18-CD34D1-5-EN 13

INSTALLER’S GUIDE

VENTING INTO A MASONRY CHIMNEY

If the chimney is oversized, the liner is inadequate, or flue-

gas condensation is a problem in your area, consider using the

chimney as a pathway or chase for type “B” vent or flexible vent

liner. If flexible liner material is used, size the vent using the “B”

vent tables, then reduce the maximum capacity by 20% (multiply

0.80 times the maximum capacity).

Internal Masonry Chimneys

Venting of fan assisted appliances into a lined, internal masonry

chimney is allowed only if it is common vented with at least one

natural draft appliance; OR, if the chimney is lined with type “B”,

double wall vent or suitable flexible liner material (See Table 7).

▲

WARNING

!

The chimney liner must be thoroughly inspected

to insure no cracks or other potential areas for

flue gas leaks are present in the liner. Liner leaks

will result in early deterioration of the chimney.

Failure to follow this warning could result in

carbon monoxide poisoning or death.

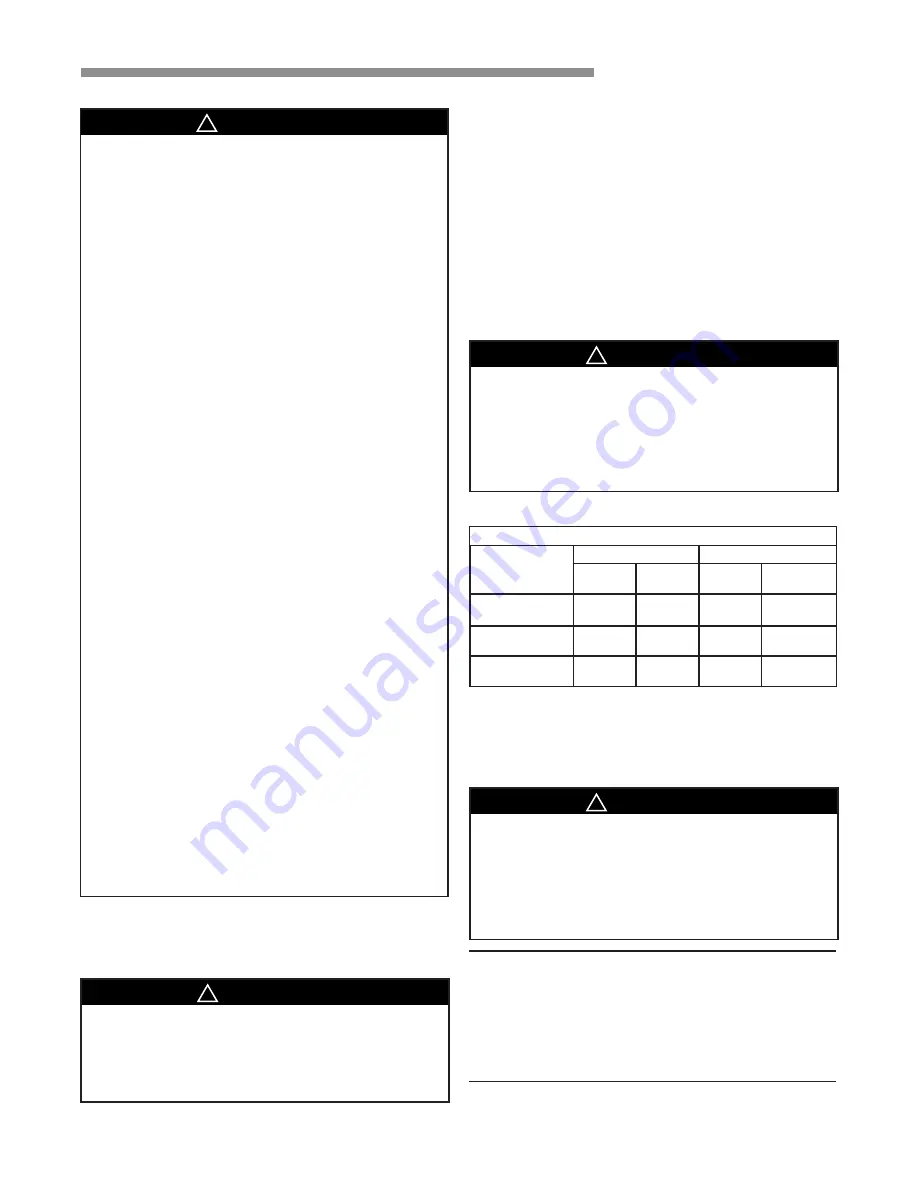

TABLE 7

MASONRY CHIMNEY VENTING

Tile Lined Chimney

Chimney Lining

Type Furnace

Internal

External

“B” Vent

Flexible

Metal Liner

Single Fan

Assist

No

No

Yes

Yes*

Fan Assist

+ Fan Assist

No

No

Yes

Yes*

Fan Assist

+ Natural

Yes

No

Yes

Yes*

* Flexible chimney liner size is determined by using the type “B” vent size

for the available BTUH input, then reducing the maximum capacity by 20%

(multiply maximum capacity times 0.80). The minimum capacity is the same

as shown in the “B” vent tables.

External Masonry Chimney

▲

WARNING

!

CARBON MONOXIDE POISONING HAZARD

This masonry chimney kit shall NOT be installed

on any furnaces with 40,000 BTU/H inputs or any

downflow models. Failure to follow this warning

could result in carbon monoxide poisoning,

personal injury, or death.

NOTE: Masonry Chimney Kit BAYVENT800B may be used

with these furnaces (Upflow model furnaces 60,000 BTU/H

and above only) to allow venting into an external masonry

chimney. Refer to BAYVENT800B Installer's Guide for

application requirements. The following section does not

apply if BAYVENT800B (Masonry Chimney Kit) is used. All

instructions with the kit must be followed.

▲

WARNING

!

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for

each appliance connected to the venting system

being placed into operation could result in carbon

monoxide poisoning or death.

The following steps shall be followed for each appliance

connected to the venting system being placed into

operation, while all other appliances connected to the

venting system are not in operation:

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and

horizontal pitch, as required in the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 or the CAN/CGA B149

Installation Codes and these instructions. Determine

that there is no blockage or restriction, leakage,

corrosion and other deficiencies which could cause

an unsafe condition.

3. As far as practical, close all building doors and

windows and all doors between the space in which

the appliance(s) connected to the venting system are

located and other spaces of the building.

4. Close fireplace dampers.

5. Turn on clothes dryers and any appliance not

connected to the venting system. Turn on any exhaust

fans, such as range hoods and bathroom exhausts,

so they are operating at maximum speed. Do not

operate a summer exhaust fan.

6. Follow the lighting instructions. Place the appliance

being inspected into operation. Adjust the thermostat

so appliance is operating continuously.

7. If improper venting is observed during any of the

above tests, the venting system must be corrected

in accordance with the National Fuel Gas Code,

ANSI Z221.1/NFPA 54 and/or CAN/CGA B149

Installation Codes.

8. After it has been determined that each appliance

connected to the venting system properly vents where

tested as outlined above, return doors, windows,

exhaust fans, fireplace dampers and any other gas-

fired burning appliance to their previous conditions of

use.

The furnace shall be connected to a factory built chimney or

vent complying with a recognized standard, or a masonry or

concrete chimney lined with a lining material acceptable to

the authority having jurisdiction.

▲

WARNING

!

Furnace venting into an unlined masonry chimney

or concrete chimney is prohibited.

Failure to follow this warning could result in

property damage, personal injury, or death.