10

INSTALLATION

Prior to installing the winch, carefully inspect it for possible

shipping damage.

Winches are supplied fully lubricated from the factory. Check

oil levels and adjust as necessary before operating winch. Refer

to “LUBRICATION” section for recommended oils.

CAUTION

• Owners and users are advised to examine specific, local or

other regulations, including American National Standards

Institute and/or OSHA Regulations which may apply to a

particular type of use of this product before installing or

putting winch to use.

Mounting

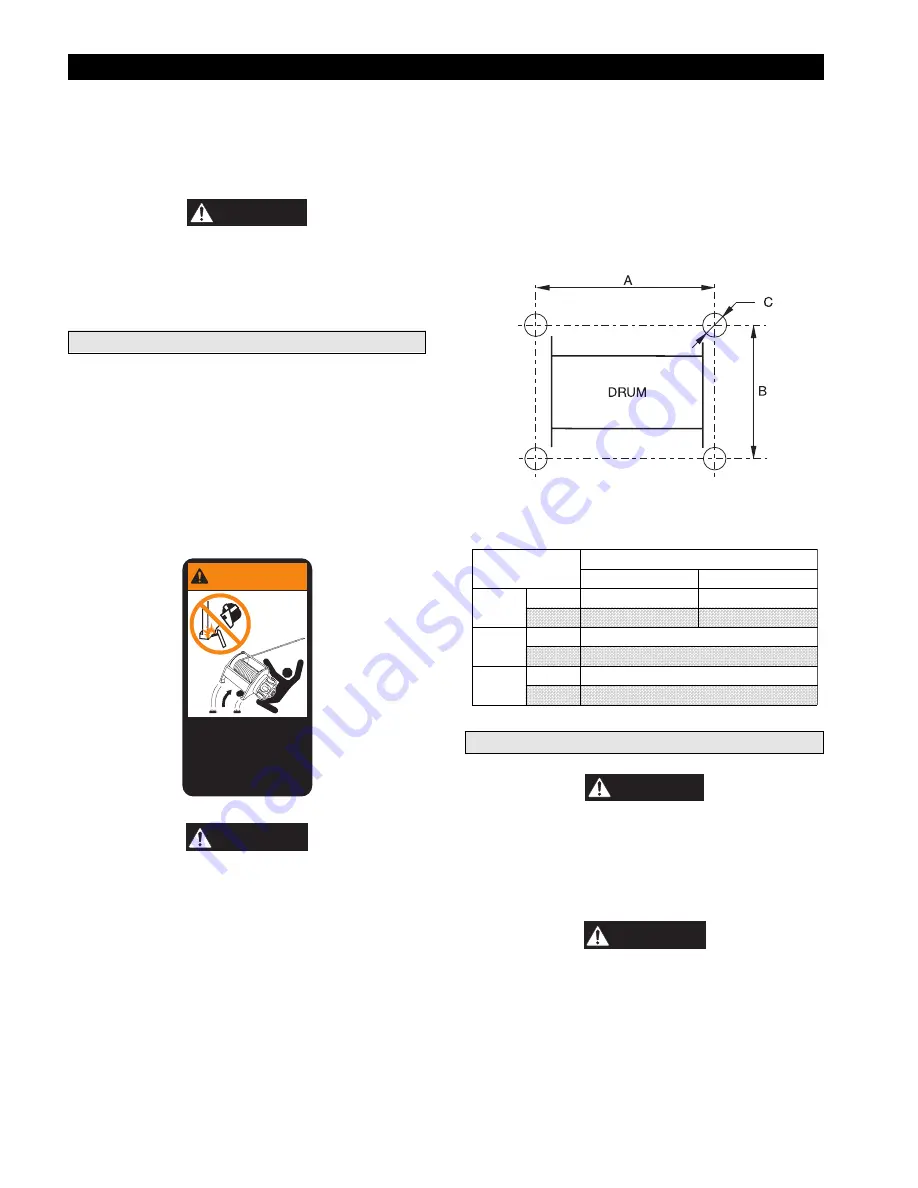

Refer to Dwg. MHP0124 and Table 1.

Care must be taken when moving, positioning or mounting the

winch. Ensure that the winch, when lifted, will be properly

balanced. Determine the weight of the winch by referring to the

“SPECIFICATIONS” section. Lift the winch 3 to 4 inches (75

to 100 mm) off the ground. Verify winch is balanced and secure

before continuing lift.

Mount the winch so the axis of the drum is horizontal and that

the motor vent cap is not more than 15° off top vertical center. If

the winch is to be mounted in an inverted position, the motor

case must be rotated to position the vent cap at the top and

adequate clearance must be provided for control valve operation.

WARNING

Welded mountings

can fail.

Can cause severe

injury or death.

Do not weld, braze or

solder to winch.

71270813

WARNING

• Winch frame material is not suitable for welding. FA5AMR

winches must only be mounted by bolting to a suitable

foundation. Do not attempt to mount the winch by welding to

a foundation structure.

1.

The winch mounting surface must be flat and of sufficient

strength to handle the rated load plus the weight of the

winch and attached equipment. An inadequate foundation

may cause distortion or twisting of the winch uprights and

side rails resulting in winch damage.

2.

Make sure the mounting surface is flat to within 1/32 inch

(0.8 mm). Shim if necessary.

3.

Mounting bolts must be 3/4 inch-NC (18 mm) Grade 8 or

better. Use self-locking nuts or nuts with lockwashers.

4.

Tighten mounting bolts evenly and torque to 380 ft lbs (515

Nm) for dry thread fasteners. If the fasteners are plated,

lubricated or a thread locking compound is used, torque to

280 ft lbs (380 Nm).

5.

Maintain a fleet angle between the lead sheave and winch

of no more than 1-1/2°. The lead sheave must be on a

center line with the drum and, for every inch (25 mm) of

drum length, be at least 1.6 feet (0.5 metre) from the drum.

Refer to Dwg. MHP0498.

6.

Do not weld to any part of the winch.

(Dwg. MHP0124)

Table 1: Mounting Bolt Hole Dimensions

Dimension

Drum Length (inches)

12

24

“A”

in.

17.89

29.89

mm

455

760

“B”

in.

22

mm

559

“C”

in.

0.81

mm

21

Wire Rope

CAUTION

• Maintain at least 4 tight wraps of wire rope on the drum at

all times. Refer to Dwg. MHP0498.

Install the winch such that the wire rope, when at the take-off

angle limits, shown in Dwg. MHP1404, does not contact the

mounting surface.

DANGER

• Exceeding the wire rope take-off angles will cause the wire

rope to come into contact with the winch frame supports

resulting in damage to the wire rope and winch.

Summary of Contents for ManRider force5 FA5AMR-LAK1

Page 39: ...39 WINCH CROSS SECTION DRAWING ...

Page 40: ...40 WINCH ASSEMBLY PARTS DRAWING ...

Page 42: ...42 MOTOR ASSEMBLY PARTS DRAWING ...

Page 44: ...44 DISC BRAKE ASSEMBLY PARTS DRAWING ...

Page 48: ...48 LEVER OPERATED CONTROL VALVE ASSEMBLY PARTS DRAWING ...

Page 50: ...50 PENDANT OPERATED PILOT CONTROL VALVE ASSEMBLY PARTS DRAWING ...

Page 52: ...52 REMOTE PENDANT ASSEMBLY PARTS DRAWING ...

Page 54: ...54 SHUTTLE VALVE ASSEMBLY PARTS DRAWING ...

Page 56: ...56 EMERGENCY STOP AND OVERLOAD ASSEMBLY PARTS DRAWING ...

Page 64: ...64 SERVICE NOTES ...

Page 65: ...65 SERVICE NOTES ...