Refer all communications to the nearest Ingersoll--Rand

Office or Distributor

Ingersoll--Rand Company 2002

Printed in Taiwan, R.O.C.

04579231

Form P7603

Edition 1

November, 2002

OPERATION AND MAINTENANCE MANUAL

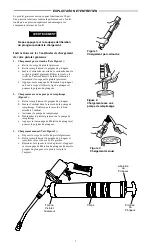

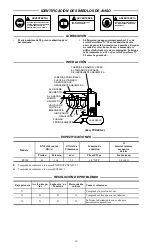

FOR PF900 AIR POWERED GREASE GUN

CAUTION

NOTICE

Model PF900 Grease Gun is designed for injecting grease into grease fittings for home use.

IMPORTANT SAFETY INFORMATION ENCLOSED -- SAVE THESE INSTRUCTIONS

READ AND UNDERSTAND THIS MANUAL BEFORE OPERATING THIS PRODUCT

IT IS YOUR RESPONSIBILITY TO MAKE THIS SAFETY INFORMATION

AVAILABLE TO OTHERS THAT WILL OPERATE THIS PRODUCT

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD

RESULT IN INJURY

PLACING TOOL IN SERVICE

•

Always install, operate, inspect and maintain this

product in accordance with all applicable standards

and regulations (local, state, country, federal, etc.).

•

Always use clean, dry air at 90 psig (6.2 bar/620 kPa)

maximum air pressure at the inlet. Higher pressure

may result in hazardous situations including excessive

speed, rupture, or incorrect output torque or force.

•

Be sure all hoses and fittings are the correct size and

are tightly secured. See Dwg. TPD905--2 for a typical

piping arrangement.

•

Ensure an accessible emergency shut off valve has

been installed in the air supply line, and make others

aware of its location.

•

Do not use damaged, frayed or deteriorated air hoses

and fittings.

•

Keep clear of whipping air hoses. Shut off the

compressed air before approaching the whipping

hose.

•

Always turn off the air supply and disconnect the air

supply hose before installing, removing or adjusting

any accessory on this tool, or before performing any

maintenance on this tool.

•

Do not lubricate tools with flammable or volatile

liquids such as kerosene, diesel or jet fuel. Use only

recommended lubricants.

•

Keep work area clean, uncluttered, ventilated and

illuminated.

•

Do not remove any labels. Replace any damaged label.

USING THE TOOL

•

Always wear eye protection when operating or

performing maintenance on this tool.

•

Always use Personal Protective Equipment

appropriate to the tool used and material worked.

This may include dust mask or other breathing

apparatus, safety glasses, ear plugs, gloves, apron,

safety shoes, hard hat and other equipment.

•

This tool is not designed for working in explosive

environments, including those caused by fumes and

dust, or near flammable materials.

•

This tool is not insulated against electric shock.

•

Power tools can vibrate in use. Vibration, repetitive

motions or uncomfortable positions may be harmful

to your hands and arms. Stop using any tool if

discomfort, tingling feeling or pain occurs. Seek

medical advice before resuming use.

•

Keep body stance balanced and firm. Do not

overreach when operating this tool. Anticipate and be

alert for sudden changes in motion, reaction torques,

or forces during start up and operation.

•

To avoid accidental starting -- ensure tool is in “off”

position before applying air pressure, avoid throttle

when carrying, and release throttle with loss of air.

•

Ensure work pieces are secure. Use clamps or vises to

hold work piece whenever possible.

•

Do not carry or drag the tool by the hose.

•

Do not use power tools when tired, or under the

influence of medication, drugs, or alcohol.

•

Never use a damaged or malfunctioning tool or

accessory.

•

Do not modify the tool, safety devices, or accessories.

•

Do not use this tool for purposes other than those

recommended.

•

Use accessories recommended for PowerForce by

Ingersoll--Rand.

The use of other than genuine Powerforce by Ingersoll--Rand replacement parts may result in safety hazards, decreased

tool performance, and increased maintenance, and may invalidate all warranties.

Repairs should be made only by an authorized Powerforce Servicenter. Call toll free 1 (866) 207-6923.

US

F

E