18-CD37D1-2-EN

21

Installer’s Guide

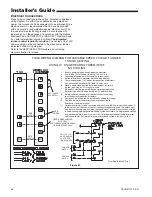

VENT

COMBUSTION

AIR

VENT

VENT

PLATE

VENT

CAP

12" MINIMUM

TO OVERHANG

MAINTAIN 12" MINIMUM CLEARANCE

ABOVE HIGHEST ANTICIPATED SNOW LEVEL

OR GRADE WHICHEVER IS GREATER

SCREWS

(4 req.)

ANCHORS

(4 req.)

7.2"

3.2"

Figure 32. BAYVENT200B

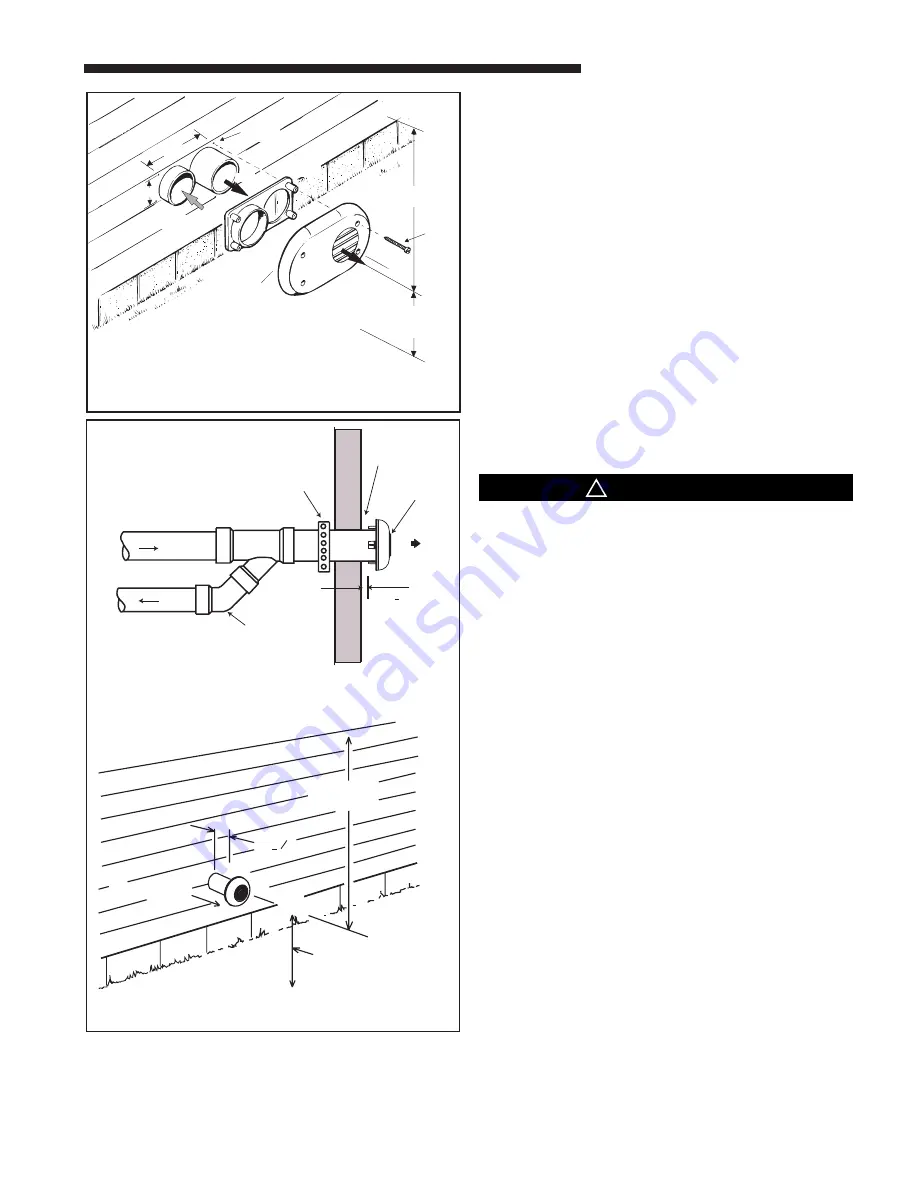

RAIN CAP

COMBUSTION AIR

STRAP

(FIELD SUPPLIED)

COMBUSTION

AIR

VENT

ELBOW

(FIELD

SUPPLIED)

VENT

1" + 1/2"

Figure 33

BAYAIR30AVENTA

(Sidewall)

Important:

The Commonwealth of Massachusetts requires

compliance with regulation 248 CMR 4.00 and 5.00 for

installation of through – the – wall vented gas appliances as

follows:

For all side wall horizontally vented gas fueled equipment

installed in every dwelling, building or structure used in whole

or in part for residential purposes, including those owned

or operated by the Commonwealth and where the side wall

exhaust vent termination is less than seven (7) feet above

finished grade in the area of the venting, including but not

limited to decks and porches, the following requirements

shall be satisfied:

1. INSTALLATION OF CARBON MONOXIDE

DETECTORS. At the time of installation of the side

wall horizontal vented gas fueled equipment, the

installing plumber or gasfitter shall observe that

a hard wired carbon monoxide detector with an

alarm and battery back-up is installed on the floor

level where the gas equipment is to be installed.

In addition, the installing plumber or gasfitter shall

observe that a battery operated or hard wired

carbon monoxide detector with an alarm is installed

on each additional level of the dwelling, building or

structure served by the side wall horizontal vented

gas fueled equipment. It shall be the responsibility

of the property owner to secure the services of

qualified licensed professionals for the installation of

hard wired carbon monoxide detectors

HORIZONTAL VENTING THROUGH WALL

These Furnaces may be installed as direct vent (as

shipped) or as nondirect vent. Installation must conform

to national, state, and local codes.

The BAYVENT200B and BAYAIR30AVENTA vent & inlet termi-

nals kits must be located at least 12" minimum above normally

expected snow accumulation level.

Avoid areas where staining or condensate drippage may be a

problem.

Location of the vent/wind terminal should be chosen to meet

the requirements of Figure 30 for either direct or non-direct

vent applications.

PITCH —

Venting through the wall must maintain 1/4" per foot

pitched upward to insure that condensate drains back to the

Furnace.

FLUE GAS DEGRADATION —

The moisture content of the

flue gas may have a detrimental effect on some building mate-

rials. This can be avoided by using the roof or chimney venting

option. When wall venting is used on any surface that can be

affected by this moisture, it is recommended that a corrosion

resistant shield (24 inches square) be used behind the vent

terminal. This shield can be wood, plastic, sheet metal, etc.

Also, silicone caulk all cracks, seams and joints within 3 feet of

the vent terminal.

▲

CAUTION

!

The vent for this appliance shall not terminate

(1) Over public walkways; or

(2) Near soffit vents or crawl space vents or other areas

where condensate or vapor could create a nuisance or

hazard or cause property damage; or

(3) Where condensate vapor could cause damage or could be

detrimental to the operation of regulators, relief valves.

or other equipment.

For Canadian applications, horizontal vent termination

kits must meet ULC-S636.

For Canadian applications, horizontal vent termination

kits must meet ULC-S636.

COMBUSTION

AIR

12" MIN TO

OVERHANG

1" + "

VENT

1 2

MAINTAIN 12 IN.

MINIMUM CLEARANCE

ABOVE HIGHEST

ANTICIPATED SHOW

LEVEL OR GRADE

WHICH EVER IS GREATER