver separator system.

Never allow the unit to sit stopped with pressure in the

receiver separator system. As a precaution, after the

automatic blowdown period (3 minutes), open the manual

blow-down valve.

EQUIPMENT PROTECTION

NOTE: Do NOT wire around or bypass a shutdown

sensor or switch.

This unit is protected by a shutdown switch at the following

location:

High Discharge Air Temperature

(1) In the end of the separator tank.

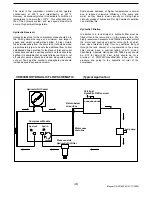

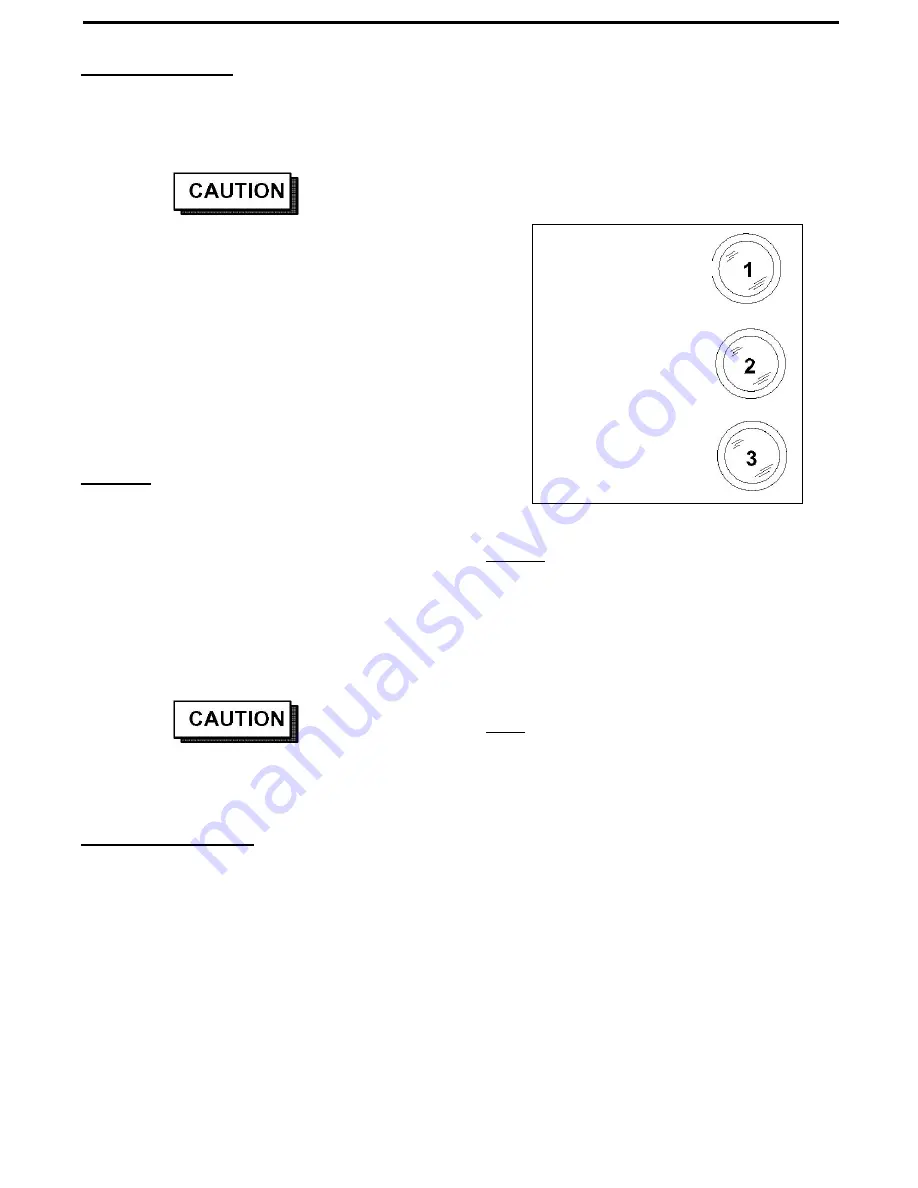

GAUGE PANEL

Operating Instruments

On Panel

1. Compressor Discharge Pressure Gauge – Indicates

pressure in receiver tank, psig (kPa).

2. Discharge Air Temperature Gauge – Indicates dis-

charge air temperature in °F and °C. Normal

operating range: 185°F/85°C to 248°F/120°C.

3. Hour meter – Indicates elapsed unit operating time.

Inside

4. Air Filter Restriction Indicator – Indicates compressor

air cleaner restriction.

Normal operation (<20-in. H2O), green flag.

Needs service, (>20-in. H2O), red flag.

(Indicator located at base of inlet filter. Visible

through grille at discharge end of machine).

(

25

)

Manual P/N 22189203 (01/17/2005)

Summary of Contents for HP60CMH

Page 6: ... 6 Manual P N 22189203 01 17 2005 ...

Page 7: ... 7 Manual P N 22189203 01 17 2005 ...

Page 8: ... 8 Manual P N 22189203 01 17 2005 ...

Page 9: ... 9 Manual P N 22189203 01 17 2005 9 Manual P N 22189203 01 17 2005 ...

Page 10: ... 10 Manual P N 22189203 01 17 2005 10 Manual P N 22189203 01 17 2005 ...

Page 41: ... 41 Manual P N 22189203 01 17 2005 ...

Page 43: ... 43 Manual P N 22189203 01 17 2005 ...

Page 44: ...22173538 44 Manual P N 22189203 01 17 2005 ...

Page 45: ...UNLOADER ASSEMBLY 45 Manual P N 22189203 01 17 2005 ...

Page 46: ...Separator Tank 46 Manual P N 22189203 01 17 2005 ...

Page 47: ... 47 Manual P N 22189203 01 17 2005 ...

Page 48: ... 48 Manual P N 22189203 01 17 2005 ...

Page 49: ...AIR OIL HYDRAULIC PIPING 49 Manual P N 22189203 01 17 2005 ...

Page 50: ...AIR OIL HYDRAULIC PIPING 50 Manual P N 22189203 01 17 2005 ...

Page 52: ... 52 Manual P N 22189203 01 17 2005 Wiring Diagram ...