2

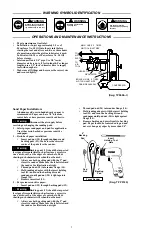

WARNING SYMBOL IDENTIFICATION

Always wear eye protection

when operating or perform-

ing maintenance on this tool.

WARNING

WARNING

Always wear hearing

protection when operating

this tool.

Read this manual before

operating tool.

WARNING

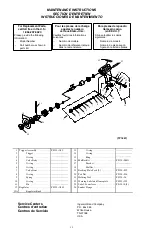

OPERATIONS AND MAINTENANCE INSTRUCTIONS

•

90 psig maximum at tool inlet.

•

Lubrication -- Inject approximately 1.5 cc of

Powerforce No. 50 Oil into the air inlet before

starting the tool and after each two or three hours

of operation, unless the air line lubricator is used.

Lubricate with 1.5 cc of Powerforce No. 50 Oil

before storage.

•

Inlet connection is 1/4” pipe. Use 3/8”

inside

diameter air hose up to 8 feet in length. For longer

lengths, use a 1/2”

inside

diameter hose to supply

tool with enough air.

•

Make sure all fittings and hoses are the correct size

and secured tightly.

MAIN LINES 3 TIMES

AIR TOOL INLET SIZE

TO

AIR

SYSTEM

TO

AIR

TOOL

LUBRICATOR

REGULATOR

FILTER

BRANCH LINE 2 TIMES

AIR TOOL INLET SIZE

DRAIN REGULARLY

COMPRESSOR

(Dwg. TPD905--1)

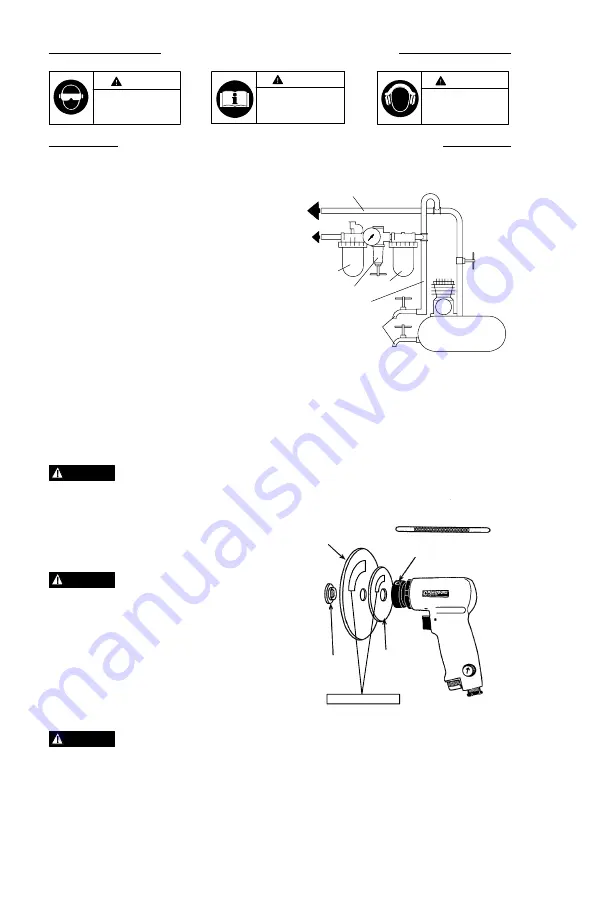

Sand Paper Installation:

Aluminum oxide, resin bond abrasive paper is

recommended. Paper can have 7/8” diameter

center hole or have pressure sensitive adhesive.

Warning

Disconnect the air supply before

servicing or changing the sanding pads.

1. Select proper sandpaper and pad for application.

Use either resin backed or pressure sensitive

sandpaper.

2. Resin back paper installation:

•

Insert pad nut (20) through sandpaper and

backing pads (19). Make sure the recessed

center of the pads face the sander.

Warning

Backing pads (19) should be inspected

for signs of irregularities such as fractures, excessive

wear, nicks, cuts, at the edges of center hole. Pads

showing such characteristics should not be used.

•

Always use both packing pad with the 3” pad

closest to sander. Make sure the label is toward

the sander. See illustration at right.

•

Thread pad nut (20) into sander flange (24).

•

Hold sanding adapter with the insert holding

tool (21) and turn the backing disc and

sandpaper until pad nut (20) is tight against

flange (24).

•

Remove insert tool (21).

3. For pressure sensitive paper:

•

Insert pad nut (20) through backing pads (19).

Warning

Backing pads (19) should be inspected

for signs of irregularities such as fractures, excessive

wear, nicks, cuts, at the edges of center hole. Pads

showing such characteristics should not be used.

•

Always use both packing pad with the 3” pad

closest to sander. Make sure the label is toward

the sander. See illustration at right.

•

Thread pad nut (20) into sander flange (24).

•

Hold sanding adapter with the insert holding

tool (21) and turn the backing disc and

sandpaper until pad nut (20) is tight against

flange (24).

•

Remove backing and press firmly to backing

pad. Paper should be centered onto pad and

not over hang any edges by more than 1/4”.

(Dwg. TP PF150)

5”

Backing

Pad

Insert

Holding Tool

Here

Pad

Nut

3”

Backing

Pad

HIGH

SPEED

LOW

SPEED

Faces Sander