Summary of Contents for HP60CMH

Page 6: ... 6 Manual P N 22189203 01 17 2005 ...

Page 7: ... 7 Manual P N 22189203 01 17 2005 ...

Page 8: ... 8 Manual P N 22189203 01 17 2005 ...

Page 9: ... 9 Manual P N 22189203 01 17 2005 9 Manual P N 22189203 01 17 2005 ...

Page 10: ... 10 Manual P N 22189203 01 17 2005 10 Manual P N 22189203 01 17 2005 ...

Page 41: ... 41 Manual P N 22189203 01 17 2005 ...

Page 43: ... 43 Manual P N 22189203 01 17 2005 ...

Page 44: ...22173538 44 Manual P N 22189203 01 17 2005 ...

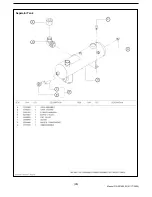

Page 45: ...UNLOADER ASSEMBLY 45 Manual P N 22189203 01 17 2005 ...

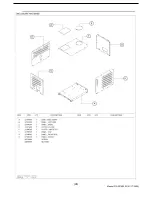

Page 46: ...Separator Tank 46 Manual P N 22189203 01 17 2005 ...

Page 47: ... 47 Manual P N 22189203 01 17 2005 ...

Page 48: ... 48 Manual P N 22189203 01 17 2005 ...

Page 49: ...AIR OIL HYDRAULIC PIPING 49 Manual P N 22189203 01 17 2005 ...

Page 50: ...AIR OIL HYDRAULIC PIPING 50 Manual P N 22189203 01 17 2005 ...

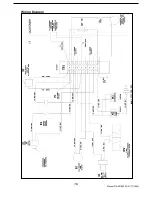

Page 52: ... 52 Manual P N 22189203 01 17 2005 Wiring Diagram ...